Dress material and method for producing dress material

A manufacturing method and technology of clothing materials, which are applied to textiles and papermaking, tools for sewing clothes, seams of textile materials, etc., can solve the problems of poor appearance and achieve low internal stress, high hardness and rigidity, and small wrinkles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

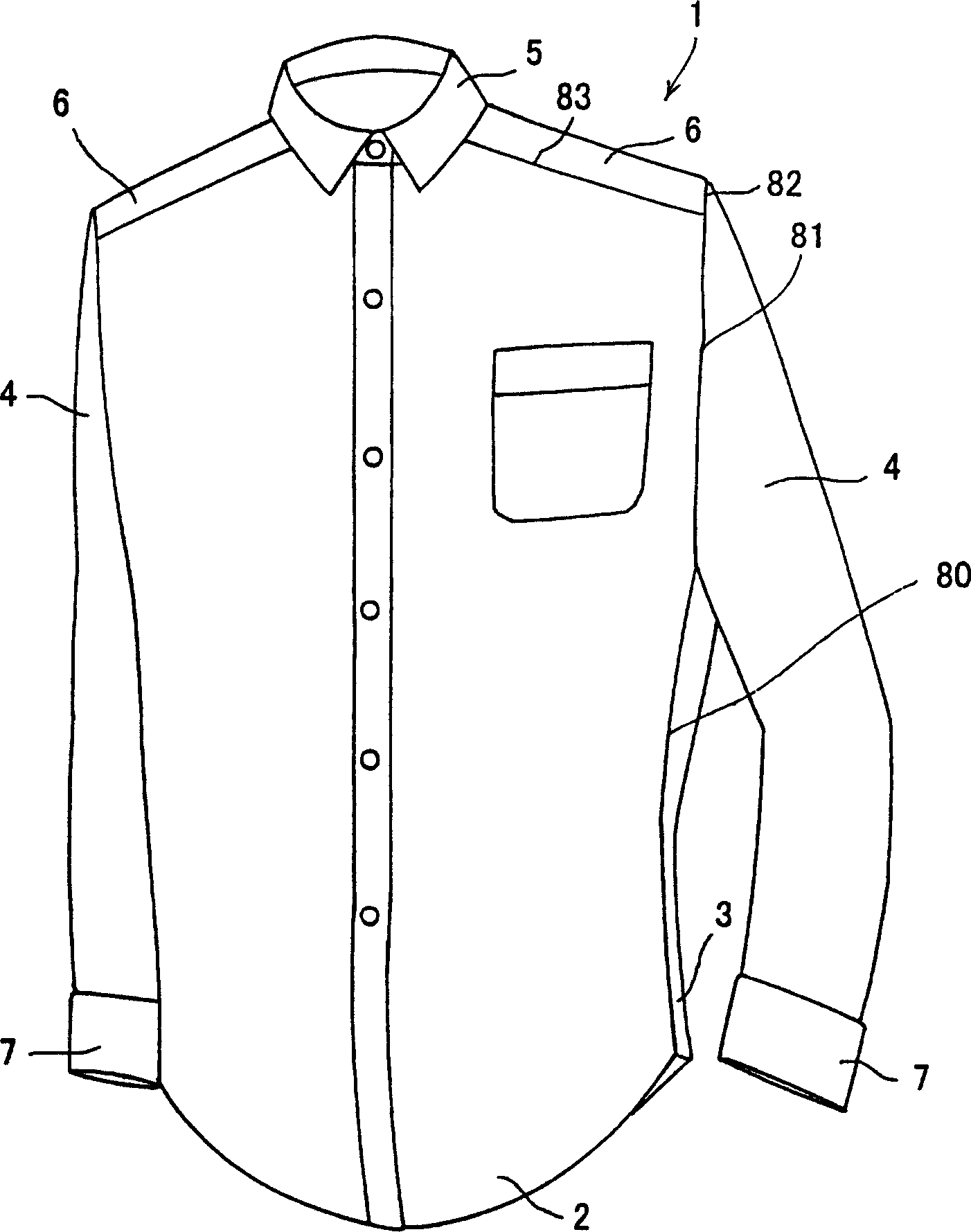

[0071] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In this embodiment mode, the present invention is applied to a white shirt. The white shirt 1 ( figure 1 ) is to be cut into the part of the prescribed shape of the front body 2, the back body 3, the sleeve 4, the collar 5, the shoulder 6, and the cuff 7, and is made by sewing.

