Minitype jet pump and preparation method

A jet pump and miniature technology, which is applied in the field of transmission, microfluid control, and microactuator, can solve the problems of difficult preparation process and complex micropump structure, and achieve the effect of simple structure, wide selection range and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

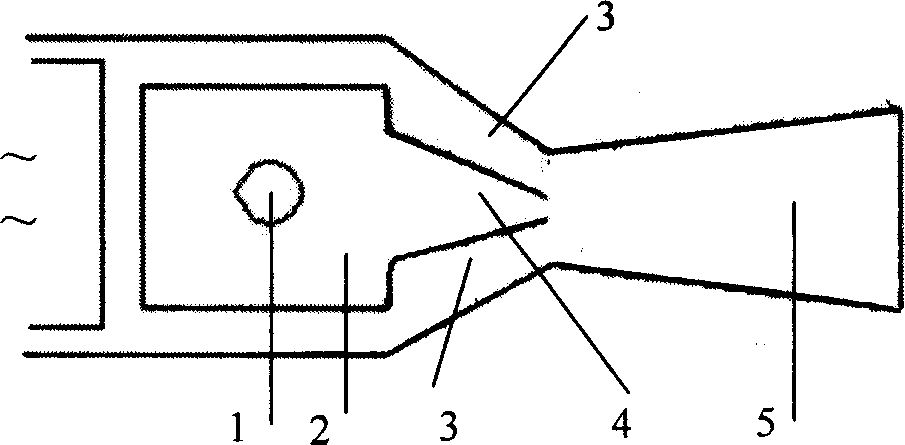

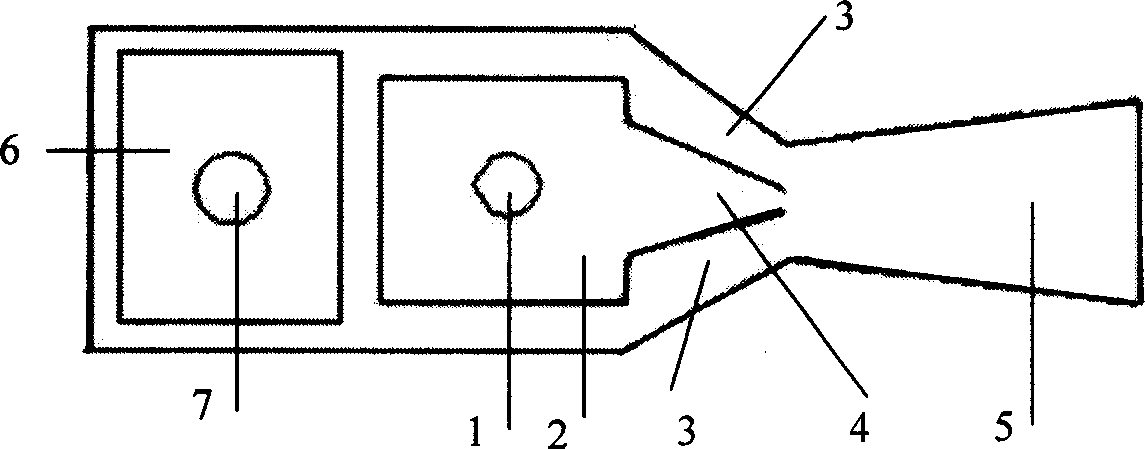

[0032] figure 1 It is a schematic plan view of the micro jet pump provided by the present invention. The main body of the micro-jet pump includes a driving structure and a suction structure. The driving structure is composed of a jet nozzle 4 and a driving chamber 2 connected thereto, wherein the driving chamber 2 is provided with a driving fluid inlet hole 1, and the driving fluid inlet hole 1 is located at A certain position corresponding to the upper part of the driving chamber 2 is an interface connected with an external pipeline, and the driving chamber 2 may be square, circular or oval. The driving chamber 2 and the jet nozzle 4 together constitute the driving structure for generating the jet. The present invention can also seal the driving cavity 2, process the pump cavity membrane by micromachining, stick a piezoelectric sheet, a magnetic sheet, a shape memory alloy film on it, or add a layer of membrane electrodes on the upper and lower surfaces of the pump cavity, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com