Motor iron core, motor and method for manufacturing motor ironcore

A technology for electric motors and iron cores, which is applied in the manufacture of stator/rotor bodies, magnetic circuit shapes/styles/structures, and magnetic circuit static parts, etc. problem, achieve the effect of reducing cogging torque and torque ripple, preventing the decline of magnetic properties, and improving the bending precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] (first embodiment)

[0034] The following is based on Figure 1-7 A first embodiment of the present invention will be described.

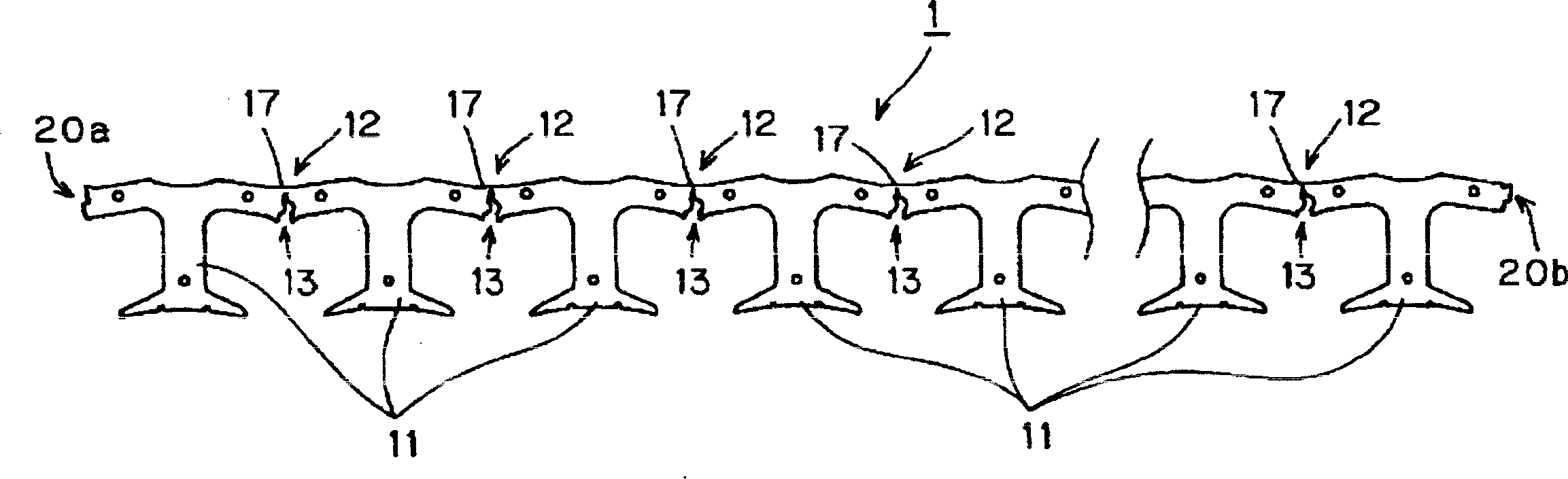

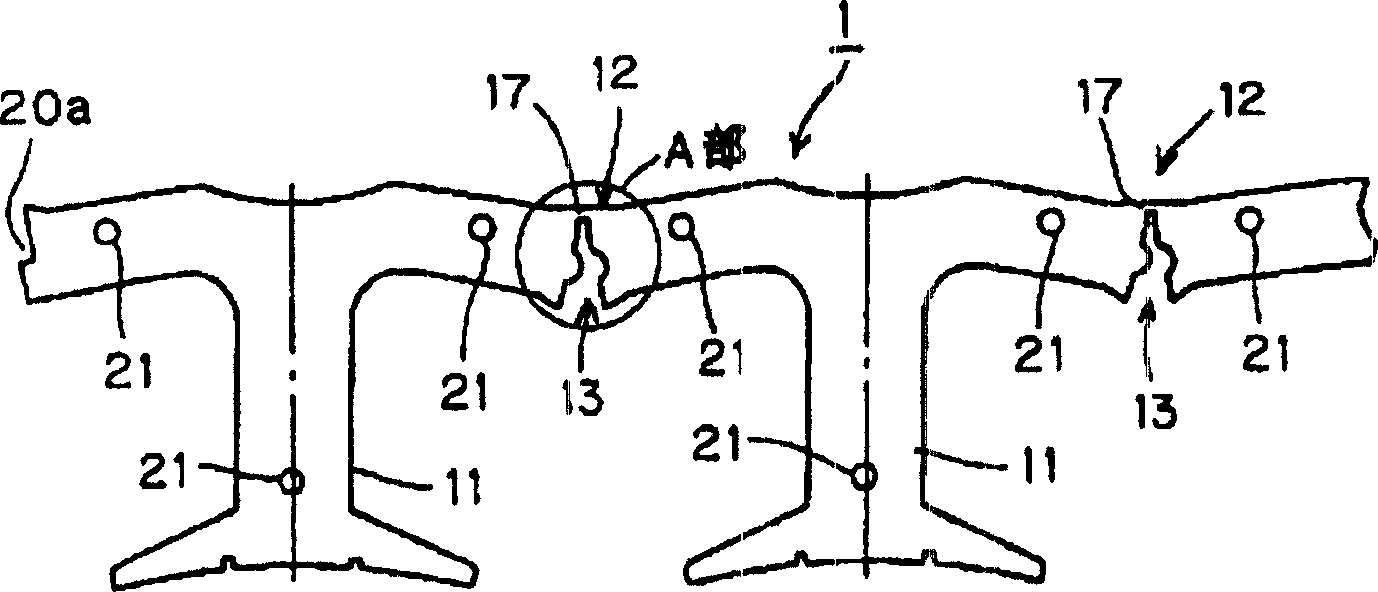

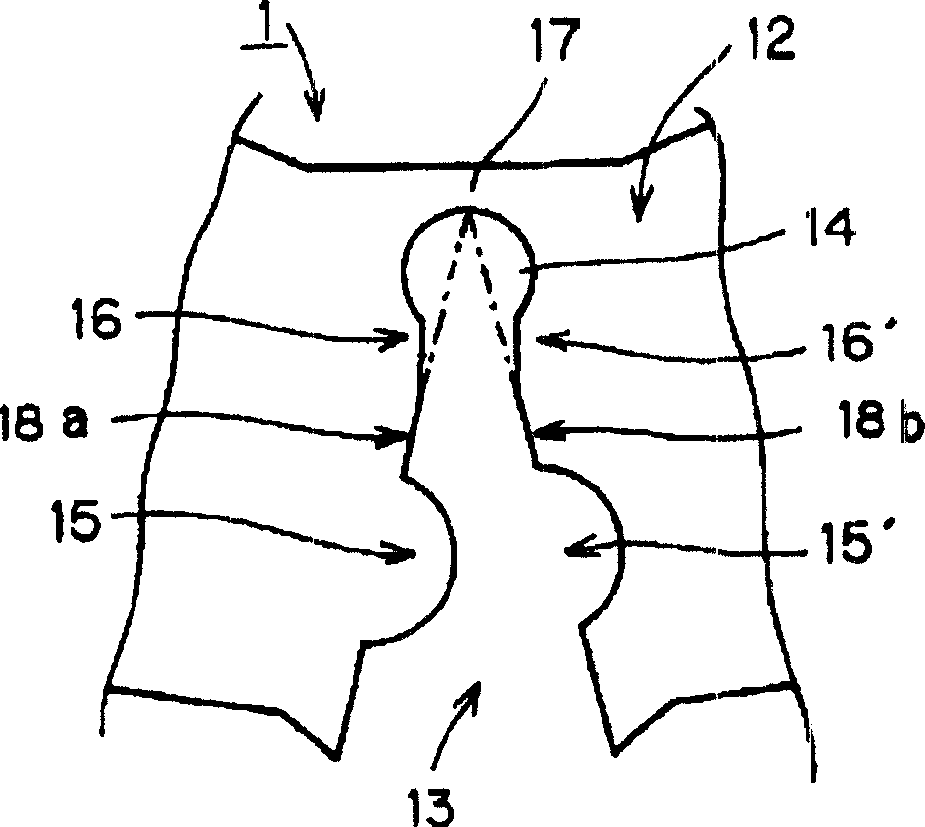

[0035] figure 1 It is a plan view of the straight core 1 constituting the core of the brushless DC motor. figure 2 for figure 1 A partially enlarged view of the straight iron core 1 shown, image 3 It is a V-shaped notch provided on the bending part of the core ( figure 2 A magnified view of part A).

[0036] Such as figure 1 , 2 As shown, a straight iron core 1 is formed by punching laminated silicon steel sheets with a press using a punching die, and a plurality of T-shaped tooth portions 11 pass through the notch of the core bending portion 12 having a V-shaped notch portion 13 The narrow connecting portion 17 at the bottom of the portion 13 is connected in a strip shape, and the screw hole 21 is opened at a predetermined position, and the connecting portions 20a, 20b for bending the straight core 1 to be connected in a ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com