Ear picking cutting table for non-rowed corn combine

A combine harvester and header technology, which is applied in the fields of harvesters, agricultural machinery and implements, applications, etc., can solve the problems of small adaptability of corn harvesting machinery, low work efficiency, difficulty in row harvesting, etc., so as to facilitate daily maintenance, improve Efficiency, the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

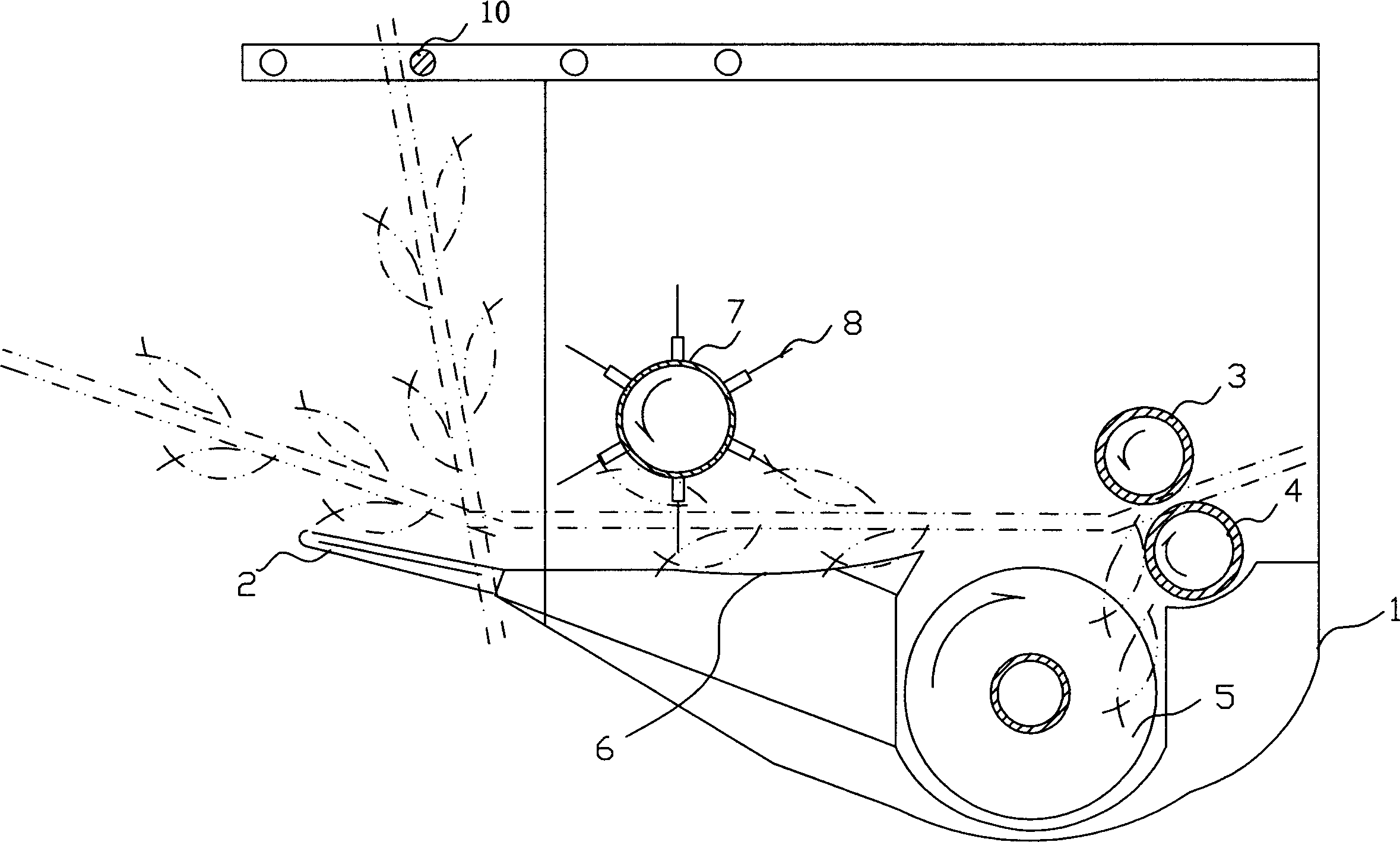

[0016] Such as figure 1 As shown, the fringe harvesting platform of the present invention includes a platform 1, a reciprocating structure cutter 2 arranged at the front end of the platform 1, and a pair of adjustable pair of rollers 3 arranged at the rear end of the platform 1 , 4 composed of the fringe picking mechanism, and the ear conveyor 5 of the auger type structure arranged between the reciprocating structure cutter 2 and the pair of rollers 3, 4, the rear end of the reciprocating structure cutter 2 is provided with a grain feeding bottom plate 6. A grain-feeding roller 7 is arranged horizontally above the grain-feeding bottom plate 6 along its transverse direction, and an elastic dial 8 is arranged radially on the peripheral surface of the grain-feeding roller 7 . On the stand 1 above the front and back of the reciprocating structure cutter 2, an adjustable pusher bar 10 is provided.

