Side channel compressor

A compressor and side channel technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of complex and expensive manufacturing of shell and half shells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

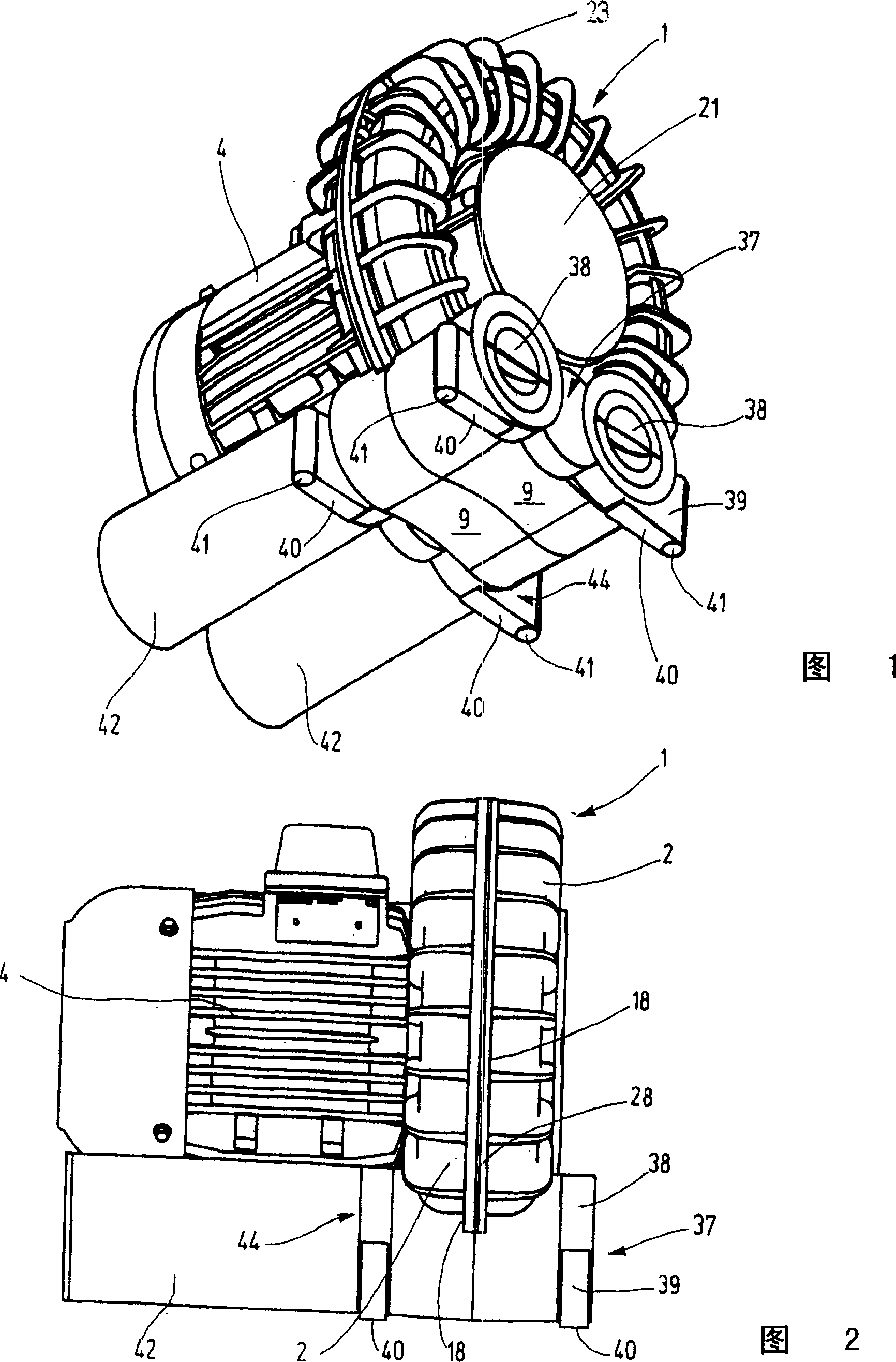

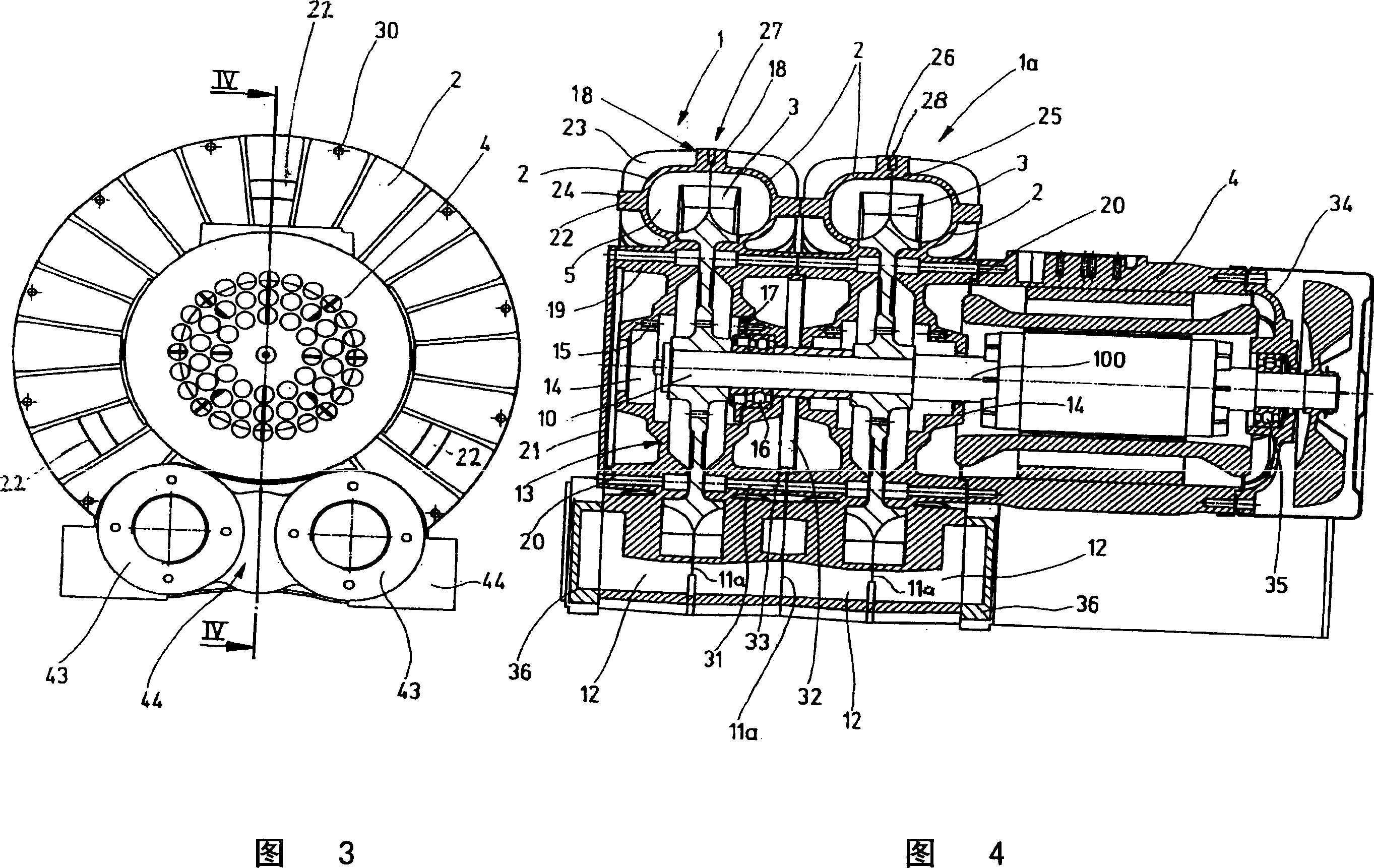

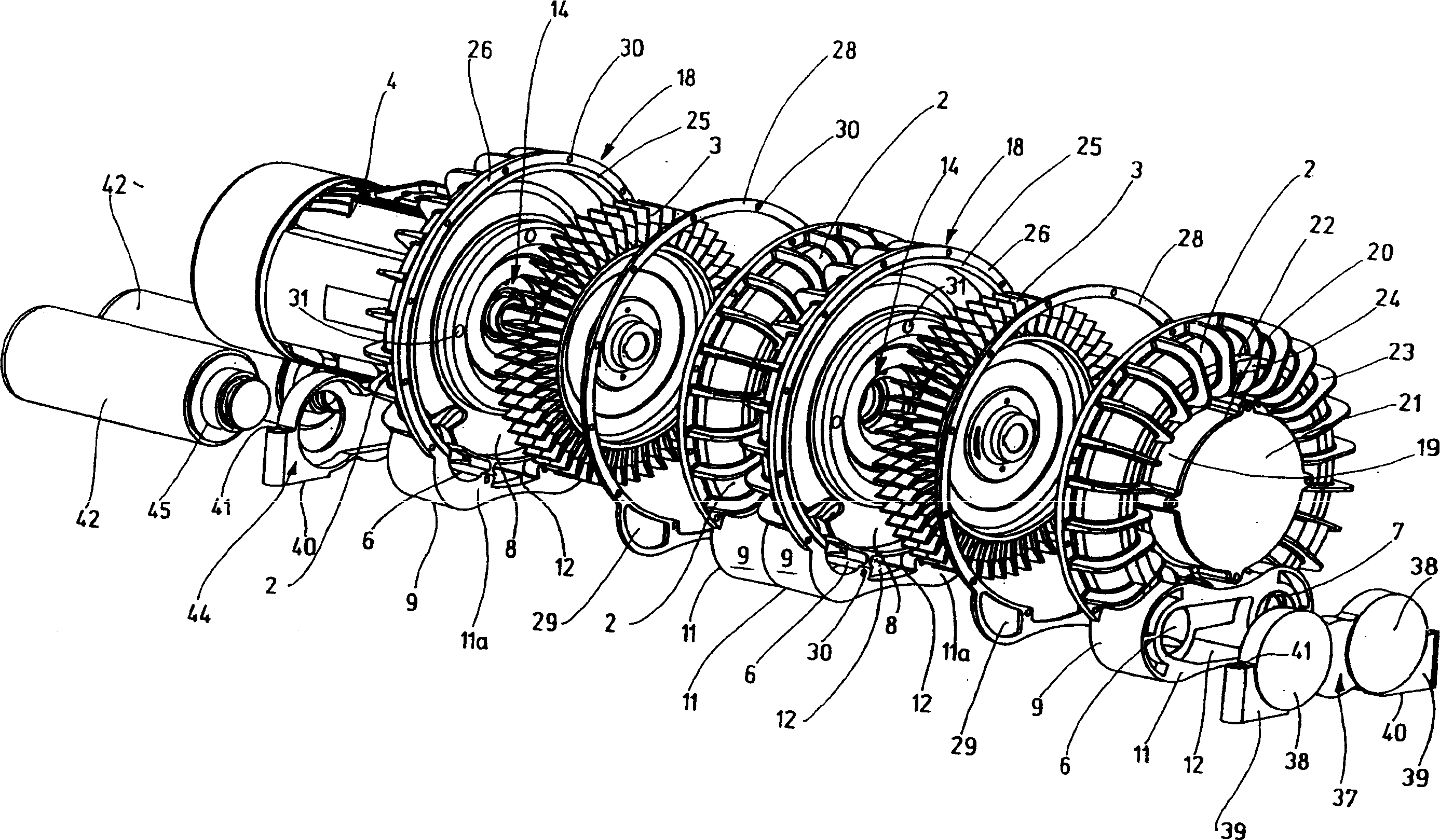

[0020] The side-channel compressor shown in FIGS. 1 and 2 has an essentially annular impeller housing 1 , which consists of two identical housing half-shells 2 and encloses an impeller, designated 3 in FIG. 4 . The impeller 3 is driven by an electric motor 4 which is coaxially flanged to the impeller housing 1 on one side. The two housing half-shells 2 forming the impeller housing 1 are identical. Each housing half-shell 2 has an impeller-accommodating side channel 5 which extends over a large part of the circumference and connects a shaped air intake duct 6 with a shaped air outlet duct 7 . Between the air intake line 6 and the air discharge line 7, a shut-off piece 8 is arranged, as is known per se for side-channel compressors. The air intake pipe 6 and the air discharge pipe 7 are in a common housing part 9 which is integrally formed on the housing half-shell 3 and has a flat mating surface 11 or 11 a extending perpendicularly to the impeller axis 10 on both sides. In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com