Ecological environment-friendly type wallboard with regeneration aggregate function and method of manufacture the same

A recycled aggregate, environmentally friendly technology, applied in building materials, sustainable waste treatment, solid waste management, etc., can solve the problems of low comprehensive utilization rate and utilization level of construction waste, low added value of utilization, etc., and improve the utilization return. efficiency, high value-added utilization, and outstanding functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

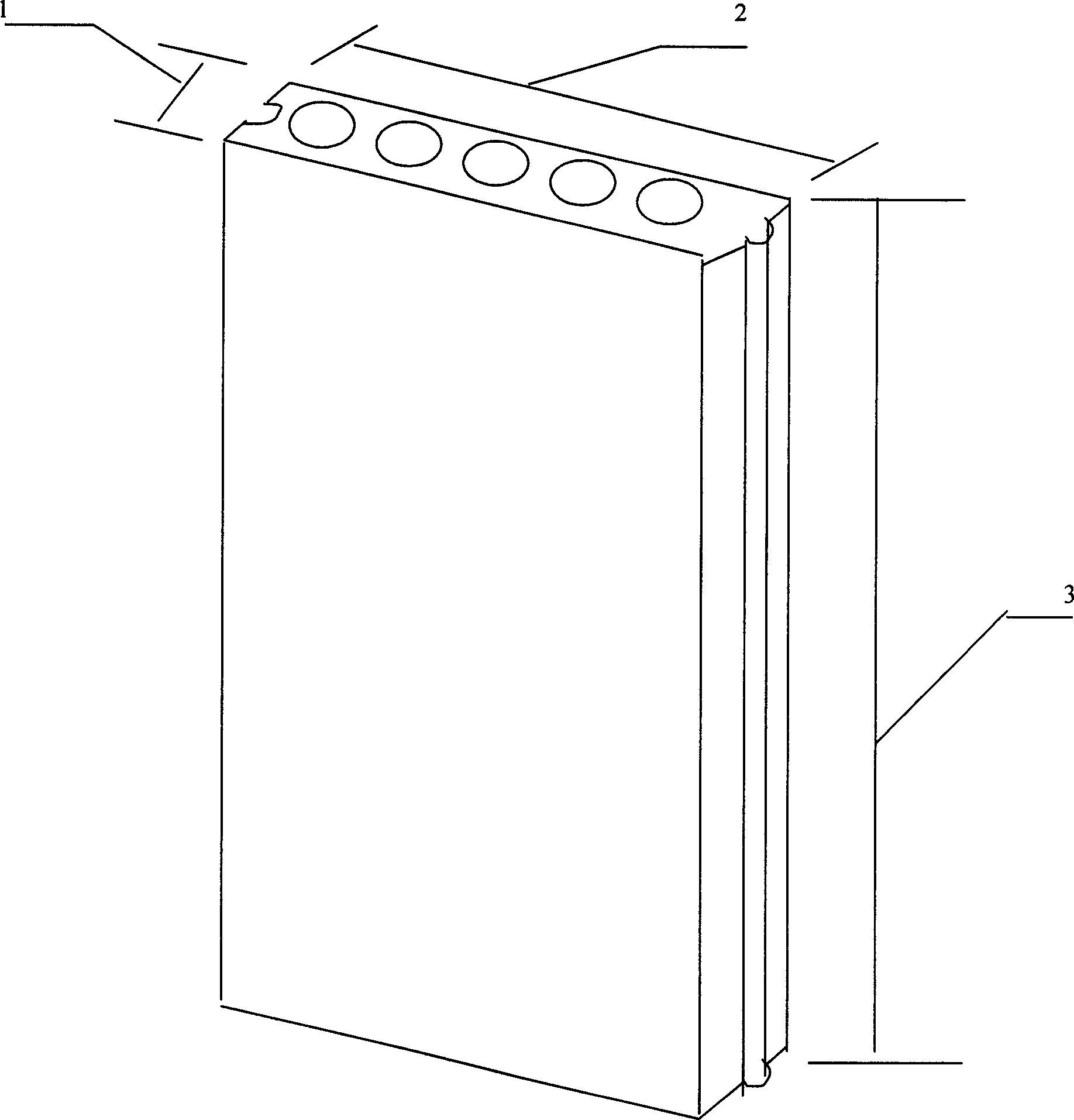

Embodiment 1

[0045] Production of recycled aggregate acoustic wall panels. The partition walls or household partition walls of houses and residences are mostly permanent partition walls constructed by construction companies, and the sound insulation performance requirements of the wall panels are relatively high and strict. Due to the needs of sound insulation, firmness, hanging, durability, and low cost, the product needs a certain density, which can be produced by making full use of recycled broken brick aggregates from construction waste. The specific method is 70-85% of recycled broken brick aggregate, 15-30% of ordinary Portland cement, and 1-3% of admixture. The products are mainly produced in specifications of 800-1200*495*90-190, and the density grade of the products Choose 1000-1200kg / m 3 class. Household wall panels use a double-row hole extrusion machine to produce 150-190 type double-row hole wall panels to improve the sound insulation level of the household walls and still h...

