Catalyst oxide for changing quality of fossil fuel

A technology for oxidation catalysts and fossil fuels, used in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, etc., to reduce the amount of black smoke and NOX.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] In CeO 2 35.7% by weight, ThO 2 20% by weight, ZrO 2 20% by weight, SnO 2 0.3 wt%, CuO 2 0.2% by weight, CoO 0.7% by weight, MgO 2 8.8% by weight of oxidized clay was mixed with 15% by weight, and crushed to a particle size of 250 mesh.

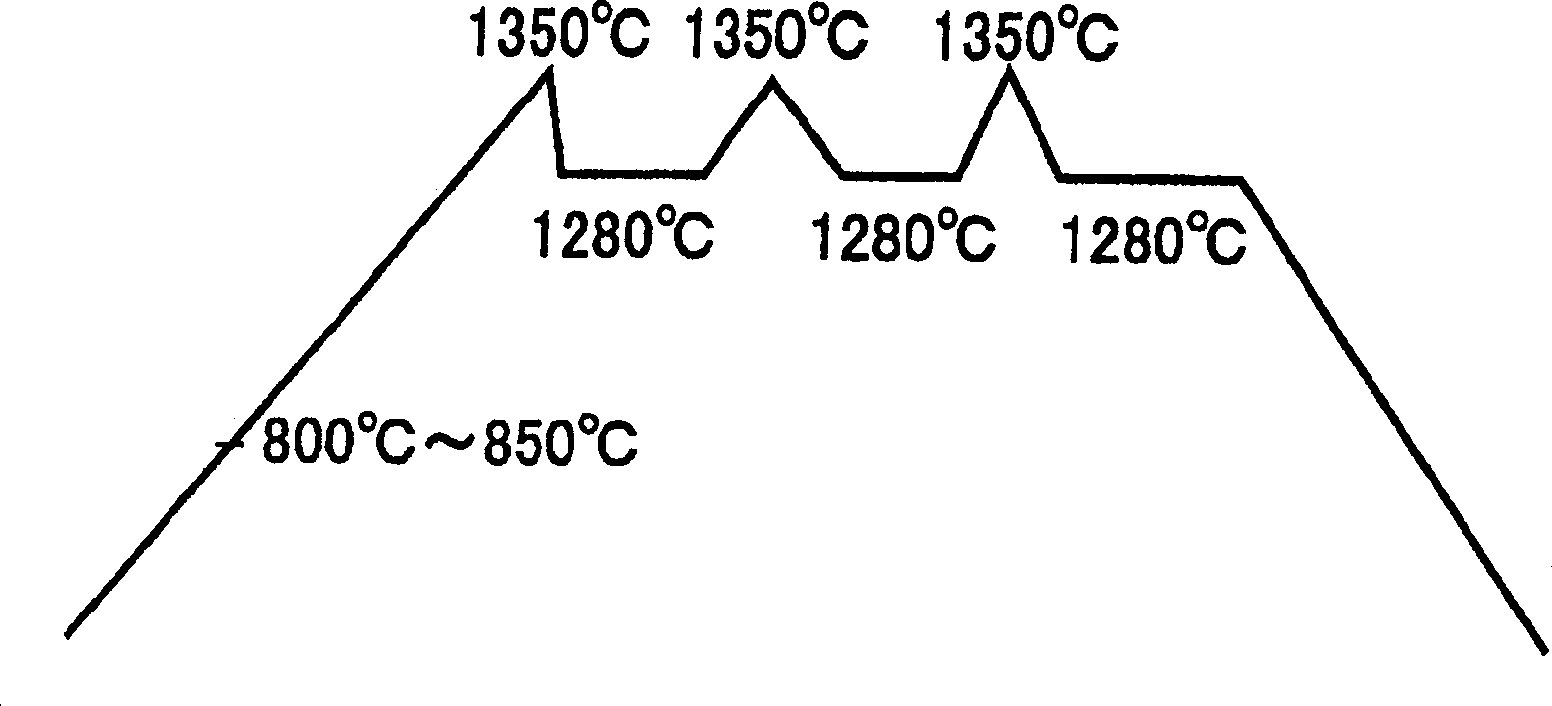

[0055] Add water to the above mixture, mix and shape, form a reduced burning state in a reduction furnace at 800-850°C, and heat up to 1350°C for sintering. burning conditions such as figure 1 As shown, it takes 4 hours to heat up to 1350°C, take 30 minutes to cool down to 1280°C, keep at 1280°C for 3 hours, take 30 minutes to heat up to 1350°C, take 30 minutes to drop to 1280°C and keep for 3 hours, use The temperature was raised to 1350° C. in 30 minutes, lowered to 1280° C. in 30 minutes and sintered for 4 hours.

