Energy saving hatching machine

A chassis and fan motor technology, applied in poultry incubators, applications, poultry industry, etc., can solve the problems that cannot be separated into hatching and hatching at the same time, hindering the improvement of the structure of the incubator and the reduction of manufacturing costs, and the uniform heat consumption of the incubator Problems such as TV large, etc., to achieve the effect of easy uniformity and stability of the temperature inside the machine, improve the hatching effect, save the effect of fan motor and deceleration device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

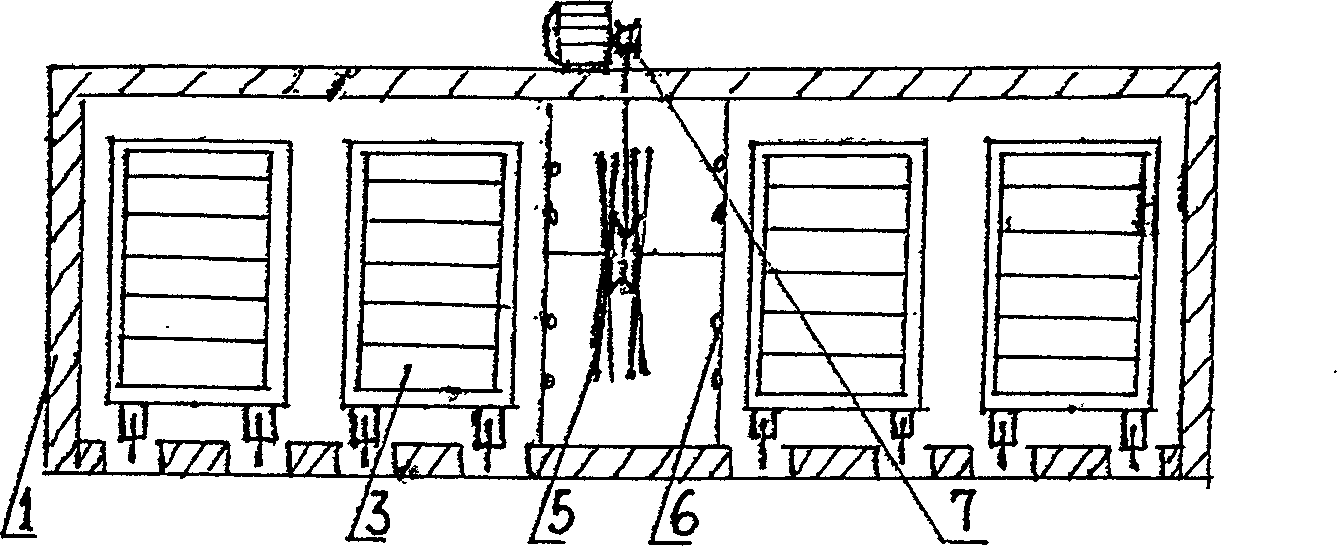

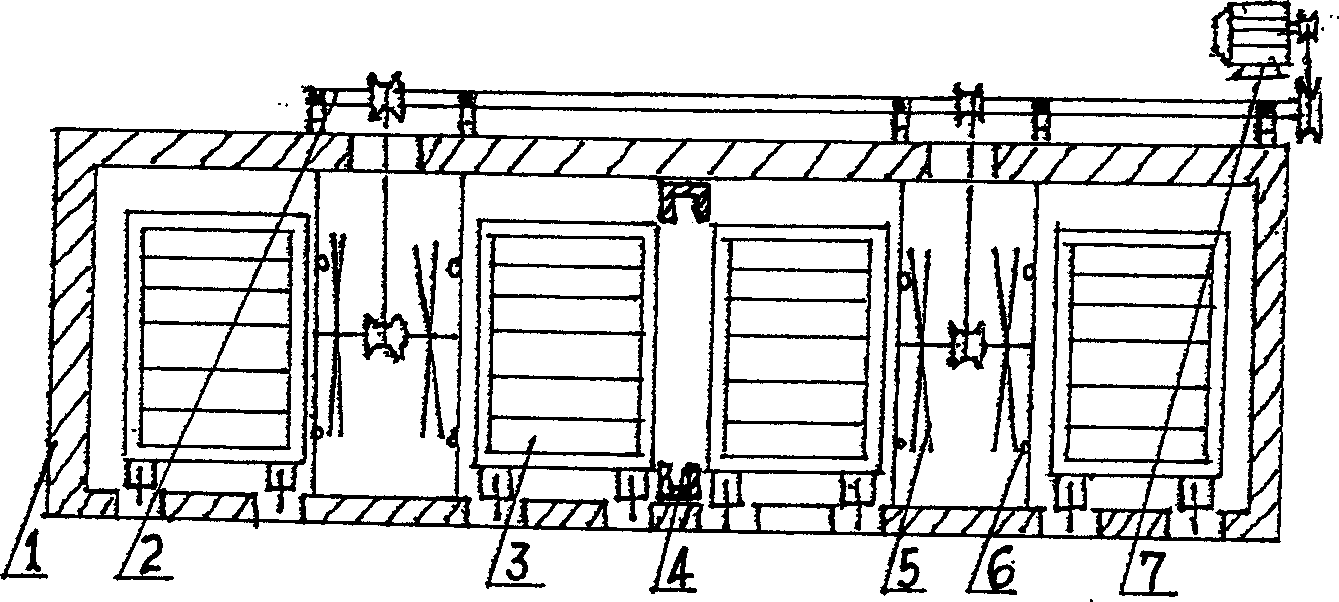

[0031] Look again Figure 4 The second embodiment of the energy-saving incubator of the present invention. Compared with the first embodiment, the only difference is that no