Method for processing camphorwood product

A processing method and technology of camphor, applied in wood processing equipment, manufacturing tools, wood treatment, etc., can solve the problems affecting the appearance, color, insect repellent effect and loss of camphor, so as to prevent the loss of camphor, low cost, Preserve the effect of appearance

Inactive Publication Date: 2005-03-02

陈一鸣

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This will cause a large amount of camphor, the active ingredient in camphor, to be lost, which will greatly affect the appearance, color and insect repellent effect of camphor.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0011] Take 1000g of camphor wood, choose 500g of the better material to wash, then dry at 55°C, then peel, slice, crush, and then press into pellets or flakes, and finally can be made into unused camphor according to the purpose. wooden product.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

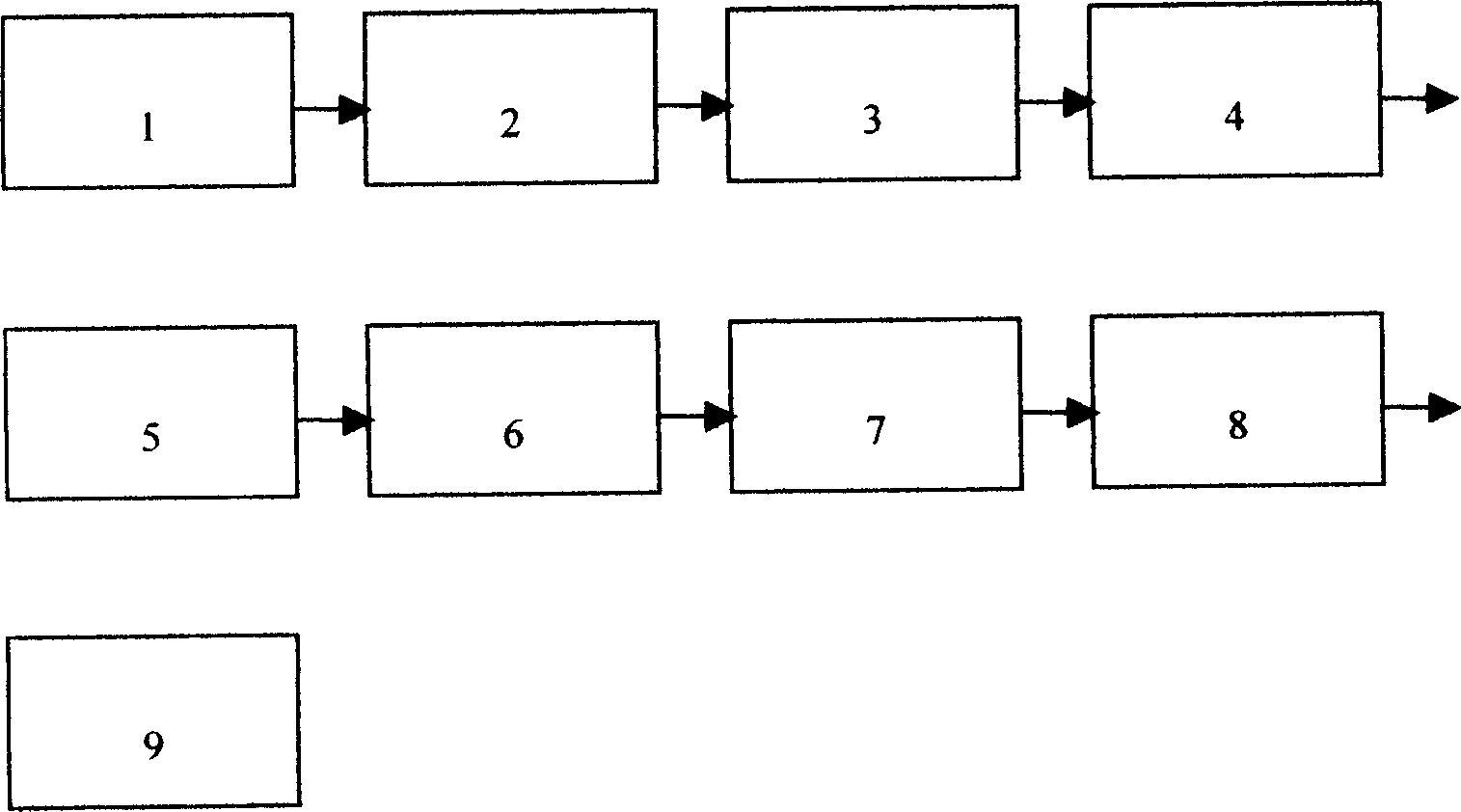

The present invention relates to timber processing, and especially camphor wood product processing method. The present invention features that the camphor wood product processing includes the following technological steps: selecting timber, washing, drying, barking, sheeting, crushing, compounding and pressing to form. Compared with available technology, the said process can avoid the loss of camphor as the effective component to result in excellent pest repelling effect.

Description

[technical field] [0001] The invention relates to the field of wood processing, in particular to a processing method of camphor wood products. [Background technique] [0002] Traditional camphor wood processing methods are generally relatively simple and extensive, just simple cutting and peeling. This will cause a large amount of camphor, the active ingredient in the camphor wood, to be lost, which will greatly affect the appearance, color and insect repellent effect of the camphor wood. [Content of the invention] [0003] The object of the present invention is to provide a kind of processing method of the camphorwood product that processing technology is simple, and can effectively prevent camphor loss. [0004] To achieve the above object, the present invention is achieved by the above method: a processing method of camphor wood products, characterized in that comprising the following process steps: (1) material selection (2) washing material (3) drying (4) peeling ( ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B27K5/00B27M1/08

Inventor 陈一鸣

Owner 陈一鸣

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com