Green tea natural fibre, textile and manufacturing method thereof

A technology of natural fibers, production methods, used in fiber processing, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

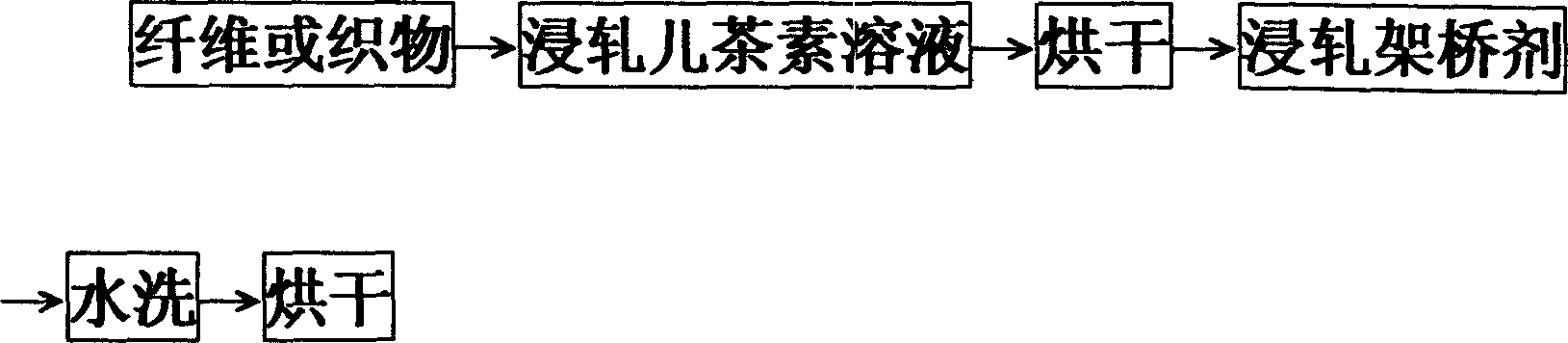

[0010] Embodiment 1: green tea fiber production

[0011] Cotton fiber is dipped into catechin solution, and catechin solution is made of catechin 2.5%, puffing agent P-46 1%, penetrating agent JFC 0.5% and water 96% by weight, at a temperature of 75 ℃, pressure 0.20MP and padding for 35 minutes to make the moisture content 65%, remove it and place it in a drying container, preheat it at 98℃ for 5 minutes, then bake it at 120℃ for 3 minutes, then put it in The bridging agent is impregnated in the rolling groove, and the bridging agent is made of ethylene sulfoxide 1% by weight, penetrating agent JFC 0.5% and water 98.5%, and the temperature is 90°C and the pressure is 0.20MP. Padding for 55 minutes, Make it have a moisture content of 65%, then wash it in cold water at 25°C for 4 times (passes), then soap it at 95°C for 10 minutes, put it in a drying container, and dry it at 100°C (with a moisture content less than 0.5%).

Embodiment 2

[0012] Example 2: Production of Green Tea Fabric

[0013] Immerse the cotton fabric into the catechin solution made of 4% catechin by weight, 1% swelling agent S-2P, 0.5% penetrant T and 94.5% water, at a temperature of 70°C and a pressure of 0.25MP, Roll for 40 minutes to make its moisture content 75%, put it into a drying container, pre-bake it at 100°C for 3 minutes, then bake it at 120°C for 3 minutes and dry it (moisture content is less than 0.2%). The bridging agent made of ethylene sulfoxide 1.5% by weight, penetrant T 0.5% and water 98% is soaked for 50 minutes at a temperature of 95°C and a pressure of 0.25MP, and the water content is 65%. Rinse 4 times with cold water at 20°C, then soap at 95°C for 10 minutes, then place in a drying container and dry at 100°C.

[0014] The difference between the present invention and current green tea products (such as products from various factories in Japan) is that catechins are connected with cotton cellulose through chemical bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com