transmission shaft [2] is provided, but 2 fan motors [7] are installed, and a reduction device is required accordingly. versus figure 2 similar. This embodiment saves less power, and the increased motor and speed reducer increase the manufacturing cost of the machine.

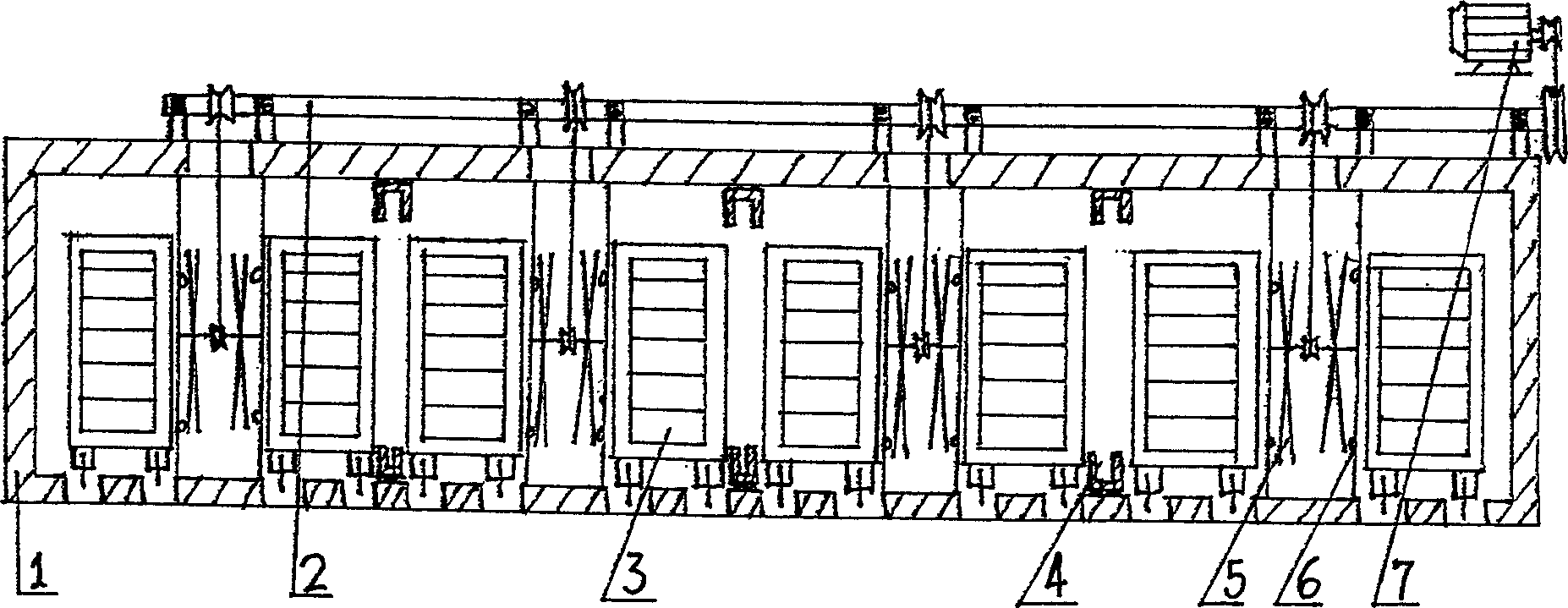

[0032] Look again Figure 5 The third embodiment of the energy-saving incubator of the present invention. Compared with the first embodiment, a uniform heating fan is installed between each adjacent egg cart [3] in the chassis [1]. [5], but not equipped with an occlusal device that can be installed with movable partitions [4], others are similar to figure 2 similar. This embodiment unnecessarily increases the uniform heat fan [5], which increases the load of the fan motor [7], thereby reducing power saving, and at the same time increasing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com