Low noise high pressure centrifugal fan

A high-pressure centrifugal fan and low-noise technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of lack of small flow, huge processing costs, high-frequency noise, etc., and achieve a wide selection of materials and unique shapes , Noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

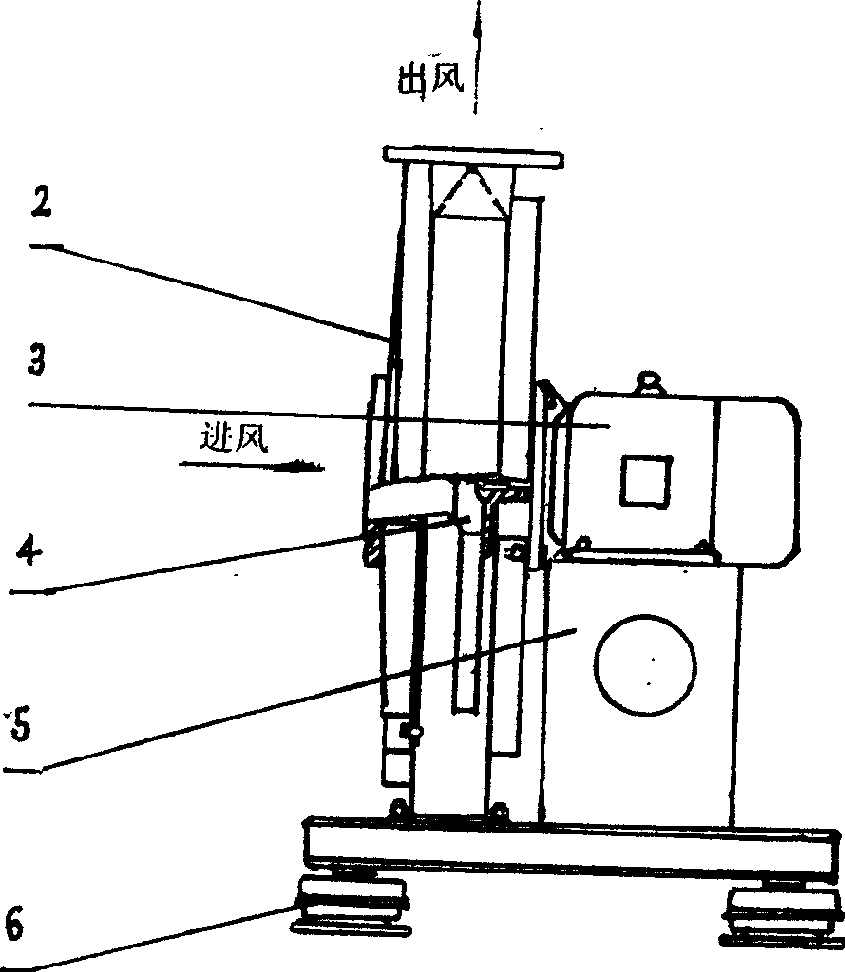

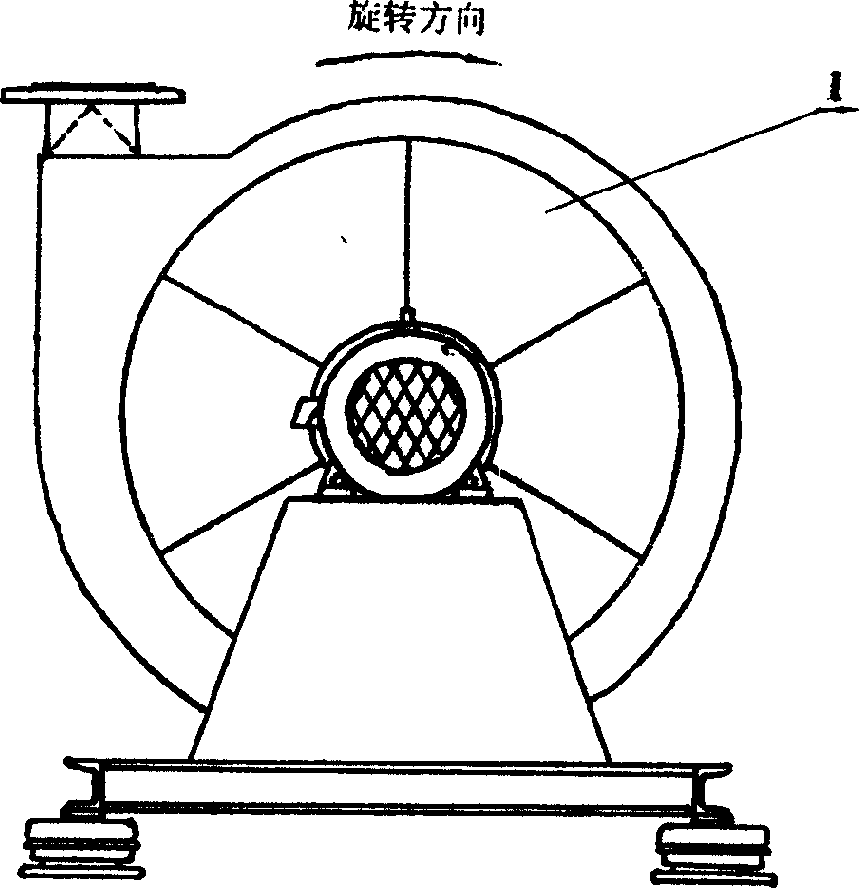

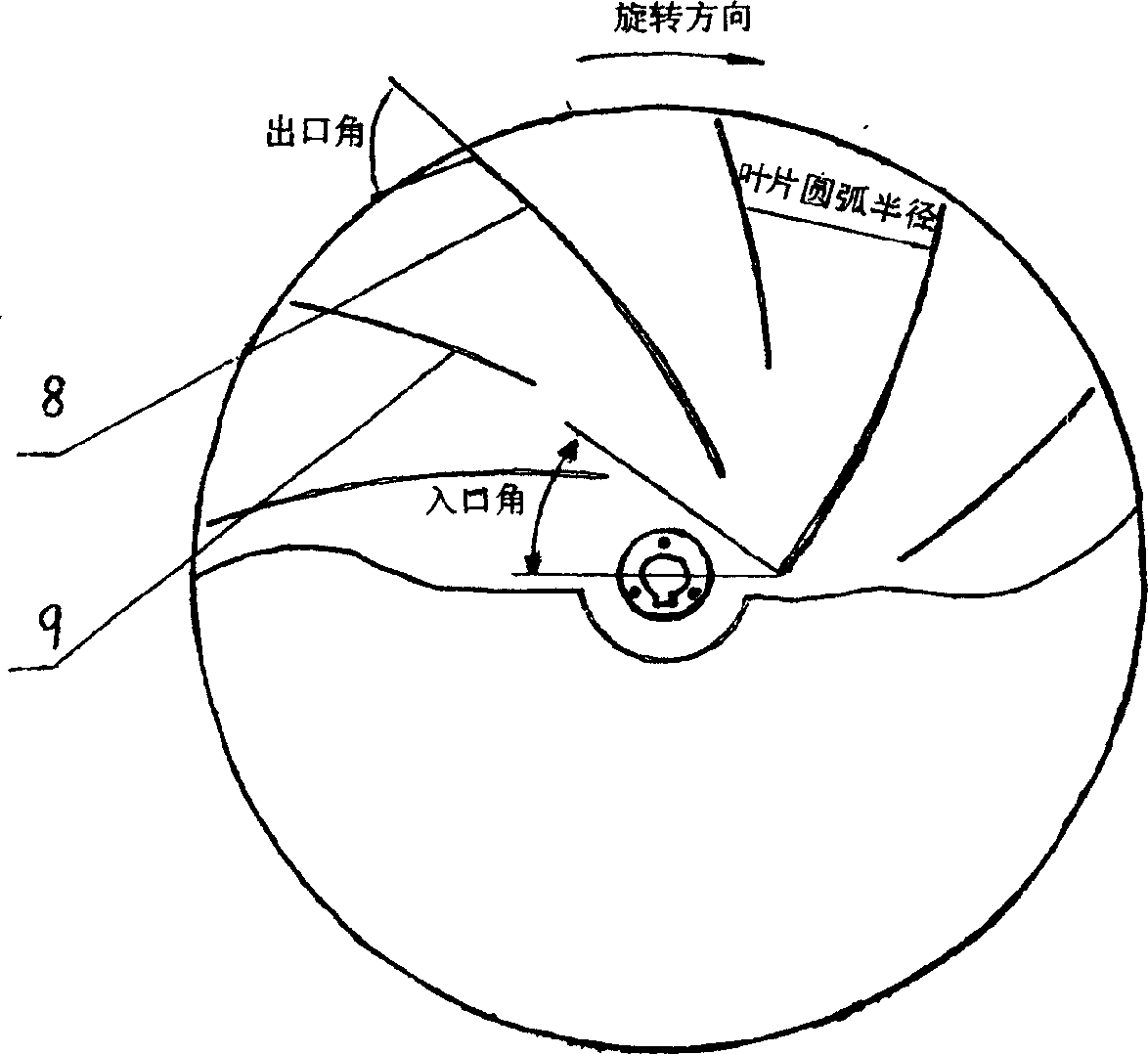

[0016] Embodiment 1: a low-noise high-pressure centrifugal fan, which includes a casing 1, an air inlet cover 2, a motor 3, an impeller 4, and a frame 5, and the motor 3 drives the impeller 4 to rotate clockwise or counterclockwise in the casing 1, The airflow is inhaled from the inlet of the air inlet cover plate 2, and the airflow flows out from the air outlet due to the suction and rejection of the impeller 4 and the regulation and guidance of the casing 1. Device 6 carries the whole machine in contact with the ground, and plays a role in attenuating the vibration of the fan, see the attached photo figure 1 and 2 . The wheel cover 6 and the wheel disc 7 in the impeller 4 form an air inlet and regulate the air flow, the wheel disc 7 is connected with the shaft disc 10, the long blades 8 and the short blades 9 are located between the wheel cover 6 and the wheel disc 7 and will Its connection, the wheel cover 6 acts as an air intake and regulates the airflow with the wheel d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com