Unloading and cleaning system for hydraulic unloading imersion pump oil filling riser

A technology of submersible oil pump and tank stripping, which is applied to liquid flow control devices, liquid distribution, transportation or transfer devices, liquid distribution, etc. It can solve the problems that the bottom oil cannot be taken out, the loss of oil and gas is large, and the oil recovery rate is affected. Achieve the effects of low noise, improved oil unloading speed and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

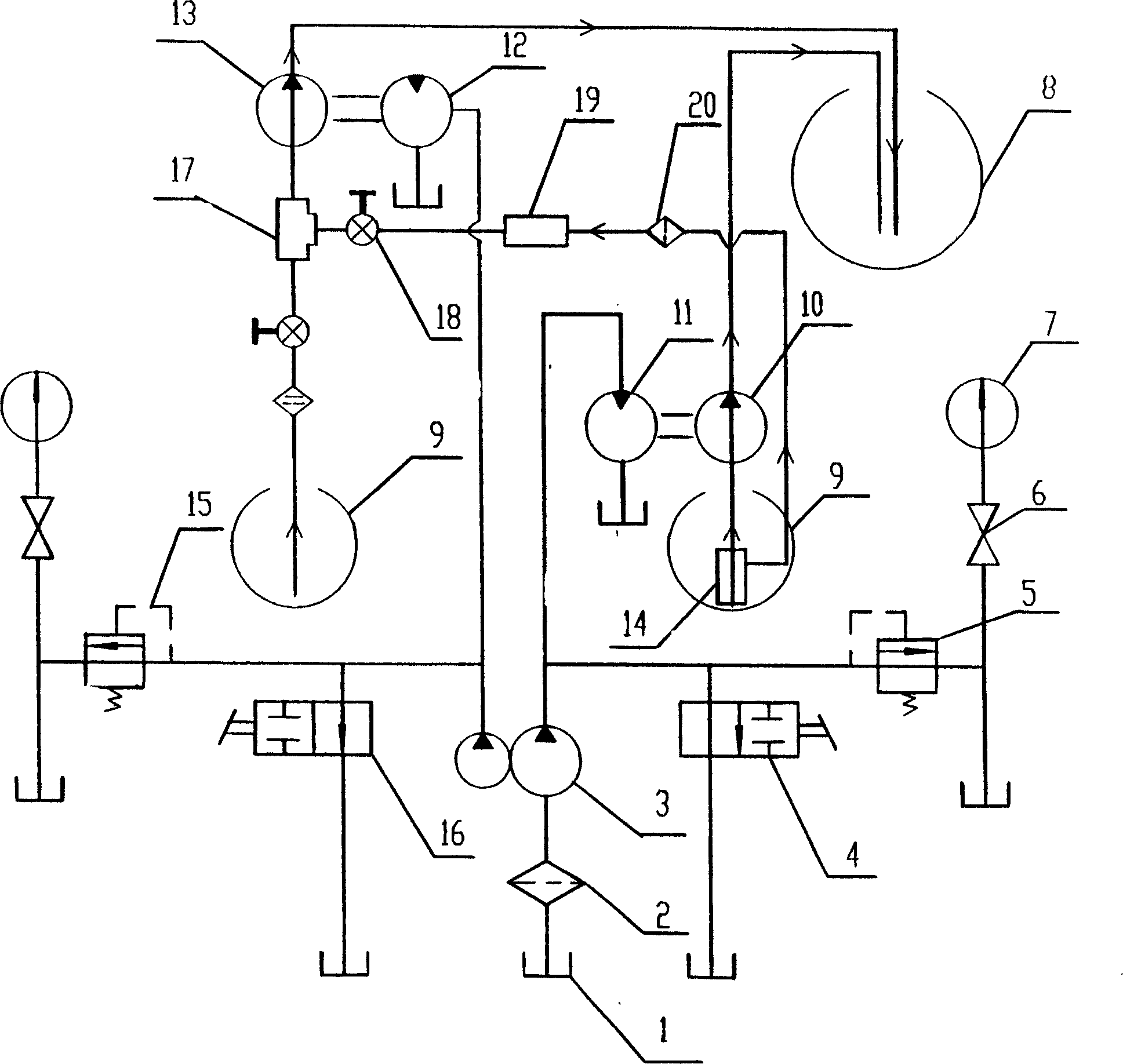

[0015] As shown in the figure, a hydraulic unloading submersible pump crane tube unloading tank stripping system is an innovation based on the aforementioned ZL99234121.3 patent. This innovation is mainly based on the existing positive pressure unloading system. A negative pressure stripping device is added to the oil system. The unloading and stripping system of the crane pipe of the hydraulic unloading submersible pump is composed of a crane pipe assembly, a submersible pump system, an oil pressure station and a stripping system, and is characterized in that:

[0016] A. The oil pressure station is a hydraulic power output mechanism consisting of an explosion-proof motor, a duplex pump 3, two high-pressure oil pipes, and an oil return pipe located in the oil tank 1;

[0017] B, the described submersible pump system is composed of submersible pump 10, trousers-shaped fork pipe 14, gear motor 11, hydraulic station based on duplex pump 3, high-pressure oil pipe, and oil return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com