Full paper pallet box

A paper pallet and box body technology, applied in the field of all-paper pallets, can solve the problems that the strength and rigidity cannot meet the requirements, the honeycomb cardboard packaging box is incompetent, and the direction of the forklift is limited, so as to improve the overall mechanical performance and reduce storage. Space, convenient packaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

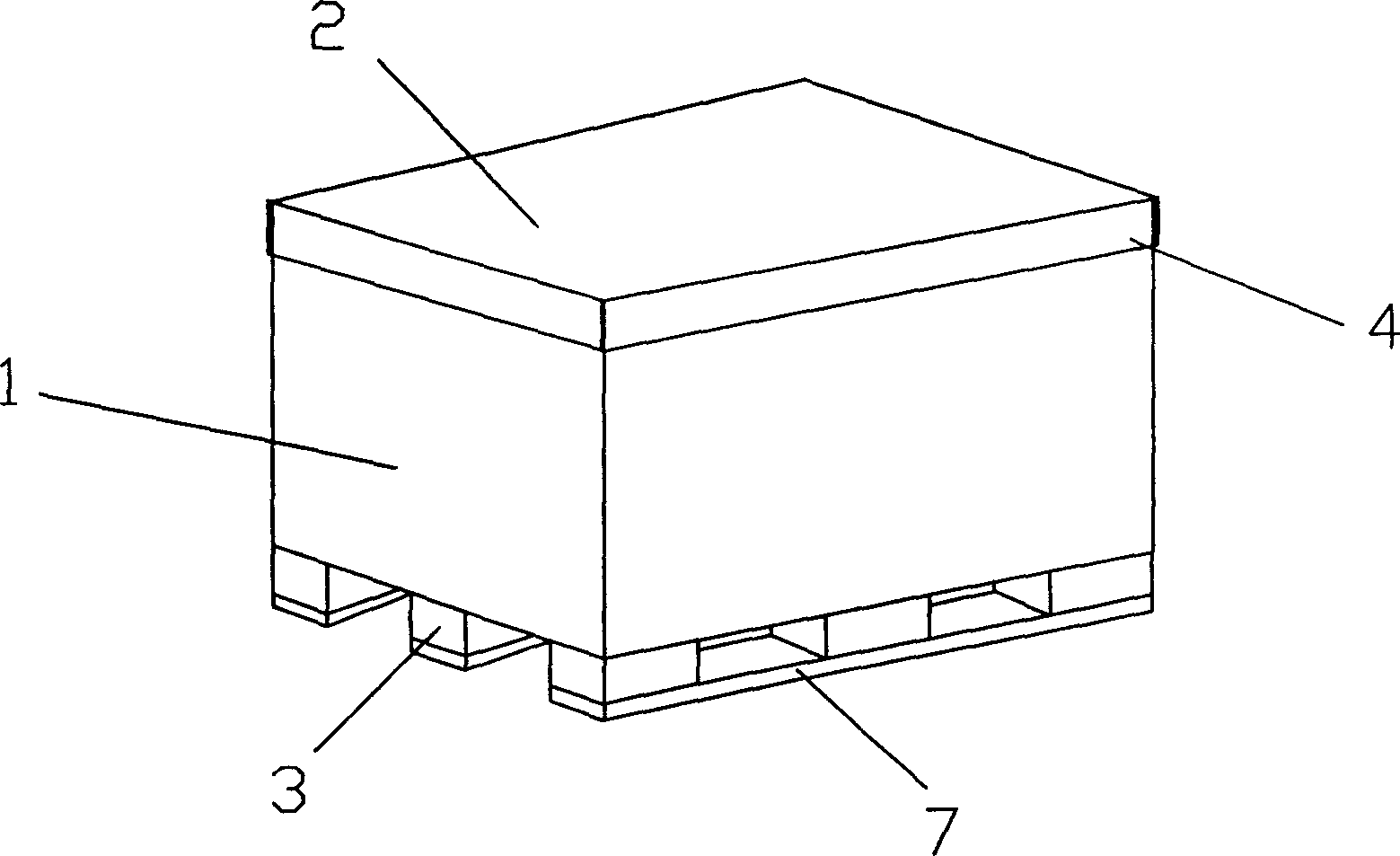

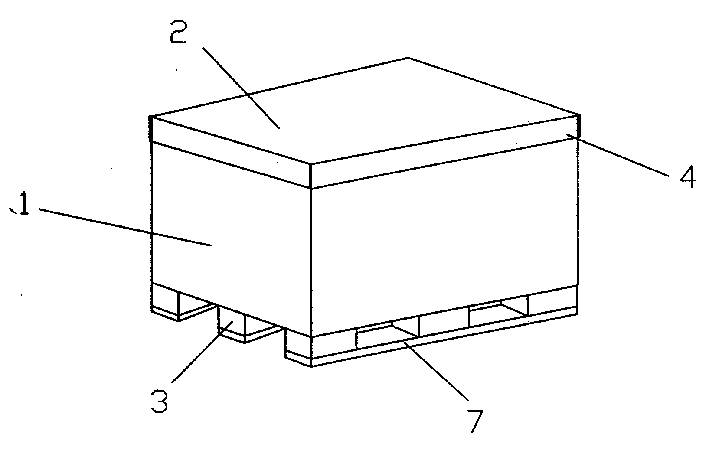

[0011] exist figure 1 The supporting box shown in includes box body (1), box cover (2) and box foot (3).

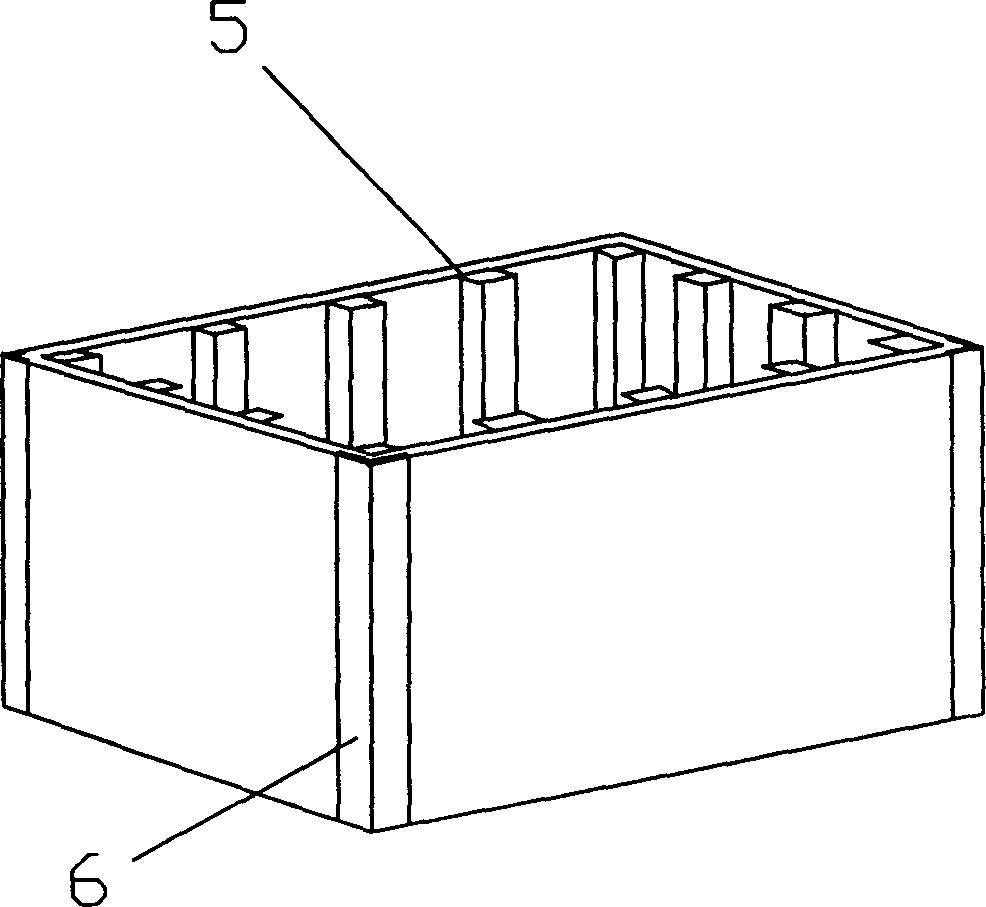

[0012] The box body (1) is composed of four box wall panels and box bottom panels. The box wall panels are made of honeycomb cardboard or corrugated cardboard or composite cardboard with a thickness of 20mm. and paste the reinforcing ribs (5). The bottom plate of the box is made of honeycomb cardboard or composite cardboard with a thickness of 20-50 mm. First, the material is cut, and then the composite cardboard strips or pads are inserted, kraft paper is wrapped, and then the four box wall panels and the box bottom are combined and bonded to form a box body. The reinforcing rib (5) adopts paper-made tubes such as square, rectangular, and triangular arc-shaped tubes, and the paper rectangular tubes are formed by bonding kraft paper and adhesive glue. The outer or inner four corners of the box body (1) are bonded with paper corners (6), and then pasted with kraft paper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com