Double-jaw diagonal wrench

A technology of adjustable wrench and wrench body, applied in the field of adjustable wrench, can solve the problems of the working part of the wrench being too large, unsuitable for use, affecting the operation, etc., and achieve the effects of no slippage, convenient opening adjustment, and large torque resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail through the embodiments below in conjunction with the accompanying drawings.

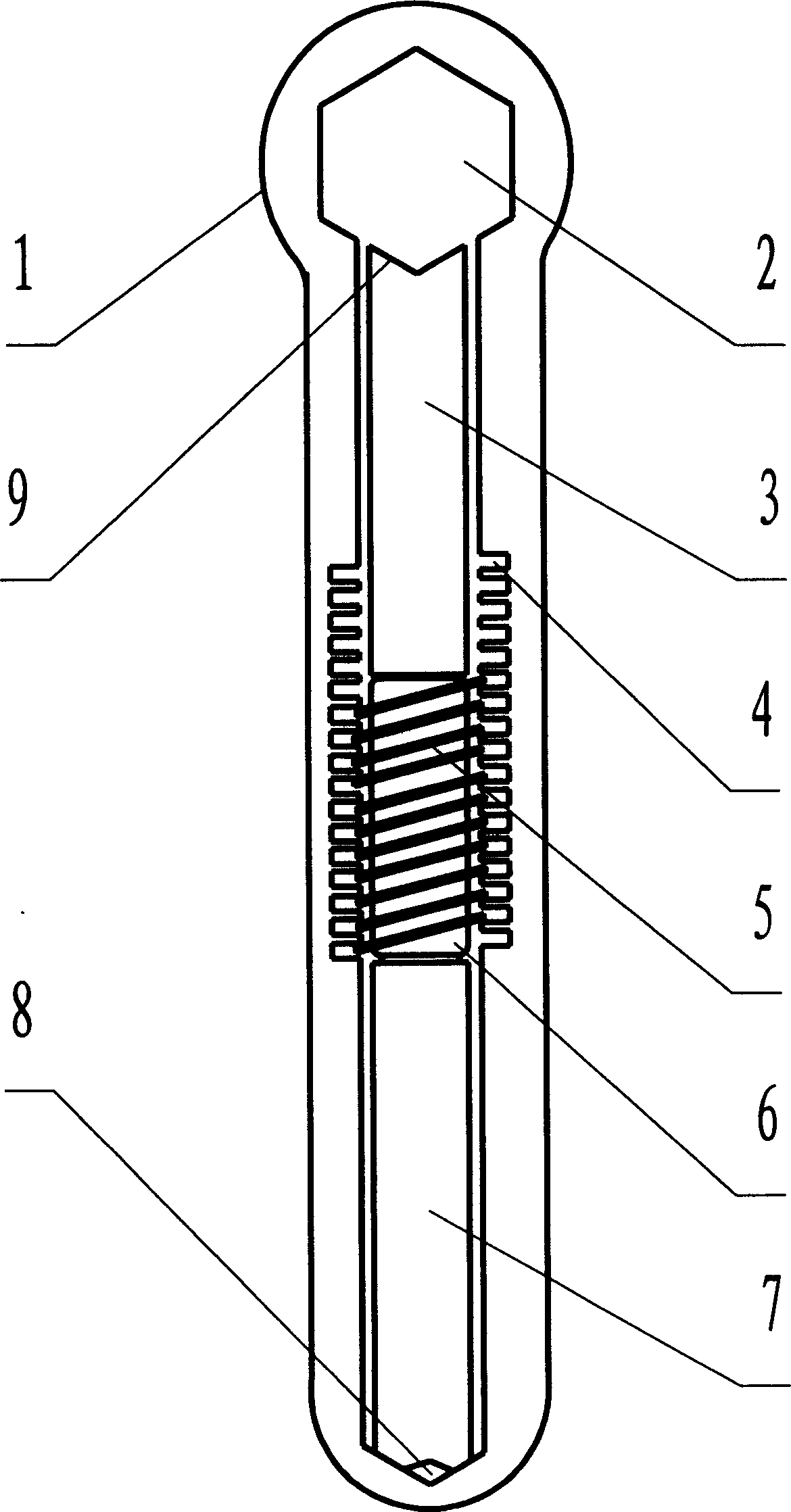

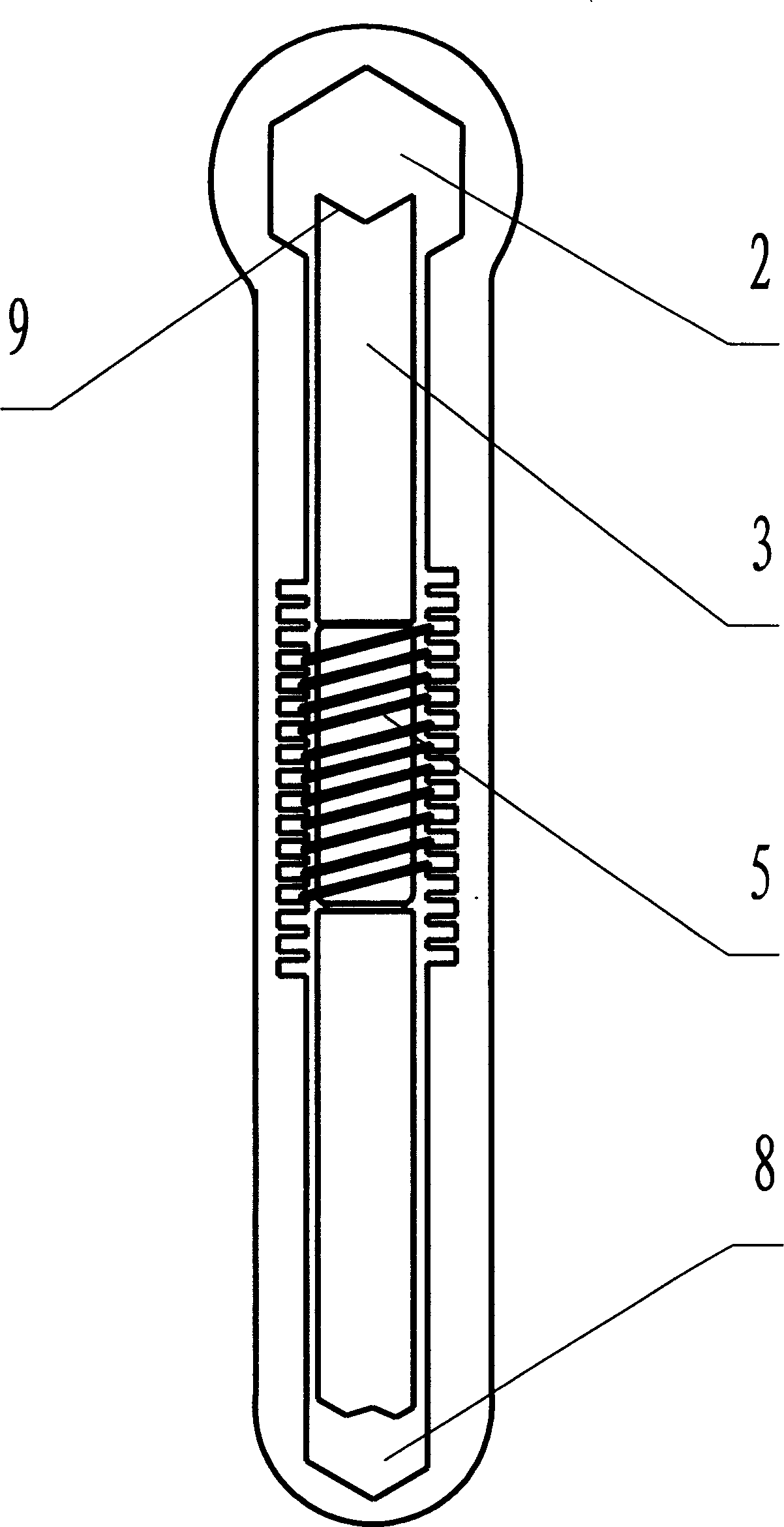

[0013] see figure 1 , This double-headed adjustable wrench comprising a wrench body 1, a nut-shaped opening and an opening adjusting device thereof, the nut-like opening is a through hole 2, 8 that is located at two ends of the vertical wrench body 1 and matches different nut shapes. There is a strip-shaped groove in the long axis of the pull body 1, and a movable strip is placed therein. The end shapes of the two ends of the movable strip match the shapes of the through-hole walls at both ends respectively, forming a complete through-hole wall. The present embodiment is hexagonal through hole 2,8 (certainly, through hole 2,8 also can be set to other shapes as required, such as pentagonal etc.), from figure 1 As can be seen in the figure, the four sides of the big mouth end are complete, and a part of the other two sides is formed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com