Float weighing sensor and PID deviation control method for dynamic coeighing

A weighing sensor and dynamic weighing technology, applied in the field of weighing sensors, can solve the problems of reducing reliability and response speed, increasing costs, and complicated circuit design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

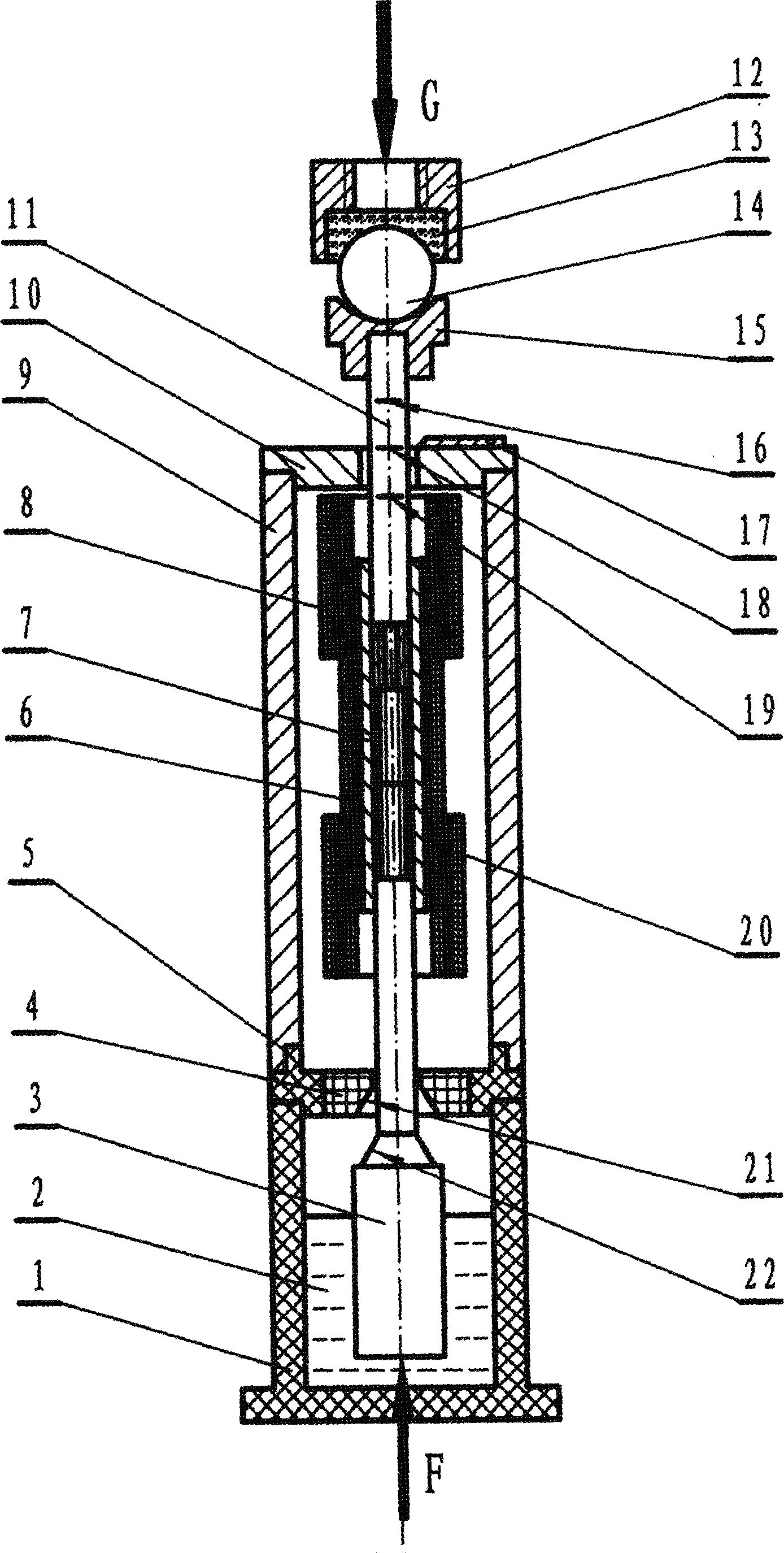

[0038] figure 1 Is the specific embodiment of the buoyancy load cell, in the figure:

[0039] Cylinder body (1), electromagnet shell (5), coil shell (9), cover (10) form the integral shell of buoyancy weighing sensor, and indicator needle (17) is fixed on the upper end face of cover (10).

[0040] Connecting piece (12), the permanent magnet (13) that is fixed on the central axis position of its lower end surface of the lower end of the connecting piece (12) with an inner arc surface, and a magnetic attraction made of magnetically permeable material with an inner arc surface on its upper end surface. The live hanging joint (15), the sphere (14) placed in the middle of the two corresponding solitary surfaces of the permanent magnet (13) and the magnetic suction live hanging joint (15), the displacement suspension fixed at the lower end of the magnetic suction live hanging joint (15) Rod (11) forms magnetic force centering suspension rod mechanism. The connecting piece (12) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com