Foamed-material composite tray and reutilizing method for waste foamed material

A foamed material and tray technology, which is used in the field of reprocessing waste foamed materials to make tray materials, can solve problems such as undocumented, easy water, and re-pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

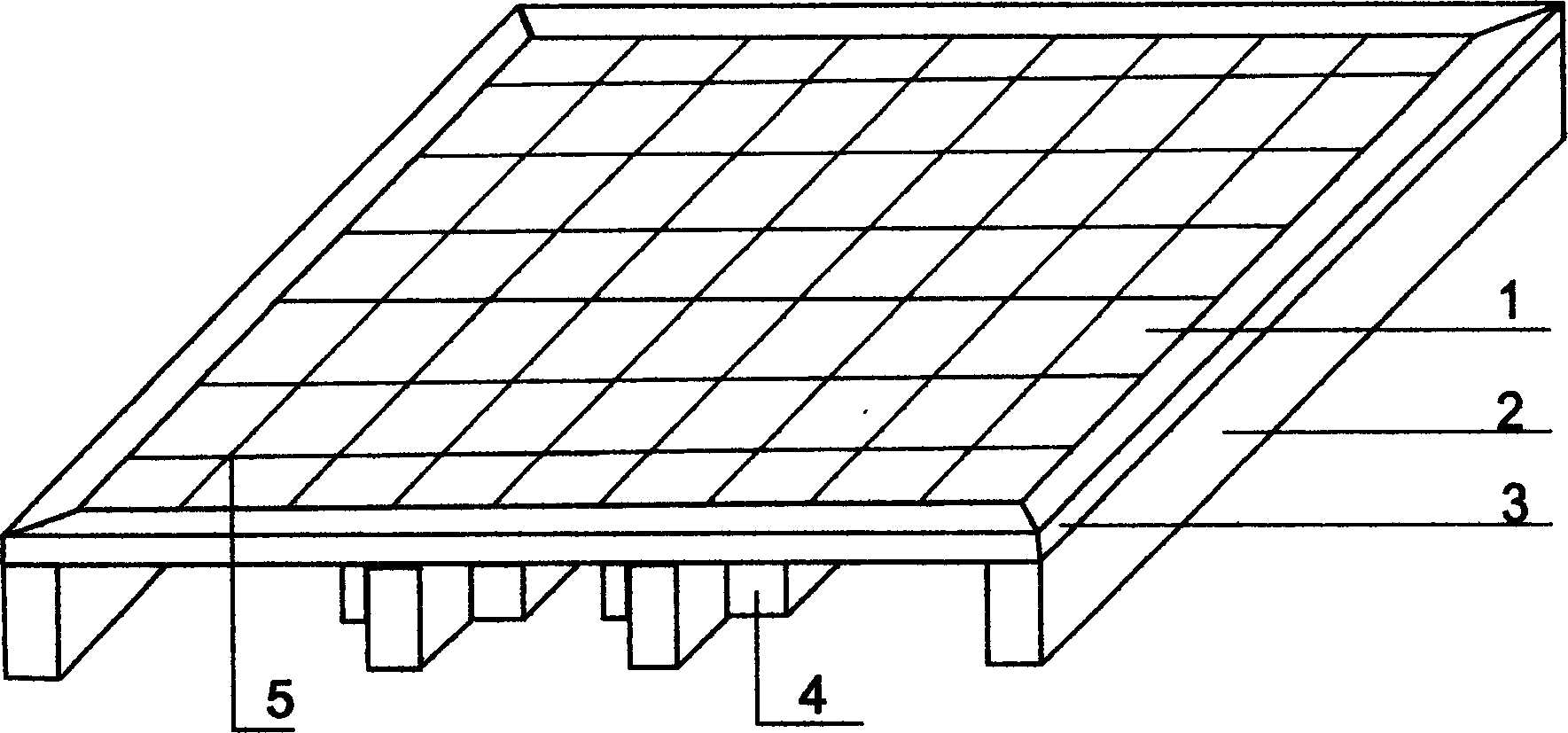

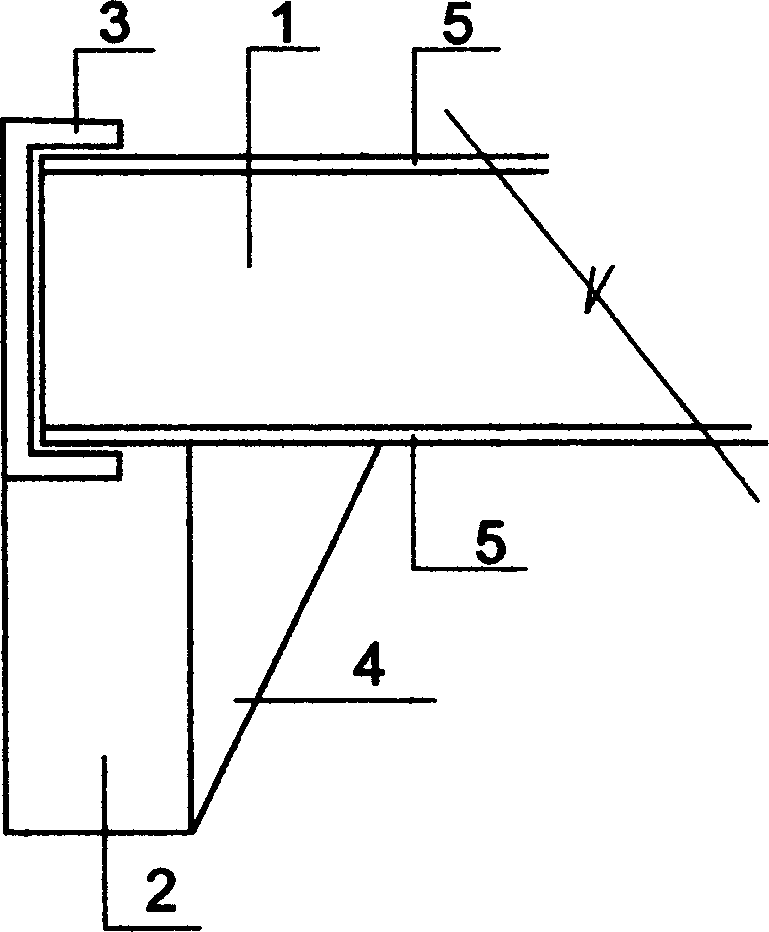

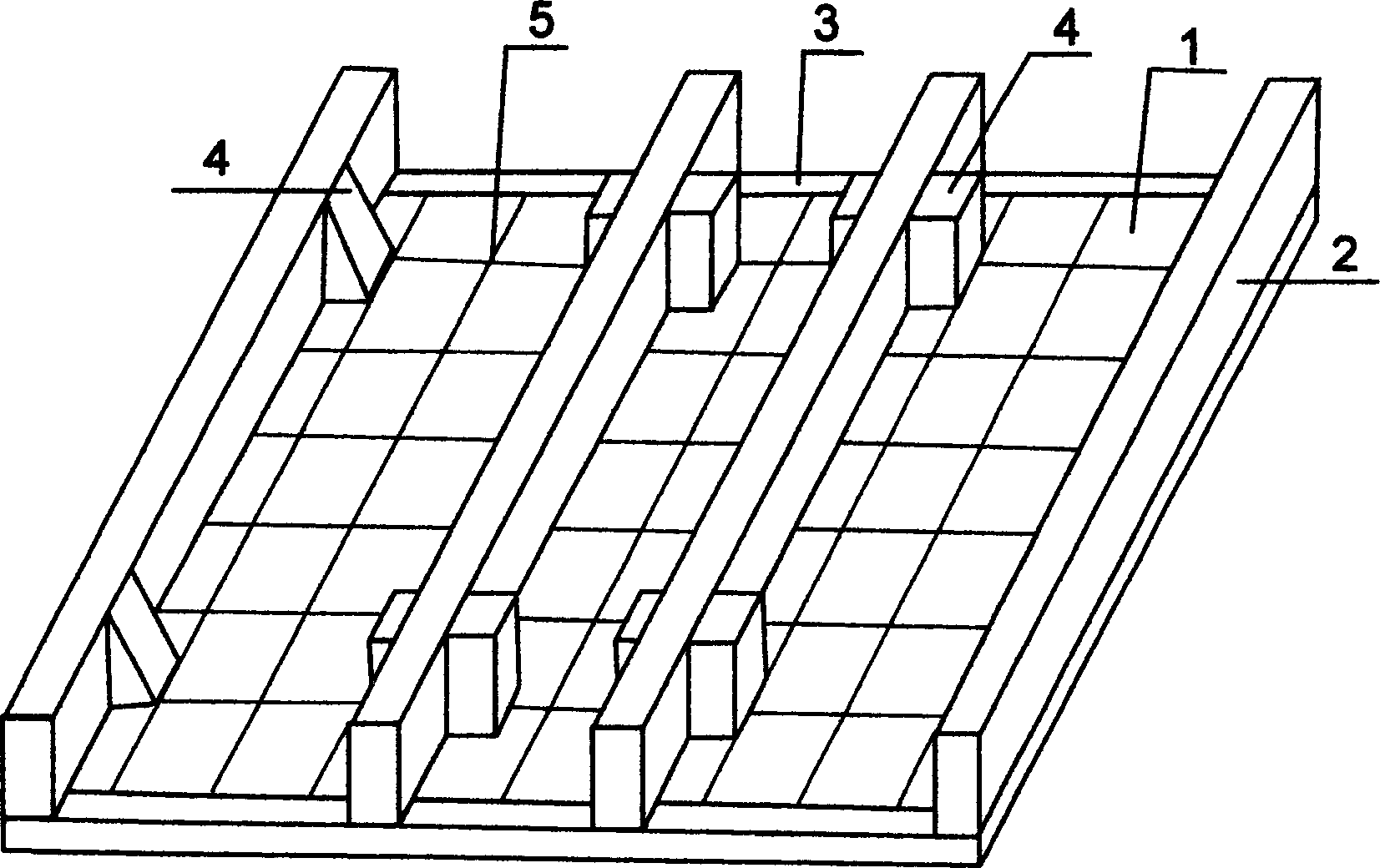

[0029] The figure shows that the bearing plate surface ① can be large or small according to requirements, and the protective net or strip ⑤ is attached to the upper and lower parts of the bearing plate surface ①, while the bearing plate surface ① is inlaid with U-shaped decorative grooves ③ on four sides. And it can be located at the contact point of the protective net or strip, and welded by electric welding to form a combined bearing flat surface with increased bearing capacity, and the support column ② can be bonded to form a pallet structure at the bottom of the combined bearing flat surface, and support The column attachment ④ can be located on the support column ② and can be bonded to form a support column as a whole.

[0030] Through the above description of the technical features of the present invention, it can be seen that a complete and strong new tray has been formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com