High efficiency energy saving electromechanical hybrid stepless gear

A continuously variable transmission, high-efficiency and energy-saving technology, applied to mechanical equipment, the layout of multiple prime movers of general power plants, gear transmissions, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

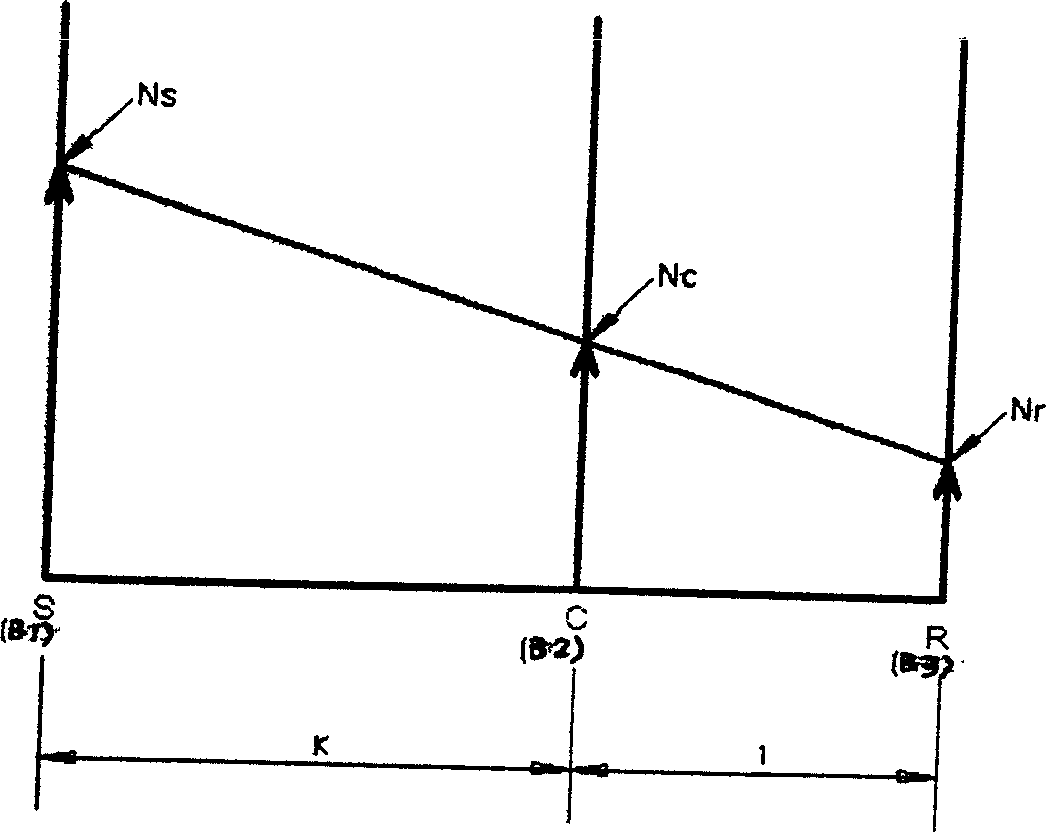

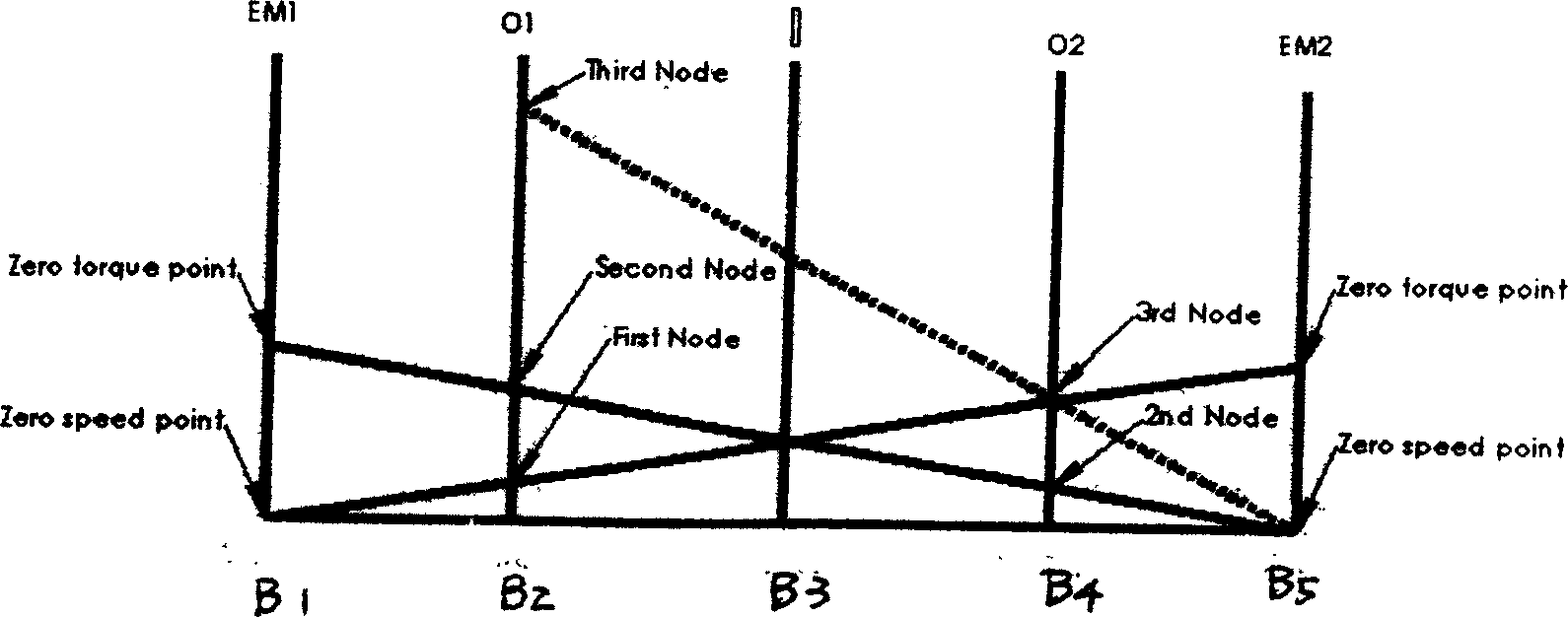

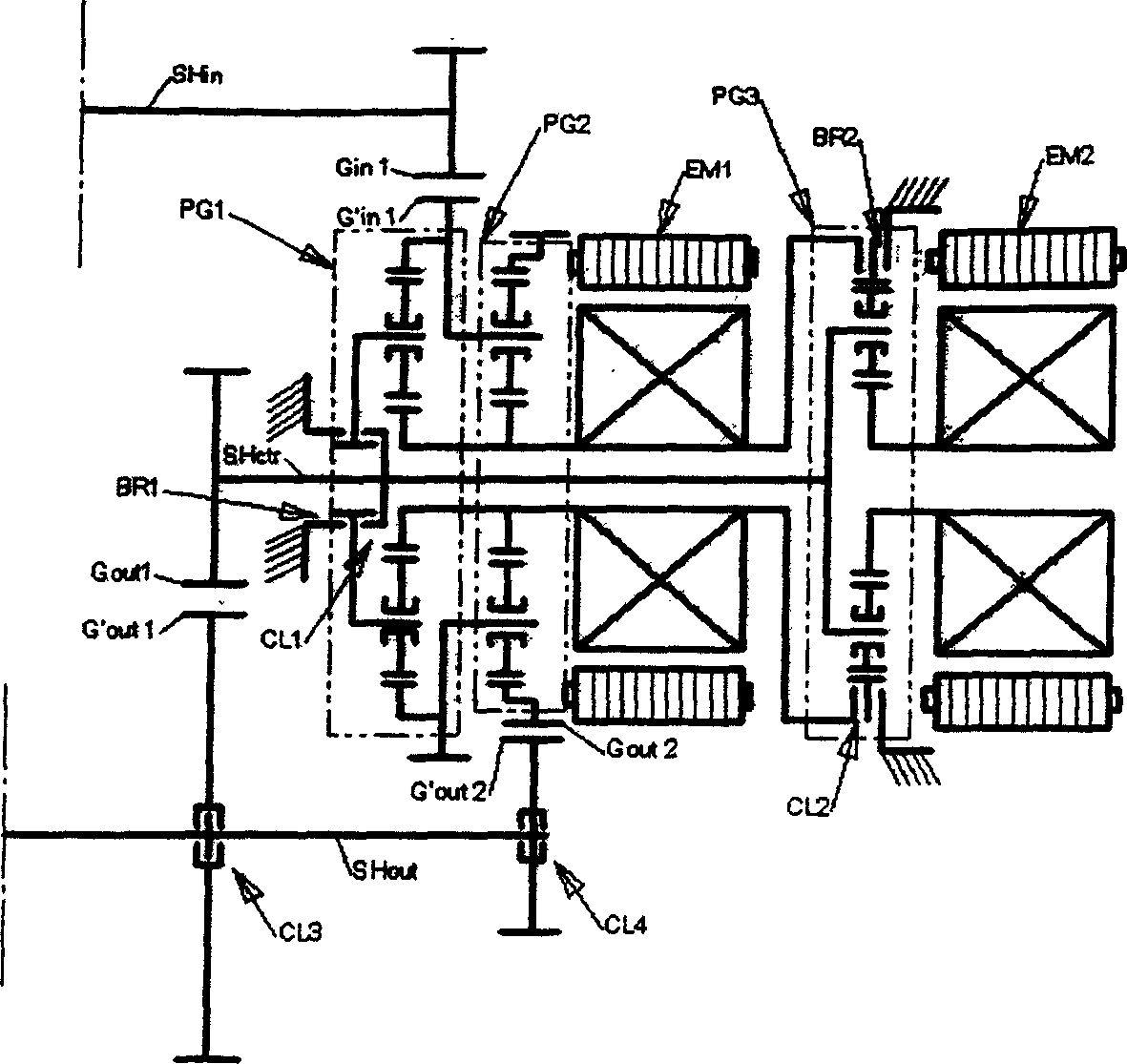

[0038] Such as image 3 , Figure 4 As shown, the continuously variable transmission consists of three planetary gear trains (PG1, PG2, PG3), two motors (EM1, EM2), a motor controller (CTL) and a set of clutches (CL1, CL2, CL3, CL4, BR1, BR2) composition. The program also includes an input shaft (SH in ) an output shaft (SH out ) and several pairs of gears (G in 1, G' in 1, G out 1, G' out 1, G out 2, G' out 2). Each planetary gear train consists of a ring wheel (R1, R2, or R3), a sun gear (S1, S2, or S3), a set of planetary gears (P1, P2, or P3), and a planetary gear carrier ( C1, C2, or C3) composition. Each motor consists of a rotor (RT1 or RT2) and a