Ceramic material and process for manufacturing

A ceramic material and slurry technology, used in the field of plastic surgery and dentistry, can solve problems such as insufficient mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] This example describes the preparation of a ceramic material consisting of calcium aluminate hydrate and varying amounts of titanic acid, as well as the mechanical properties of this material.

[0096] The ingredients we selected were purchased from Lafarge Aluminates' Ternal White . This is an Al 2 o 3 / CaO is about 70 / 30 calcium aluminate, however, any other similar calcium aluminate powder will give similar results.

[0097] These powder particles were reduced in size by ball milling. 90% of the ground powder is smaller than 10 μm.

[0098] Grinding is accomplished in a rotating cylindrical shaped vessel, which is filled to one third of its volume with powder and approximately one third of its volume to inert silicon nitride grinding balls approximately 10 mm in diameter. The grinding liquid is isopropanol. The total milling time was 3 days.

[0099] After grinding, the ground bodies were sieved and the alcohol was evaporated to dryness. The milled powder w...

Embodiment 2

[0107] This example describes hydrated CA materials incorporating various amounts of calcium phosphate and their mechanical properties.

[0108] The Ternal White type CA powder of Lafarge Aluminates was prepared according to the same procedure as in Example 1.

[0109] Calcium phosphate powder (Ca5(PO 4 ) 3 OH) in proportions of 10, 20 and 50 wt.%. CA prepared in a similar manner without the addition of a phosphate additive was used as a control. The same reagent as in Example 1 was added to water. Its w / c ratio was 0.4 relative to the weight of the powder.

[0110] As in Example 1, the powder-water mixture was cured at 37°C in a water-saturated environment in a container capable of holding about 10 g of material.

[0111] Hardness results are shown in Table 3. As shown in the table, the positive effect of the calcium phosphate additive on hardness was evident after two weeks of curing. Calcium phosphate additives enhance hardness.

[0112] Material compositio...

Embodiment 3

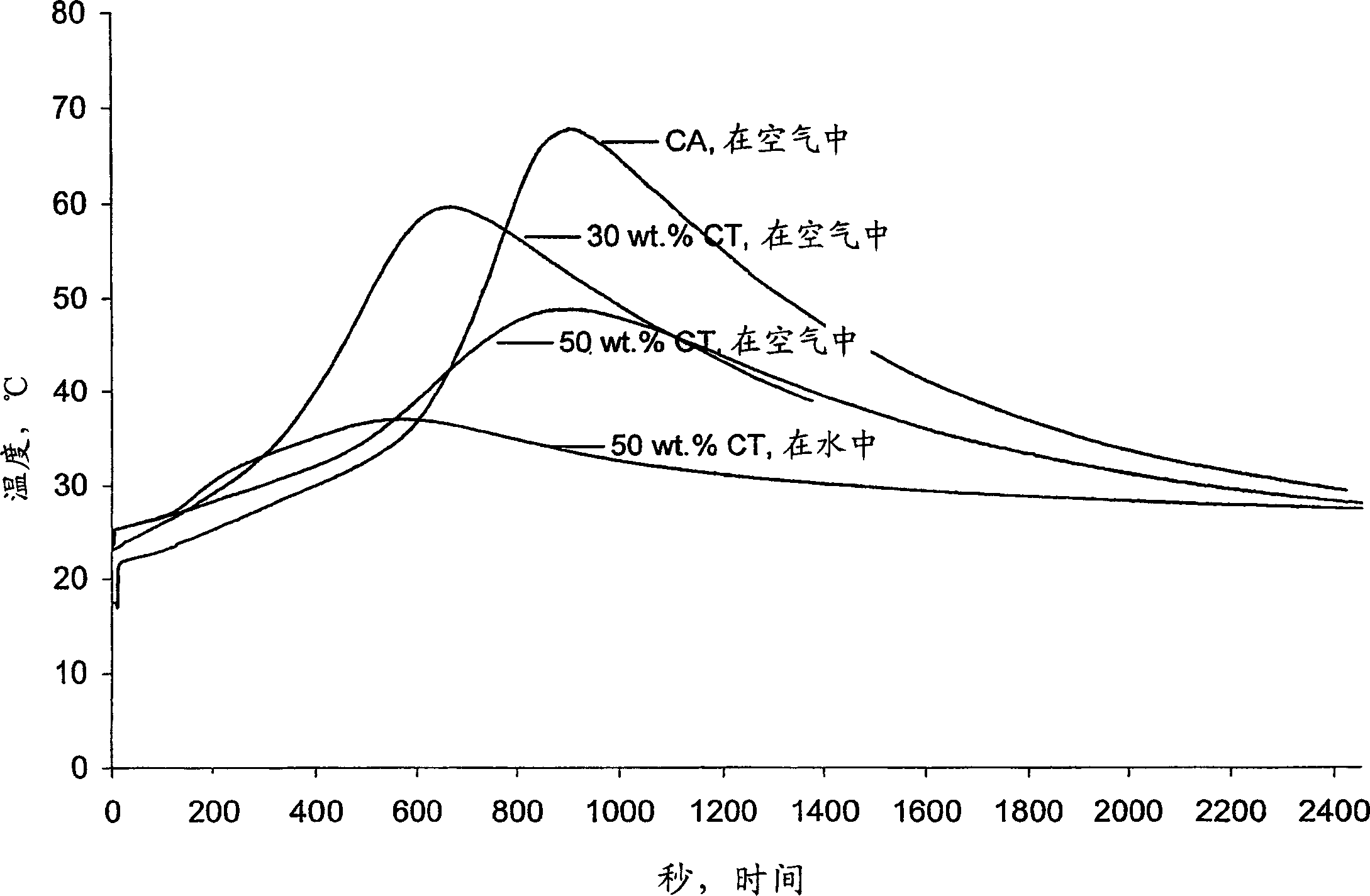

[0114] This example illustrates that calcium titanate (CT) additives can reduce temperature generation during CA curing. The Ternal White type CA powder of Lafarge Aluminates was prepared according to the same procedure as in Example 1. Powder mixtures containing 30 wt.% and 50 wt.% titanate were prepared in the same way.

[0115] The powder mixture was mixed with deionized water, and the weight ratio of water to CA powder was kept constant at 0.5.

[0116] For all powder mixtures, an accelerator LiCl in the form of a lithium salt was added in deionized water. This increases the curing time to approximately 10 minutes. To account for the influence of surrounding media, curing was done in air and water.

[0117] The water-powder mixture solidifies in shaped containers, each containing approximately 10 g of the mixture. During the curing of the ceramic, the temperature at the center of the ceramic body was measured with a thermocouple. figure 1 CA with 0, 30 or 50 wt.% CT, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com