Condensing unit for wasing dryer

A technology for laundry dryers and condensing devices, applied in washing devices, washing machines with containers, steam/steam condensers, etc., can solve problems such as no condensation efficiency, reduced drying performance, and uneven air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

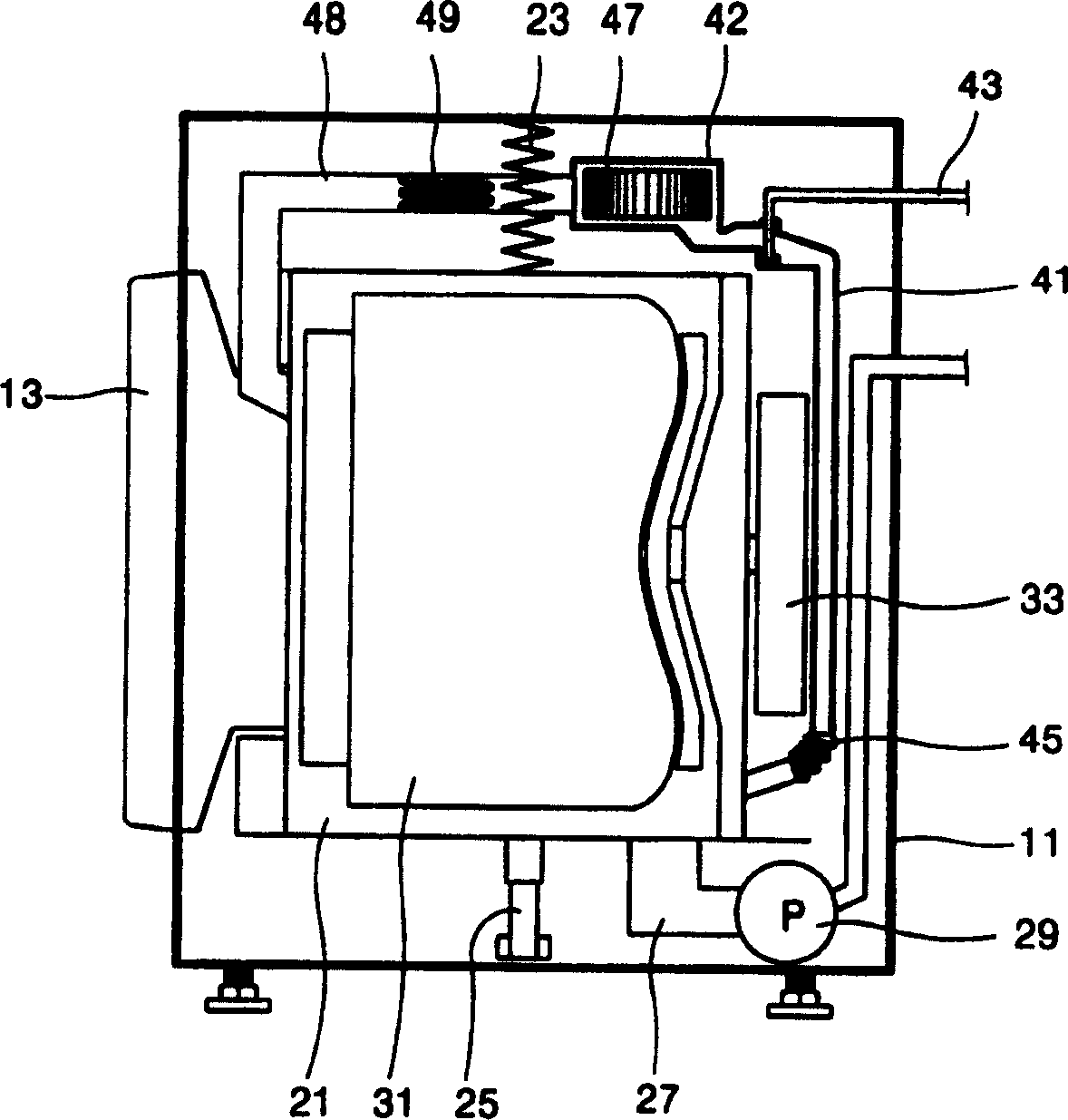

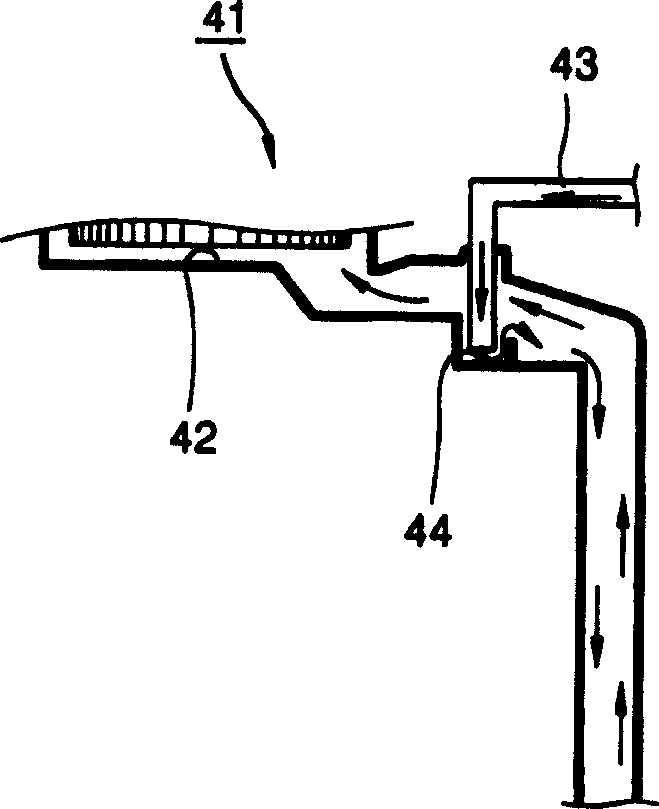

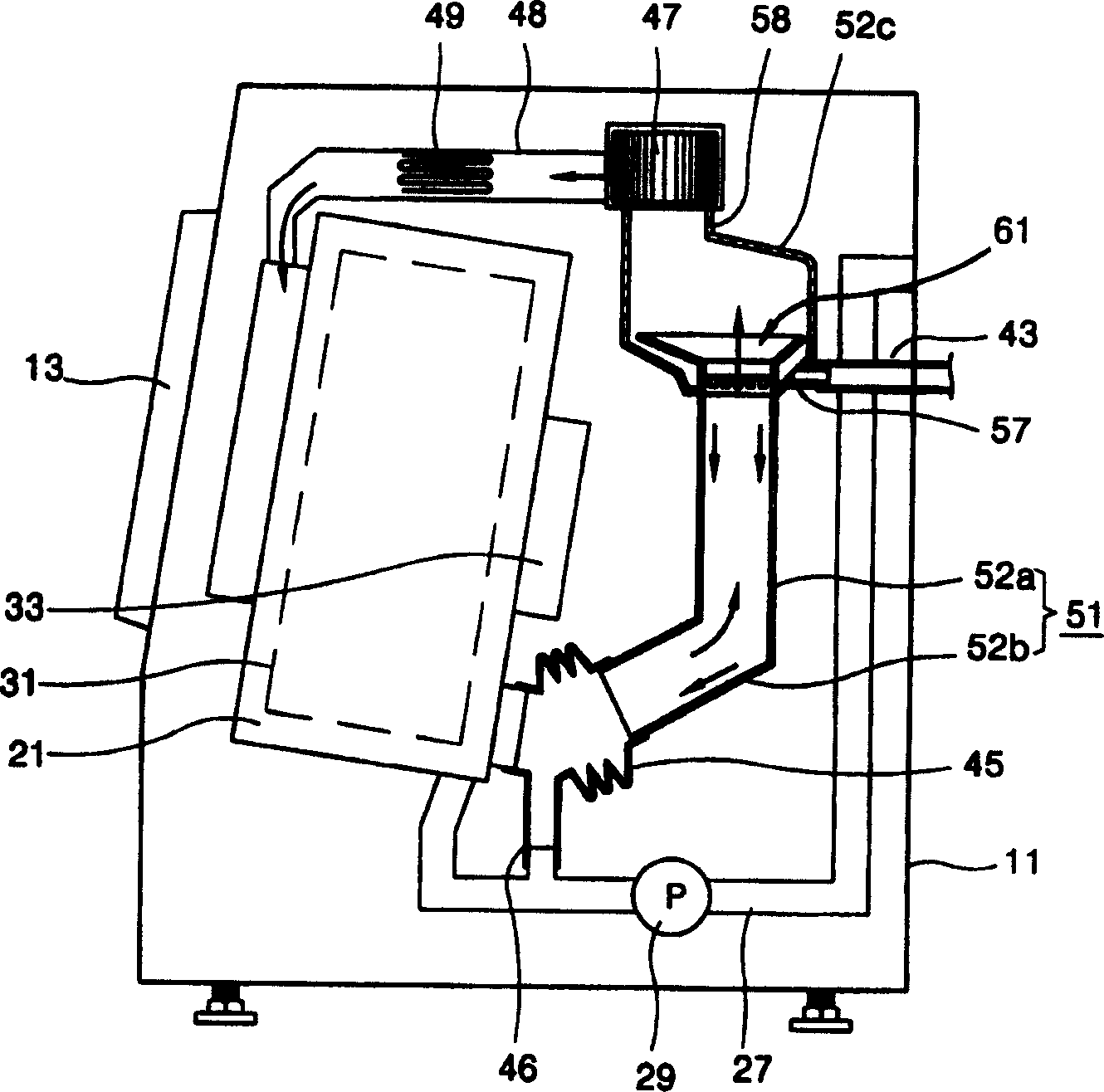

[0042] image 3 Showing the use state of the condensing device of the washing and drying machine according to the first embodiment of the present invention, Figure 4 yes image 3 An enlarged view of the main components of the Figure 5 yes image 3 perspective view of the chamber, while Figure 6 yes image 3 Perspective view of the condensate guide. Components having the same structure as the preceding components are denoted by the same reference numerals.

[0043] As shown in the figure, the washing and drying machine includes a housing 11 forming a receiving space therein, a water tub 21 inside the housing 11 for receiving washing water therein, a drum 31 rotatably disposed in the water tub 21, and A drum drive motor 33 for driving the drum 31 .

[0044] The bucket 21 has a box shape with one side open, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com