stator (ST1 or ST2). Each pair of input gears and each pair of output gears consists of a driving wheel and a driven wheel, the driving wheel is represented by G; the driven wheel is represented by G'.

[0039] When used in electromechanical hybrid vehicles, the solution also includes a accumulator (BT) for the st...

Embodiment 2

[0104] As shown in Figure 7, compared with Embodiment 1, a pair of output gears (G out 3 and G out ’3) and a clutch (CL5). Correspondingly, an additional speed zone for compound power splitting is added. In other words, this embodiment can provide four forward zones and one retrograde zone. The four forward zones include an output power split speed zone and three composite power split speed zones.

[0105] Output gear pair (G out 3, G' out 3) The driving gear (G out 3) with the center shaft (SH ctr ) connected, connected to the second branch of the five-branch system, the driven wheel (G out ’3) through the clutch (CL5) and the output shaft (SH out ) to make selective connections. Except for the compound power split speed zone added at the end, the working state of the motor in other speed zones and the clutch situation of the clutch in the second embodiment are exactly the same as those in the first embodiment. Therefore, no further retelling. The following is only...

Embodiment 3

[0117] Such as Figure 8 As shown, similarly, if a pair of output gears (G out 4 and G' out 4) and a clutch (CL6), and the driving wheel of the output gear pair (G out 4) Connect to the fourth branch of the five-branch system where the third ring wheel (R3) is located, the driven wheel (G' out 4) Selectively connect with the output shaft (SH) through the clutch (CL6) out ) are coupled. Compared with embodiment 2, another speed zone of compound power split flow is obtained, that is, the fourth compound power split flow speed zone. According to the order of the overall forward speed zone, the speed zone of the composite power split is called the fifth speed zone.

[0118] The boundary point between the fourth speed zone and the fifth speed zone is the fourth speed node. The location of the fourth speed node is:

[0119] SR 4 = K 1 K ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com