Organic electroluminescent assembly and manufacturing method thereof

A technology of electroluminescence and manufacturing method, applied in electroluminescence light sources, electric light sources, electrical components, etc., can solve the problems of high risk, difficult to control purity, danger, etc., to improve current density, improve cathode process, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

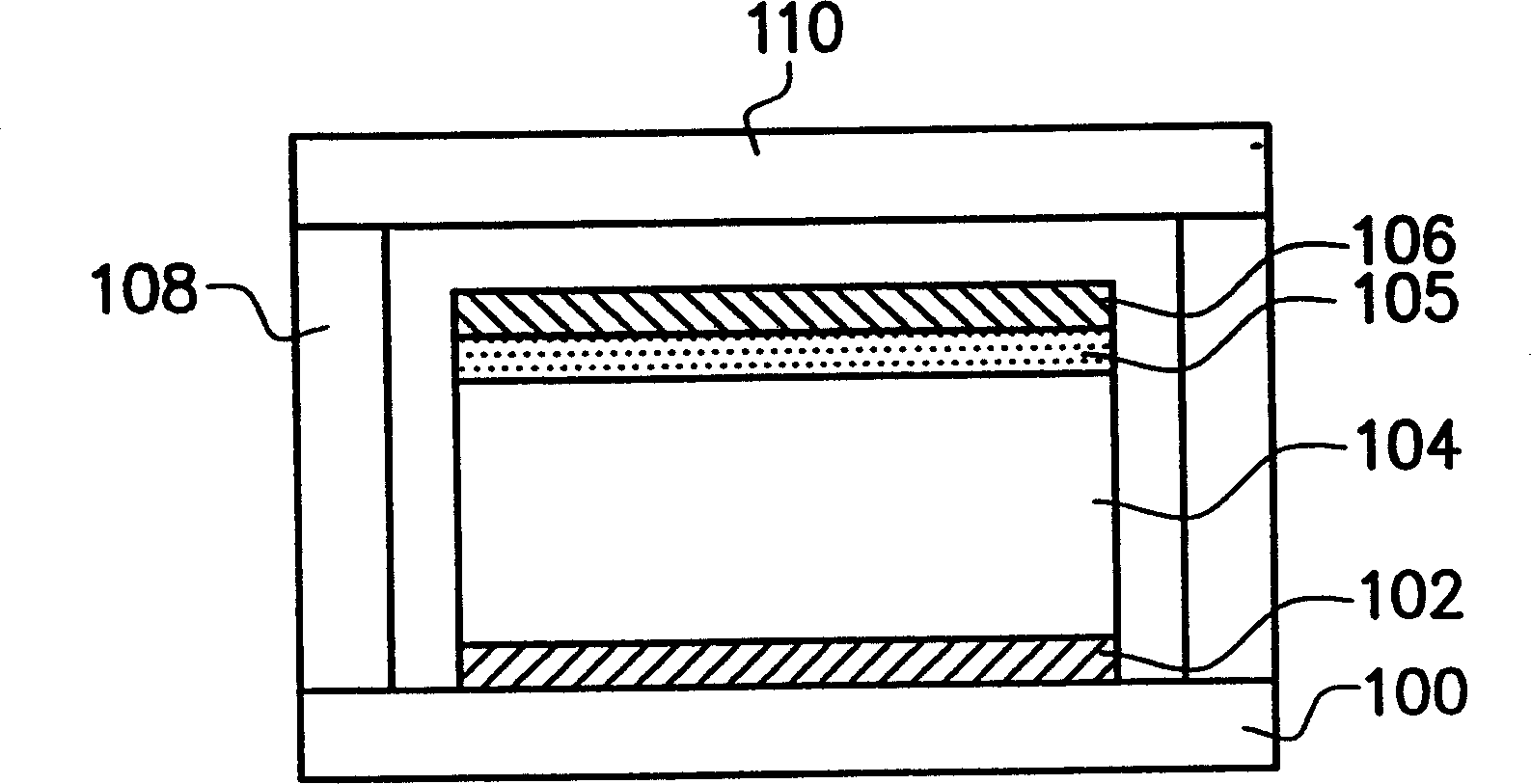

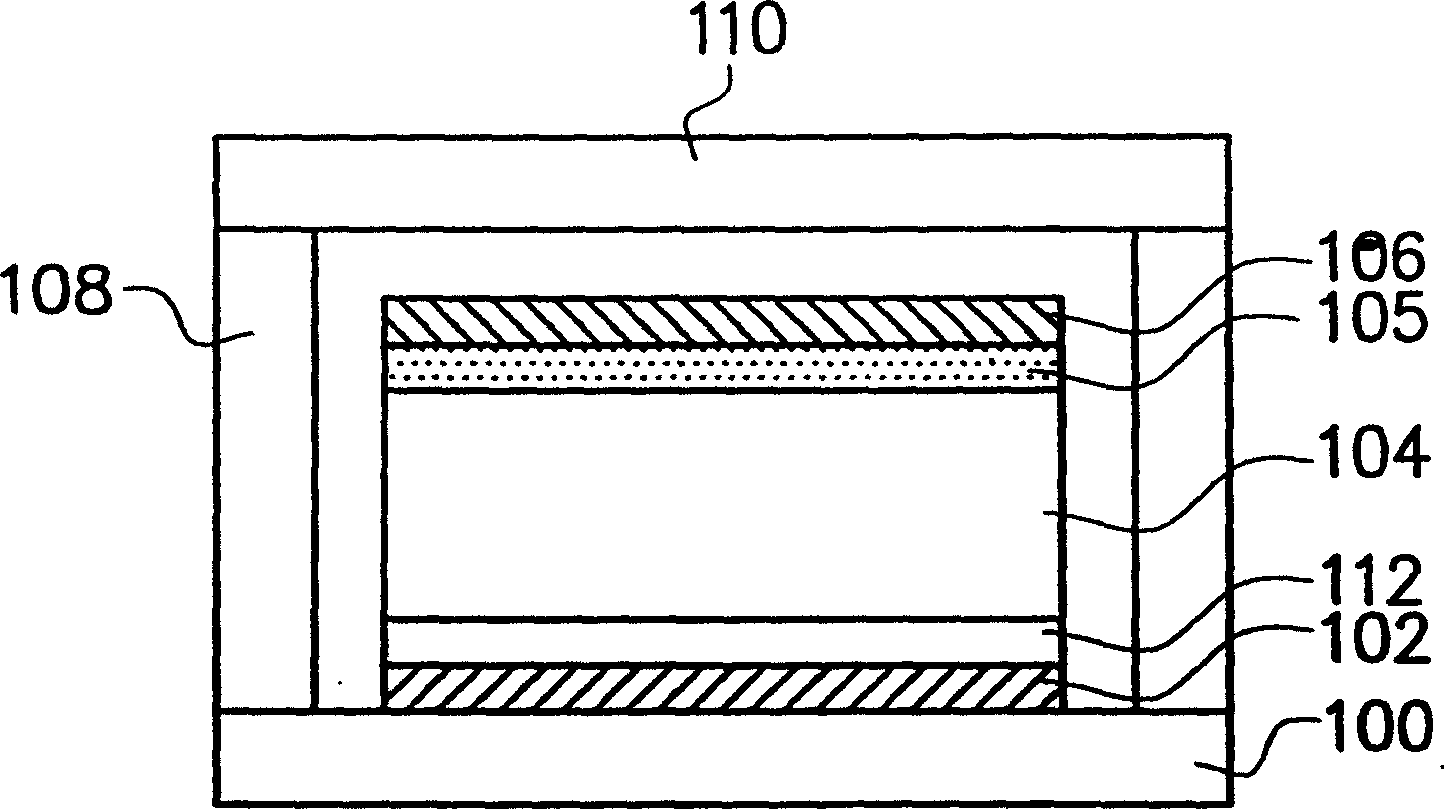

[0039] Such as figure 2 Shown is a schematic cross-sectional view of an organic electroluminescent device according to an embodiment of the present invention.

[0040] refer to figure 2 , the organic electroluminescent component in the figure is a two-layer structure component, which includes a transparent substrate 100, an anode 102, a light emitting layer 104, an ion-doped layer 105, a cathode 106, a cover plate 110 and a Frame glue 108. The method of forming the organic electroluminescent device is to sequentially form the anode 102 , the light emitting layer 104 , the ion-doped layer 105 and the cathode 106 on the transparent substrate 100 . Afterwards, a cover plate 110 is formed on the cathode 106, and a frame glue 108 is formed around the transparent substrate 100 and the cover plate 110, so as to encapsulate the organic electroluminescence component.

[0041] Wherein, the transparent substrate 100 is, for example, a glass substrate, a plastic substrate or a windab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com