[0056] The ceramic catalyst thus obtained can be used in various shapes. In the case of a spherical shape, a size with a diameter of about 8 to 10 mm has a large contact area, so the effect is good.

Embodiment 2

[0058] 15.7 wt% of oxidized clay is mixed with Ce27 wt%, Co7 wt%, Th20 wt%, Zr18 wt%, Mg4 wt%, Sn1.2 wt%, Pd4.8 wt%, Ni0.9 wt%, Mo1.4 wt% %, crushed to 250 mesh.

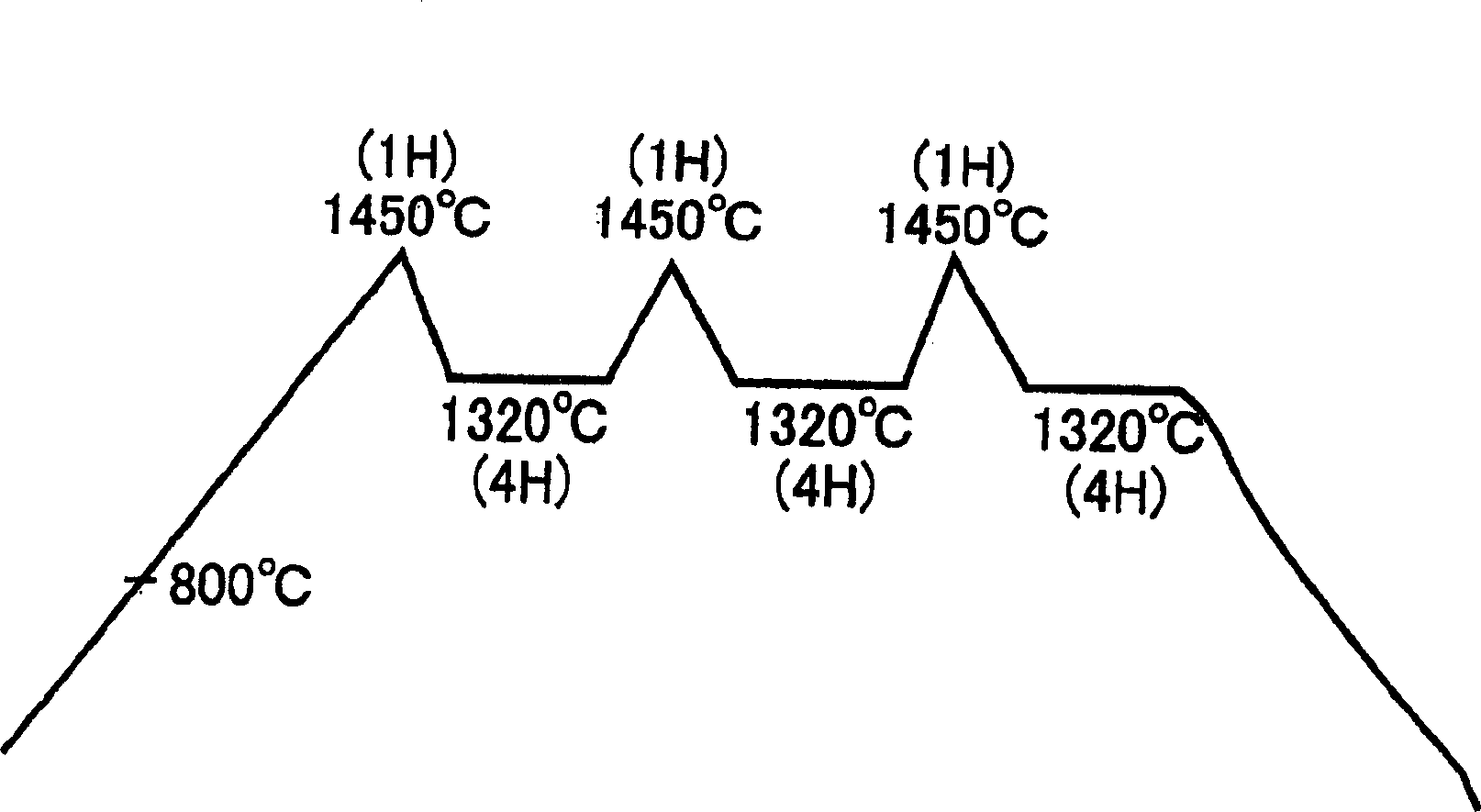

[0059] Add water to the above mixture, mix and shape, form a reduced burning state at 800°C in a reduction furnace, and heat up to 1450°C for sintering. burning conditions such as figure 2 As shown, it takes 3 hours to raise the temperature to 1450°C, take 1 hour to raise the temperature to 1450°C, take 30 minutes to drop from 1450°C to 1320°C and keep it for 4 hours, take 30 minutes to raise the temperature to 1450°C and keep it for 1 hour, and take 30 minutes to drop To 1320°C and keep it for 4 hours, take 30 minutes to raise the temperature to 1450°C and keep it for 1 hour, take 30 minutes to drop to 1320°C and sinter for 4 hours.

