Micro refrigerator and producing method thereof

A cooler and miniature technology, which is applied in the direction of thermoelectric devices, electric solid devices, semiconductor devices, etc., can solve the problems of device separation and limit the working efficiency of devices, achieve good consistency, realize array cooling, and achieve consistent and uniform sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

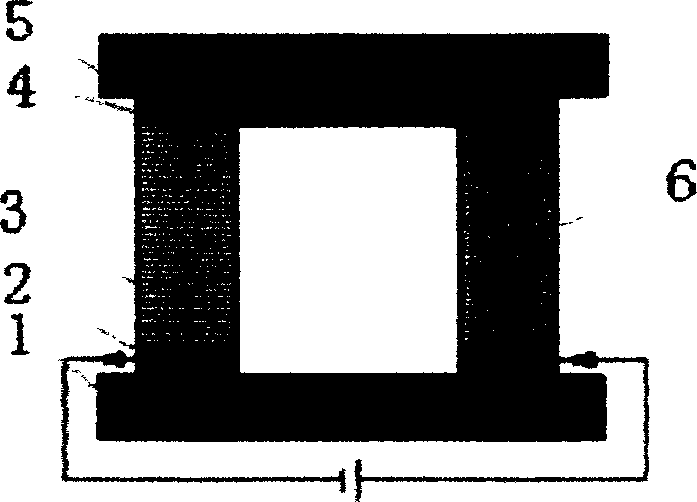

[0042] The invention adopts the combination of the electroless metal plating film forming process and the oxide isolation process to form a multi-stage miniature refrigerator. The refrigerator has a multi-layer structure, and the lowermost layer is a high-temperature area 1, and two metal layers 2 are respectively arranged on the high-temperature area 1, a P-type semiconductor 3 is arranged on one of the metal layers 2, and a P-type semiconductor 3 is arranged on the other metal layer 2. An N-type semiconductor 6 is arranged on it, an integral upper metal layer 4 is arranged on the P-type semiconductor 3 and the N-type semiconductor 6 , and a low-temperature region 5 is arranged on the upper metal layer 4 .

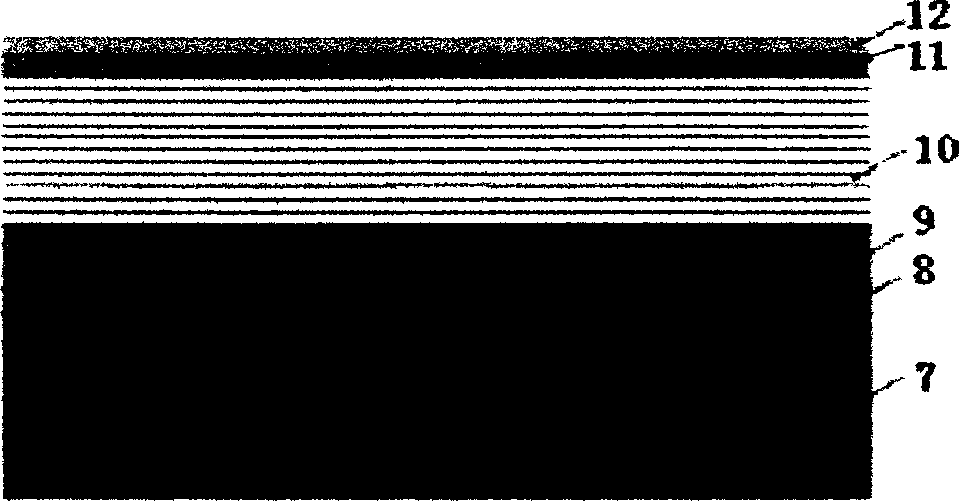

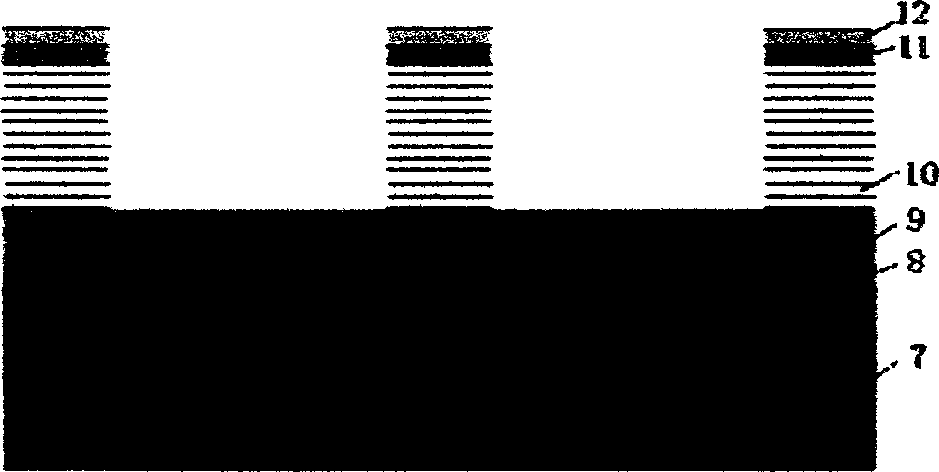

[0043] The concrete structure of this refrigerator is divided into upper and lower two parts; Layer 8, the first heavily doped layer 9 of P-type semiconductor is arranged at intervals on the undoped layer 8 of P-type semiconductor, and the first heavily doped layer 9 of P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com