Process for machining ends, positioning ports and holes of central opened pump by special boring apparatus

A process method and end face technology, applied in boring/drilling, metal processing equipment, drilling/drilling equipment, etc., can solve the problem of inflexible operation of rotor parts, poor product quality and quantity, and coaxial holes of each hole. To solve problems such as large accuracy error, to achieve the effect of speeding up the time of product launch, improving product quality, and flexible rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

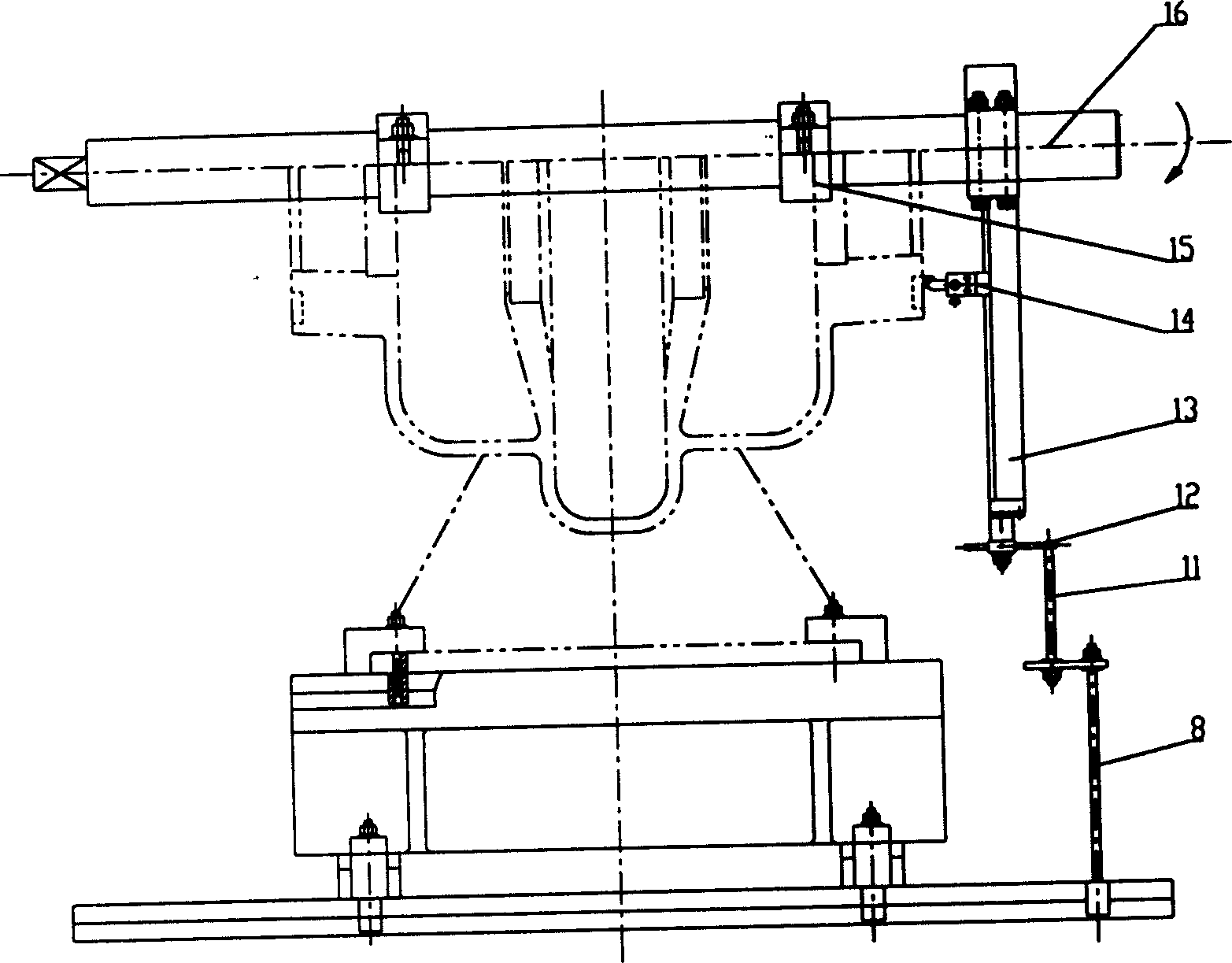

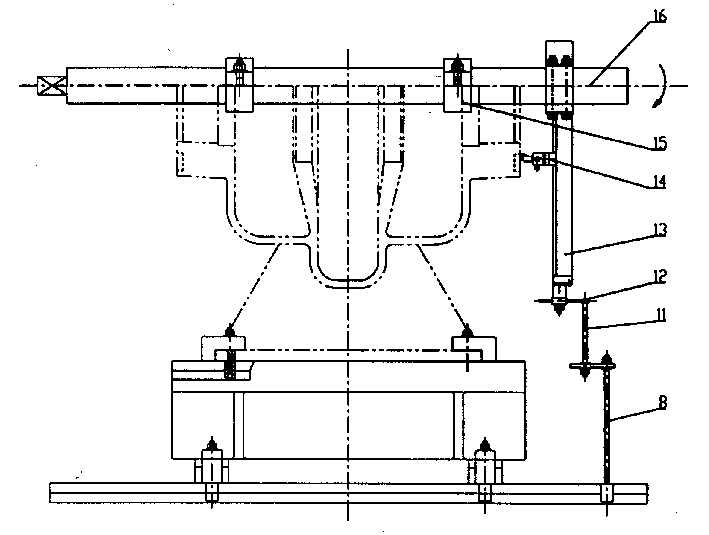

[0012] Example 1: See attached figure 1 The method of opening the end face of the pump and positioning the stop using a special boring machine.