Embodiment 2

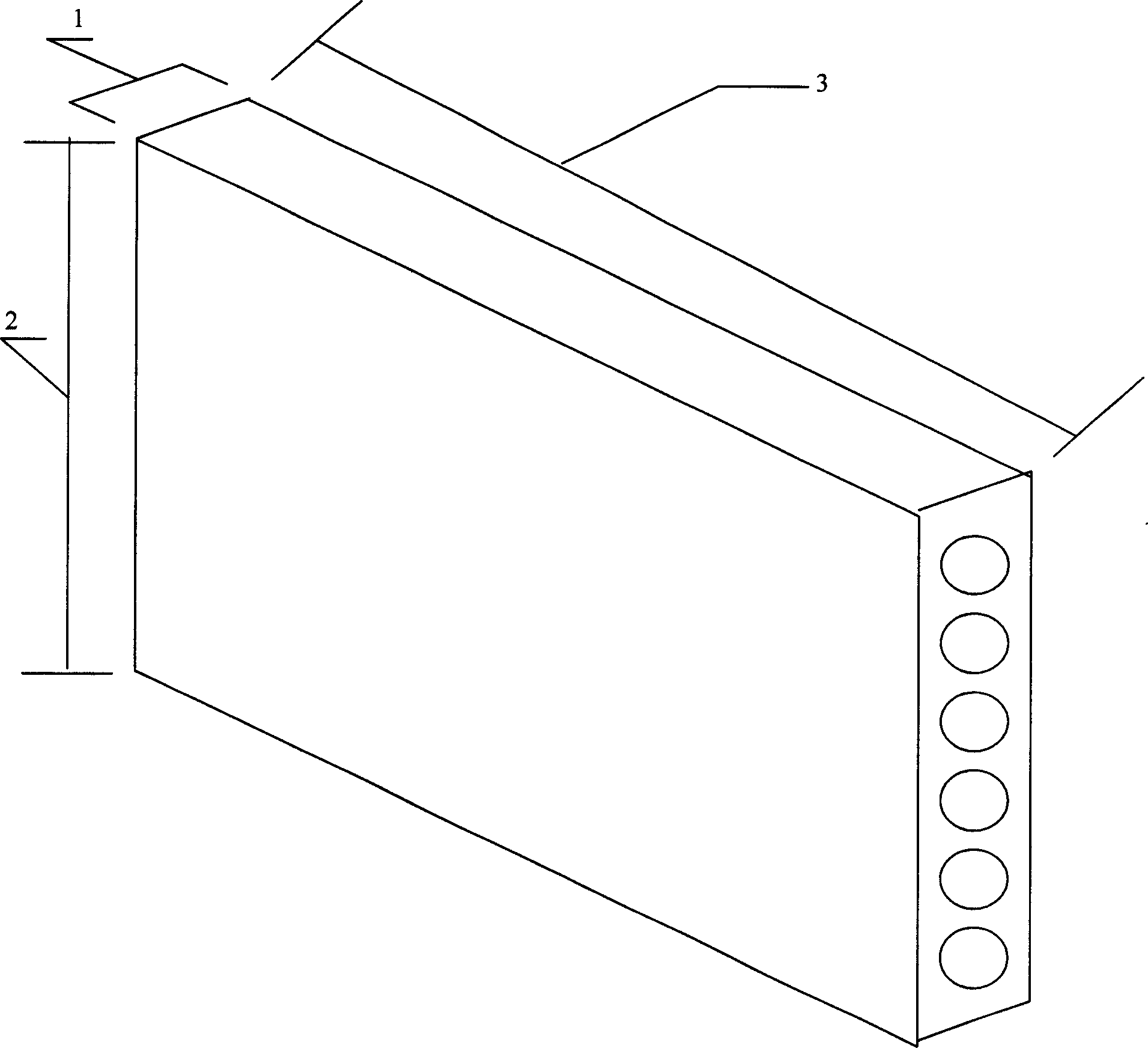

[0047] Production of recycled aggregate partition wall panels: partition wall panels are generally non-permanent partition walls constructed by decoration companies. The requirements for sound insulation, strength, and durability of the products are relatively low, and the requirements for the density of the products are not high. The specific method is 40% of recycled broken brick aggregate, 18-25% of magnesium oxychloride cement, 25-35% of plant fiber, 10% of fly ash, 2-5% of admixture, and the finished product is 600-1000*495*60- 90 specifications are mainly used, and the density level of the product is 600-800kg / m 3 class. This kind of wall panel is mainly used for the inner partition of the storage room, the decorative partition between the living room and the dining room with low sound insulation requirements, the partition of the kitchen and bathroom, and the pipe enclosure without sound insulation requirements, etc. The construction method is vertical horizontal mason...

