Luminous Christmas tree

A Christmas tree and light-emitting technology, applied in light guides, optics, optical components, etc., can solve the problems of unfavorable overall shape, fast brightness decay, and difficulty in changing multiple colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

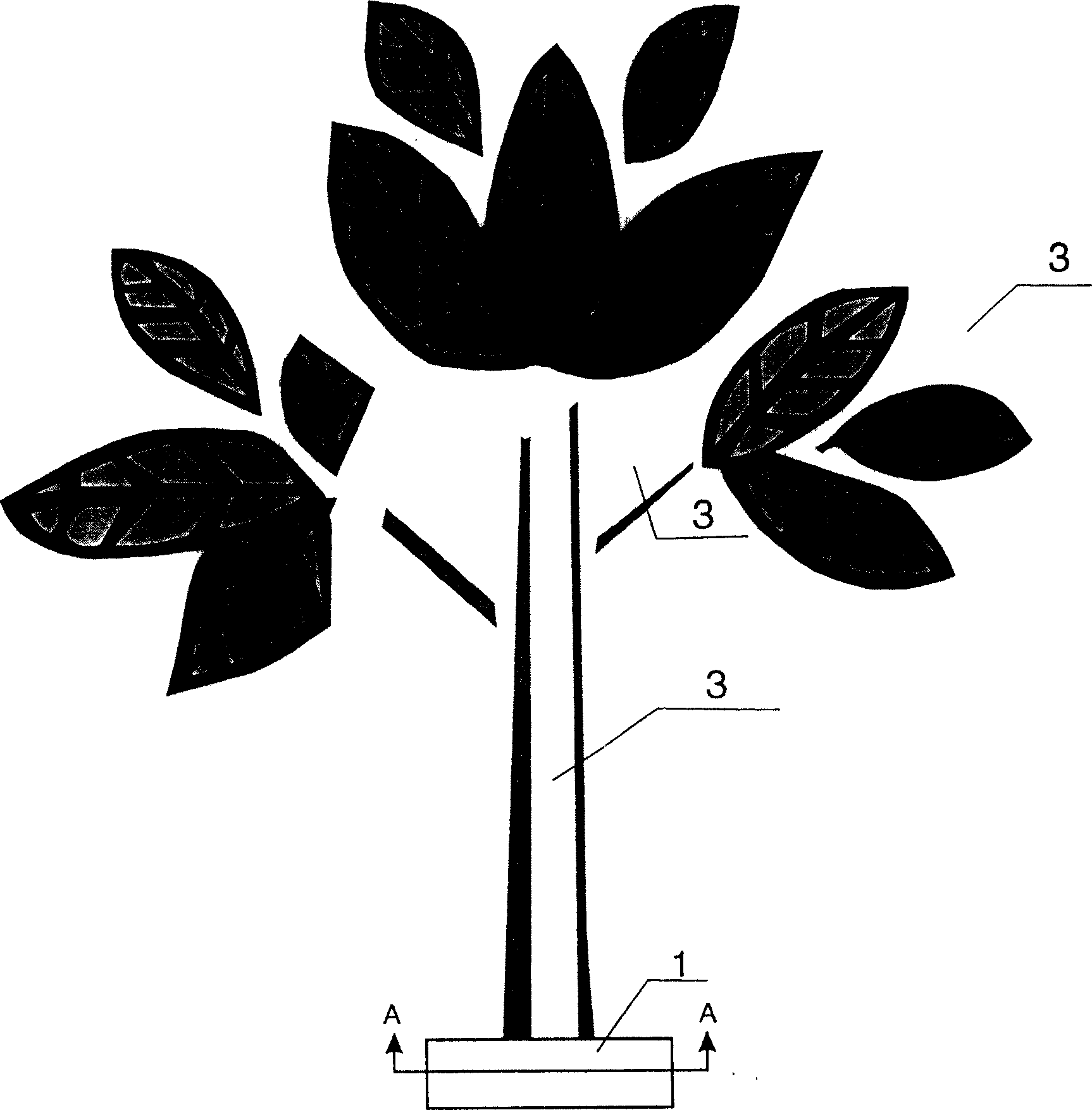

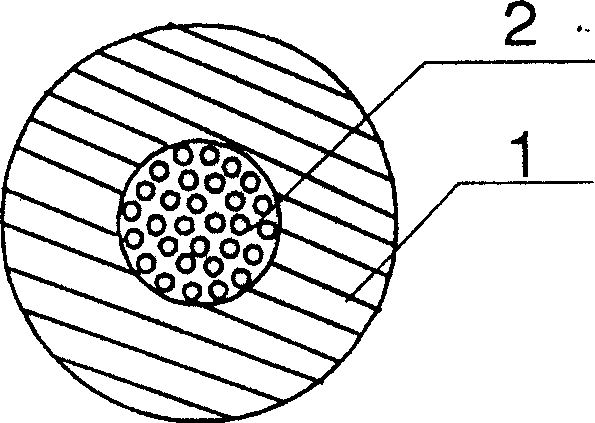

[0016] A "light-emitting Christmas tree", the basic structure includes a tree base 1, a light source in the tree base - light-emitting diode array 2, a trunk, branches, and leaves made of plastic optical fiber materials as a whole, and a trunk made of plastic optical fiber materials as a whole The surface of branches, branches and leaves is evenly sprayed with a layer of lighting material layer 4, and an external (or built-in) power supply 5 is formed.

[0017] In one example, the whole trunk, branches, and leaves are made of plastic optical fiber material, and the surface of the plastic optical fiber material is sprayed with lighting material. , refraction, and diffraction complex optical principles, the surface of the whole tree forms a surface light source. The whole tree glows.

[0018] In one example, the whole trunk, branches, and leaves can be made hollow, which can reduce the cost, and the effect can be all. Similarly, the Christmas tree becomes luminous.

[0019] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com