Processing method for processing easy breaking paper

A processing method and technology for processing paper, applied in the direction of roll-resistant paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

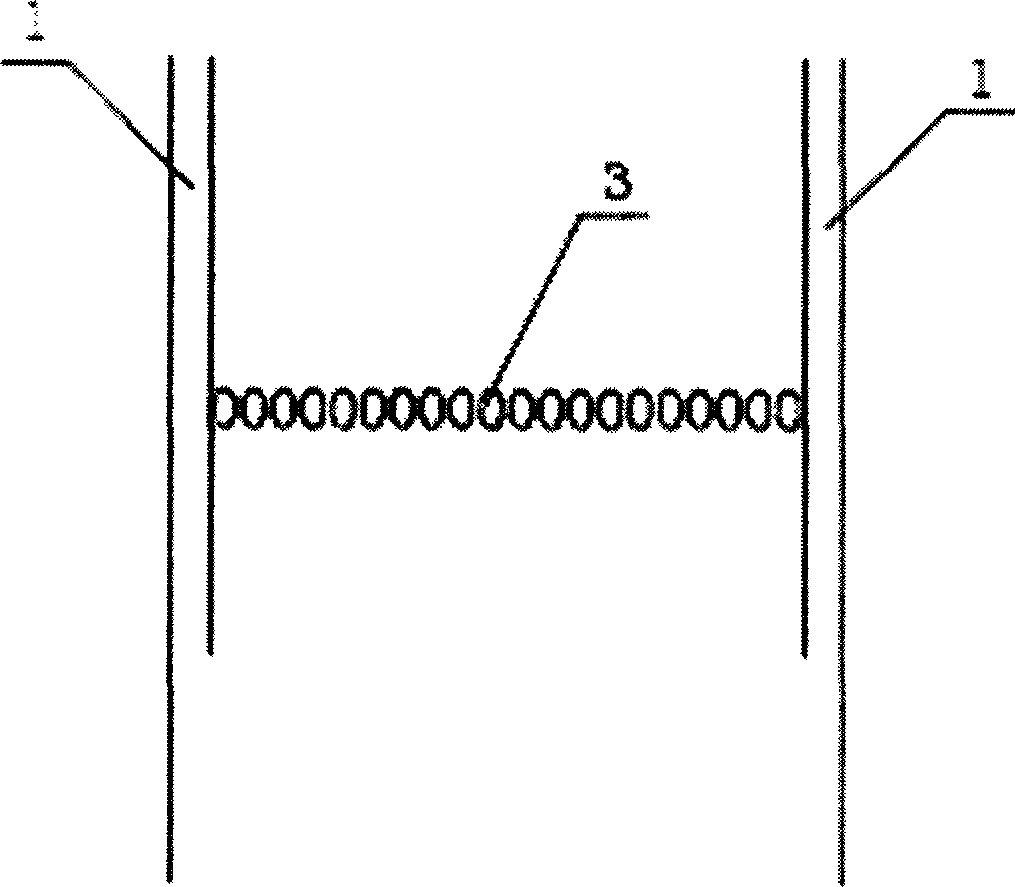

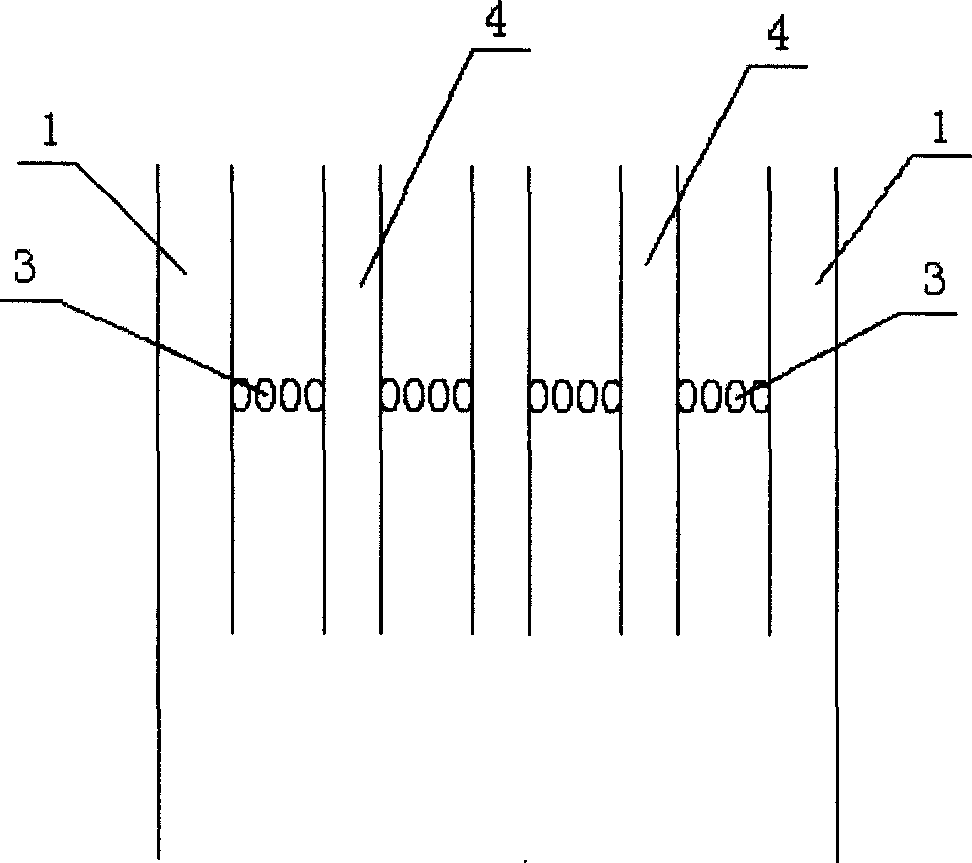

[0011] Such as figure 1 and figure 2 As shown, in a preferred embodiment of the present invention, the processing method of this extremely fragile processed paper of the present invention includes the step of performing dotted line knife cutting or punching on the paper, wherein the paper has a cut edge As for the side thread part, the paper includes more than two side-by-side narrow-width slitting paper strips, wherein, firstly, between the dotted line incision 2 or the hole-shaped incision 3, the uncut or punched paper with a width of 2mm to 20mm is reserved. The paper part 4 of the hole; secondly, widen the width of the trimmed edge 1 of the paper, the width of the trimmed edge 1 is 1 mm to 20 mm, and make the widened trimmed edge 1 not be cut or punched; finally, For the widened side wire 1 that is not cut or punched, it is cut off by the cutting process behind the cutting or punching process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com