[0013] The support frame of the boring device 15 is fastened to the screw hole on the right side of the open face of the pump body. The power drives the boring bar 16 through the universal joint and drives the knife mechanism to rotate. The dial 12 on the knife mechanism 13 rotates to When it hits the lever 11, turn the dial 1 / 5 circle, and the dial is divided into 5 equal parts, driving the screw on the knife mechanism 13 to rotate 1 / 5 circle, and the screw drives the nut under the tool holder 14 Move 1 / 5 of the pitch forward to complete a tool pass; the tool feed mechanism continuously rotates, and the tool on the tool holder continuously cuts forward to complete the rough and fine processing of the end face of the pump body; the positioning stop is processed in the same way; the tool travel mechanism 13 and the support rod 8, the shi...

Embodiment 2

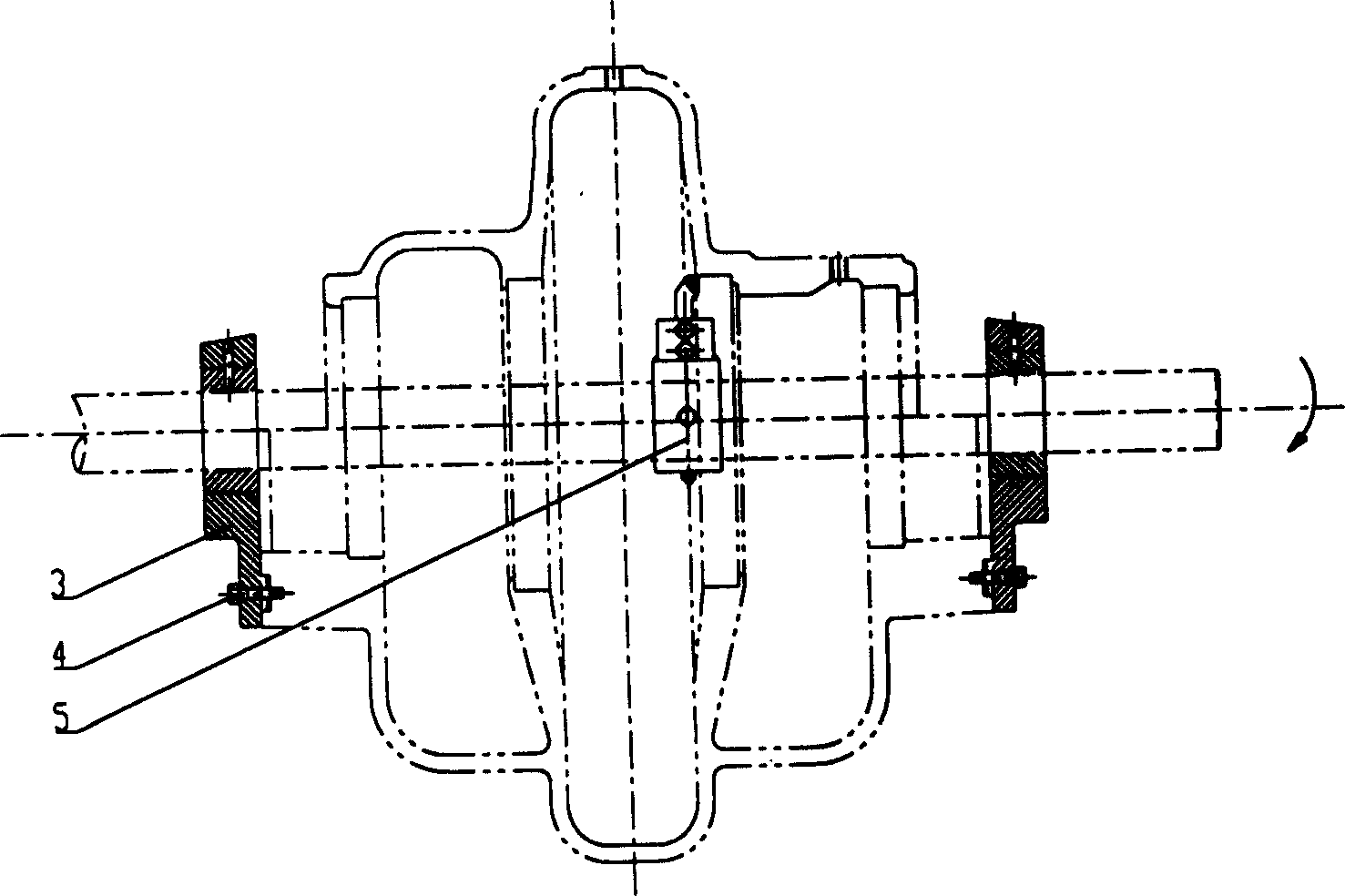

[0014] Example 2: See attached figure 2 , Use boring special machine to process the pump hole system.

[0015] Taking the finished pump body's end faces and positioning stop as the reference, the bearing body 3 is fastened to the corresponding end face and positioning stop of the pump body with bolts 4; when the boring bar rotates, the boring tool holder 5 fixed on the boring bar is driven Rotate, the tool on the boring tool holder 5 cuts the holes on the pump body and pump cover until all the holes are processed. When measuring the hole diameter of the pump body and pump cover, open the pump cover and close the pump cover with positioning pins after the measurement is completed. After the positioning pins are tightened, tighten them and continue processing until the requirements are met . The boring tool holder 5 can be used to boring the hole system on the pump body and the pump cover. The jump of the two end faces of the pump body and the positioning stop is less than 0.05.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com