[0060] The ceramic oxidation catalyst manufactured in the above-mentioned manner is spherical (8~10mm), and the catalyst that adds 50% by weight of palladium, 15% by weight of magn...

Embodiment 3

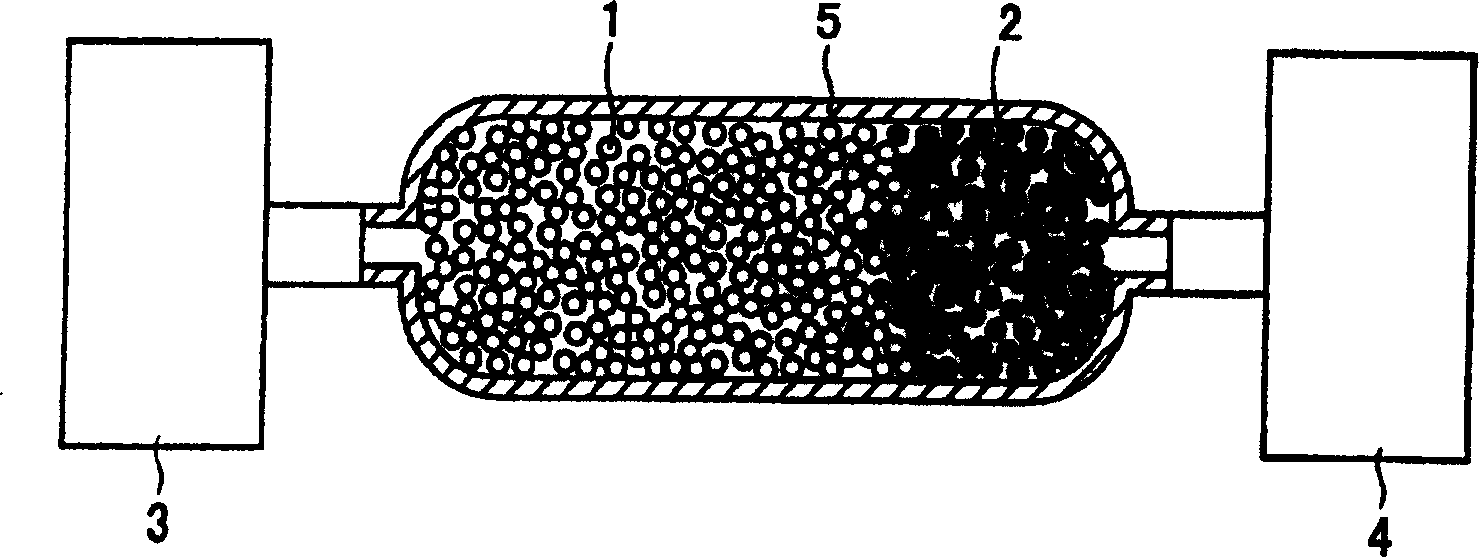

[0063] The ceramic oxidation catalyst 1 manufactured according to the above-mentioned embodiment 1 is made into a spherical shape (8-10 mm), such as image 3 As shown, the oxide ceramic catalyst coated with a platinum-rhenium catalyst within 2mm and increasing the total weight by about 20% by weight is filled into Mazuda (Mazda?) Diesel engine vehicles KC-WGE4T and KC-WGEAT ( 2t car) in the stainless steel container 5 connected to the piping between the light oil fuel tank 3 and the engine 4. The amount of black smoke, NO X The amount (g / kwh), the amount of CO (g / kwh), the amount of HC (g / kwh) and the amount of PM (g / kwh) were tested. The results are shown in Table 1 below.

[0064] Exhaust gas composition

CO

HC

NO X

PM

Akishima Laboratory Test Results

5.781

1.420

4.558

0.694

National benchmark value (2t vehicle)

9.200

3.800

7.800

0.960

Measured value before instal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com