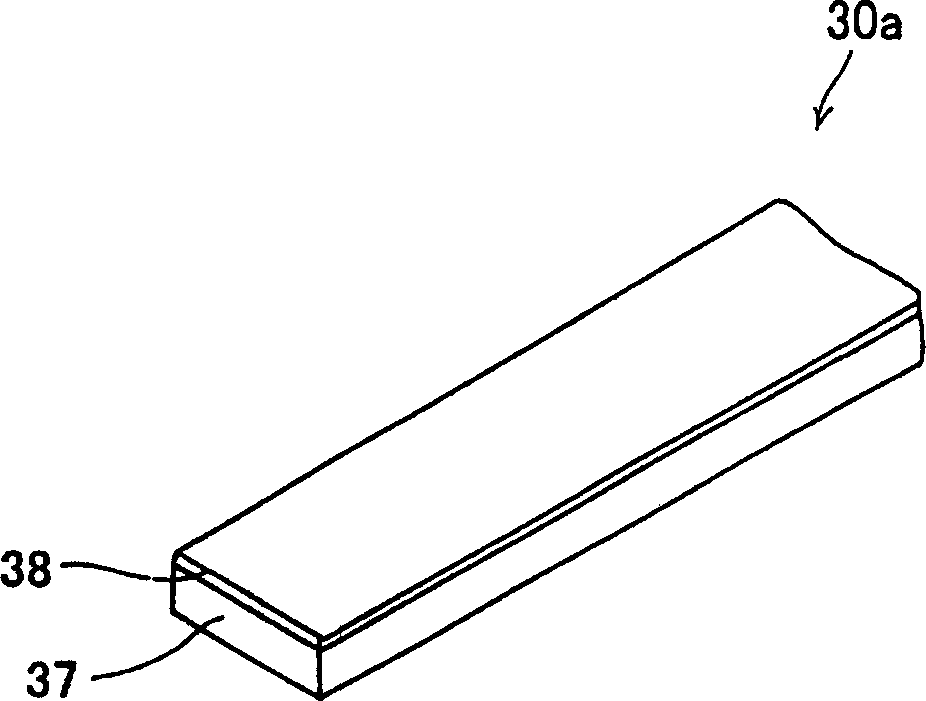

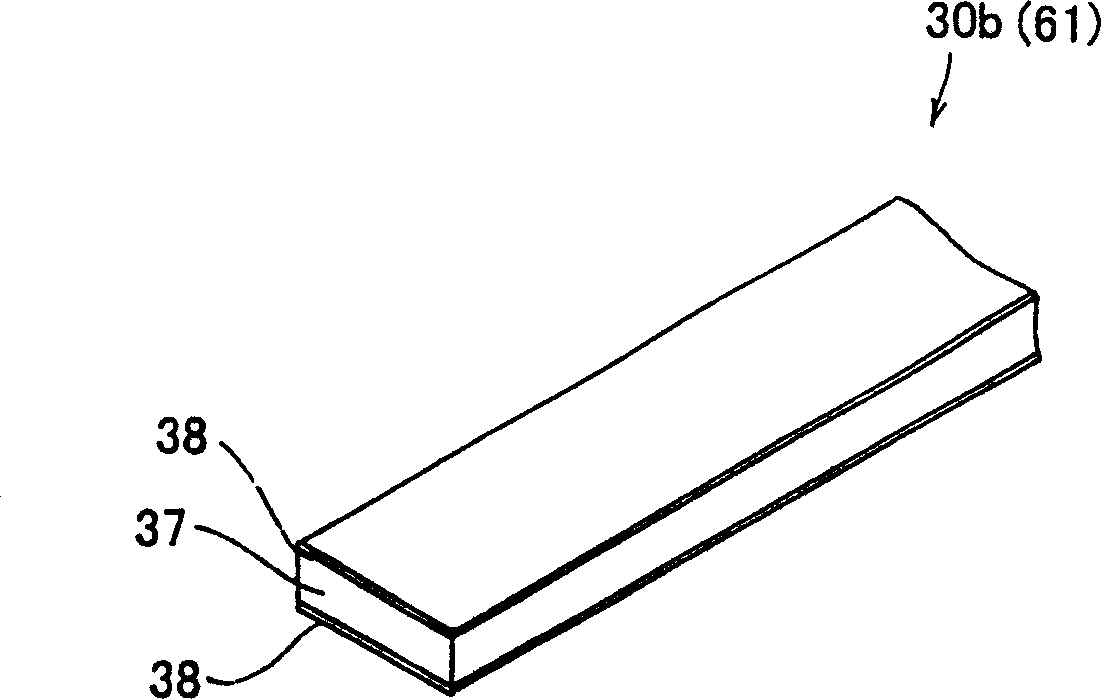

[0072] In addition, at the joint part (side seam part) 80 of the front body 2 and the back body 3, the joint part (arm hole sewing part) 81, 82 of the sleeve 4 and the front and rear garment parts 2, 3 and the shoulder 6 (the sleeve 4 and the The connecting portion of the back body 3 is not shown in the figure), the joint 83 of the shoulder 6 and the front body 2 and the back body 3 (the joint of the shoulder 6 and the back body 3 is not shown in the figure), and The characteristic structure of the present invention is employed in the joining portion (not shown) of the cylindrical portion of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com