Ridge planting carrot harvester achieving radian-free turning during work and use method

A technology for carrots and harvesters, which is applied to digging harvesters, harvesters, and rigid working parts, etc., can solve time-consuming problems and achieve the effects of saving time for turning around and changing lines, improving efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

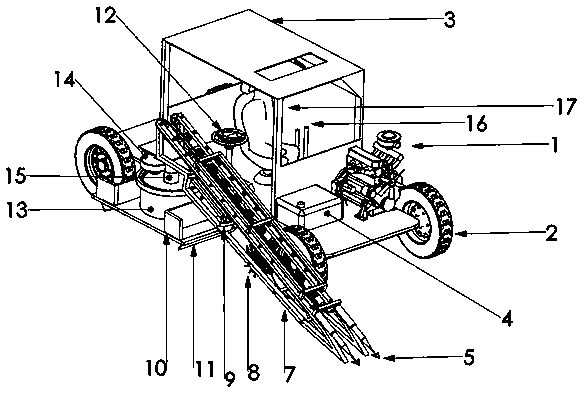

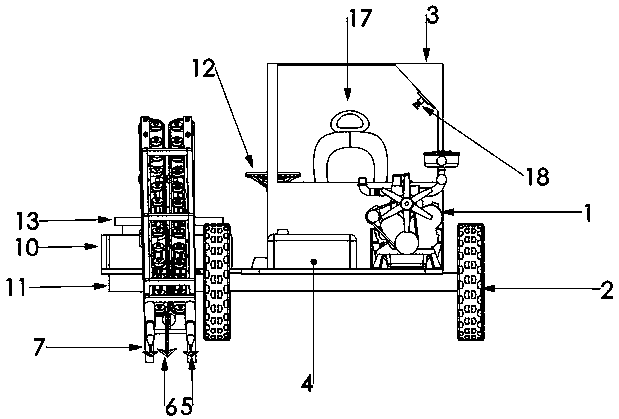

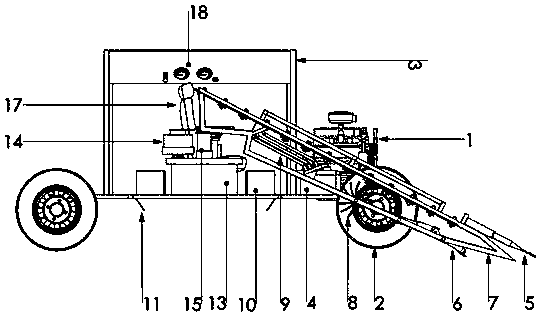

[0027] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0028] like Figure 1~5 A ridge-growing carrot harvester free from arc turning during work is shown, including a frame 3, and a harvesting frame 7, a power unit, a cab and a walking device installed on the frame. The harvesting frame is tilted backward and upward, and a clamping and conveying device is installed on the harvesting frame. In this embodiment, the walking direction of the harvester during operation is the front.

[0029] This embodiment also includes a slewing bearing 13 with the outer ring and the frame affixed. The inner side of the outer ring is provided with teeth distributed along the circumferential direction. Then, the rotary shaft 15 is concentrically matched with the shaft hole on the rotary support 13, and the harvesting frame is also fixed with a rotary drive hydraulic motor 14, and the output shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com