Embodiment 2

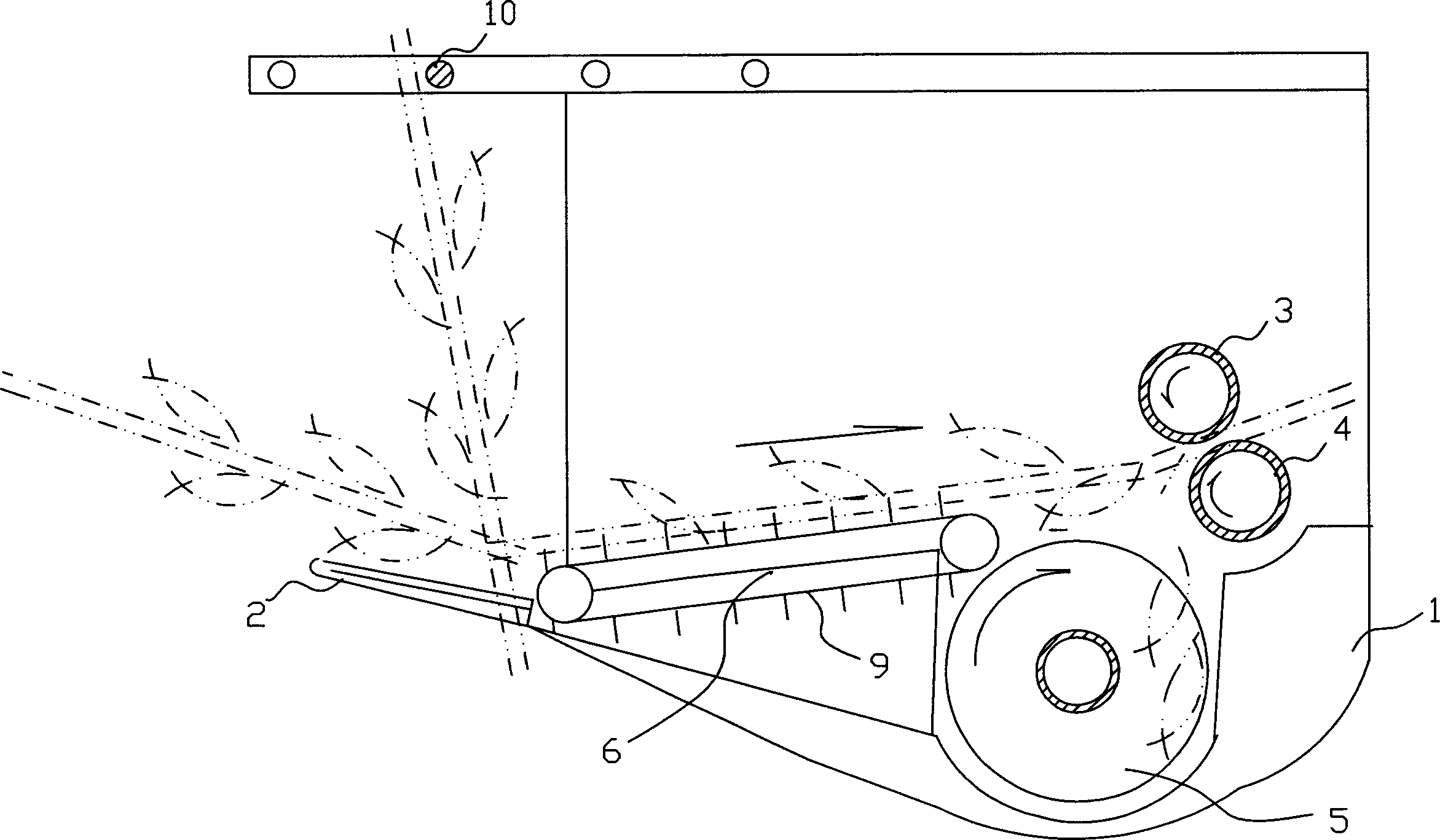

[0018] Such as figure 2 As shown, the fringe harvesting platform of the present invention includes a platform 1, a reciprocating structure cutter 2 arranged at the front end of the platform 1, and a pair of adjustable pair of rollers 3 arranged at the rear end of the platform 1 , 4 composed of the fringe picking mechanism, and the ear conveyor 5 of the auger type structure arranged between the reciprocating structure cutter 2 and the pair of rollers 3, 4, the rear end of the reciprocating structure cutter 2 is provided with a grain feeding bottom plate 6. Between the cutter 2 and the pair of rollers 3 and 4, a rotary chain rake 9 is arranged longitudinally along the grain feeding bottom plate 6; on the platform 1 above the front and upper side of the reciprocating structure cutter 2, there is a front and rear adjustable push rod 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com