Embodiment 3

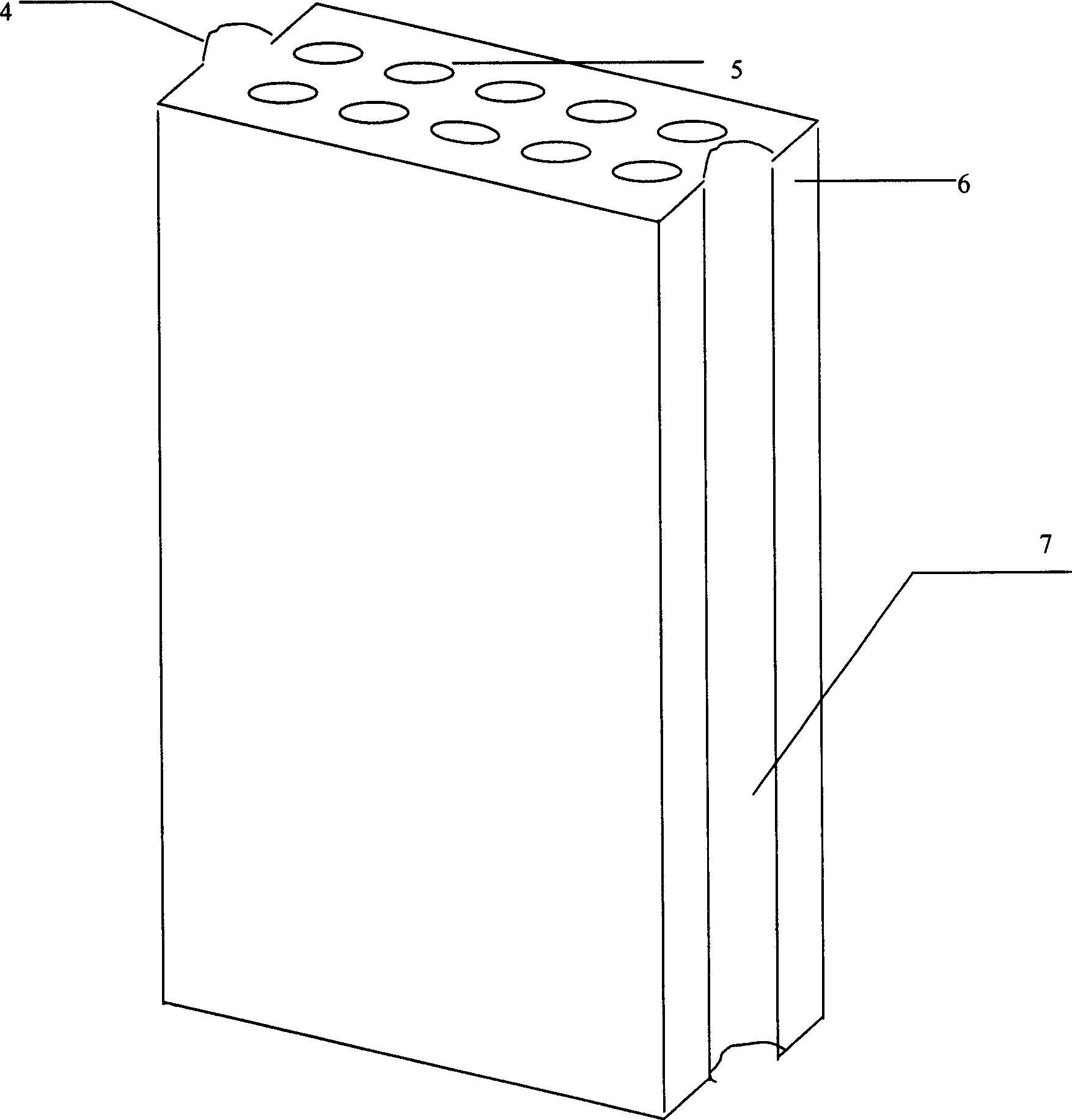

[0049] Production of exterior wall panels for house construction from recycled aggregates. Due to the anti-seepage and anti-freezing requirements of the external wall, the density of the external panels used for the external walls should be as high as possible, and the density of the internal panels of the external walls should be relatively low for thermal insulation. The specific production method of the outer wall and outer panel is 65-70% of recycled concrete aggregate, 18-25% of ordinary portland cement, inorganic cementitious material, 10% of fly ash, 2% of admixture, and the product is double row of holes 600-800* 495*120-190 specifications are the main ones.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density grade | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com