Mixed line wave thermal sound engine with bouble-end drive

A thermoacoustic engine, a hybrid technology, applied in the direction of machines/engines, mechanisms that generate mechanical power, mechanical equipment, etc., can solve problems such as heater heat waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

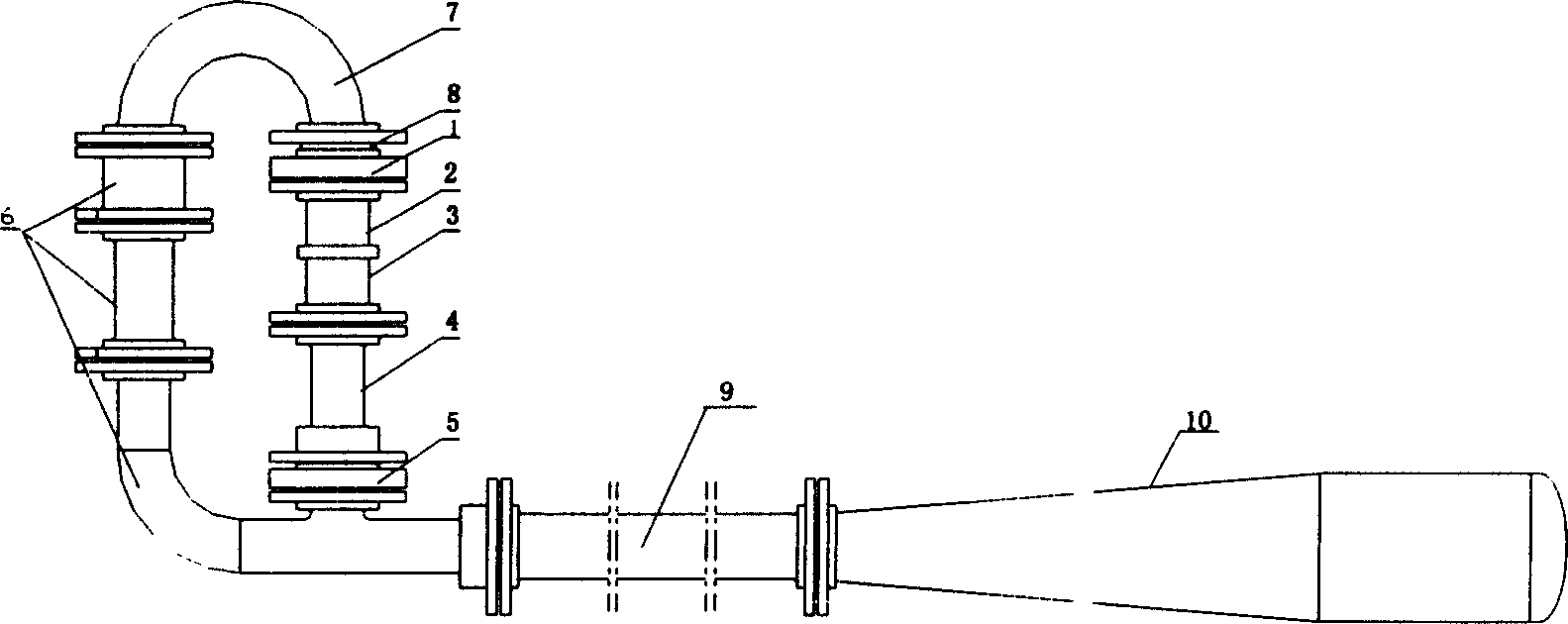

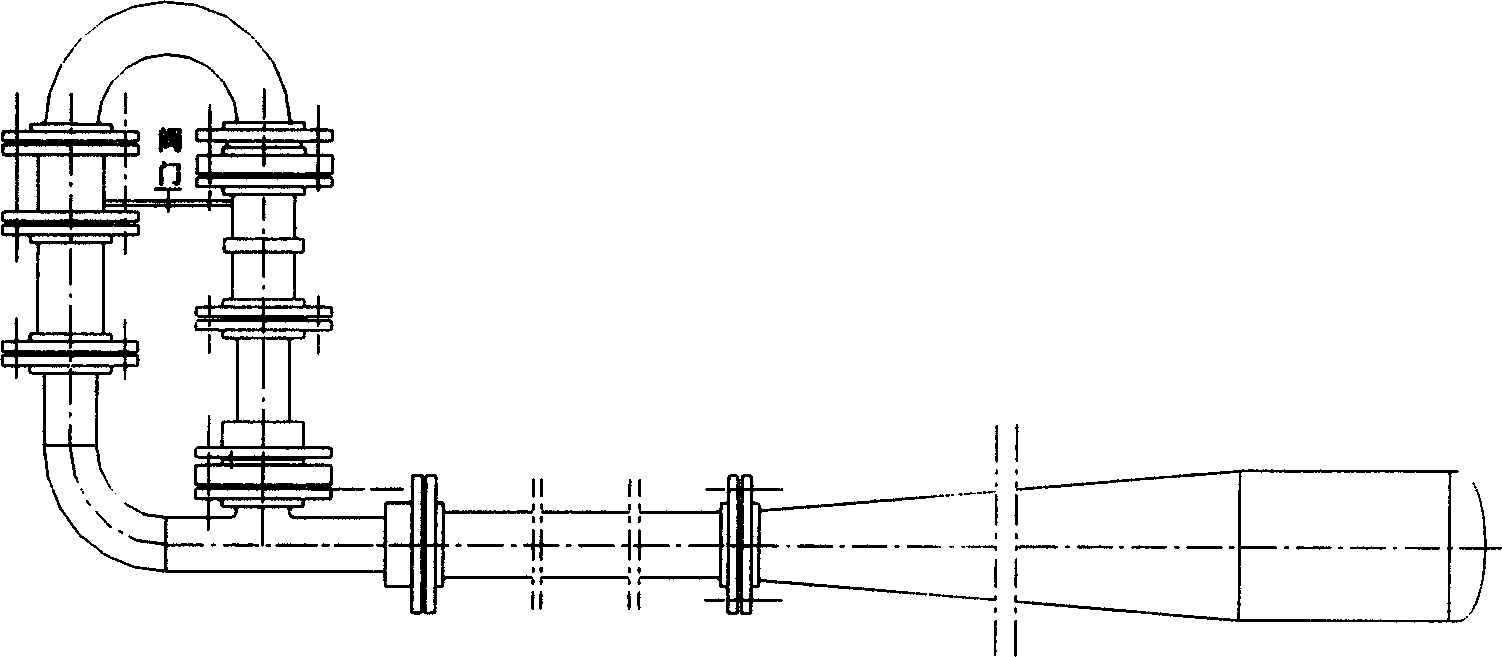

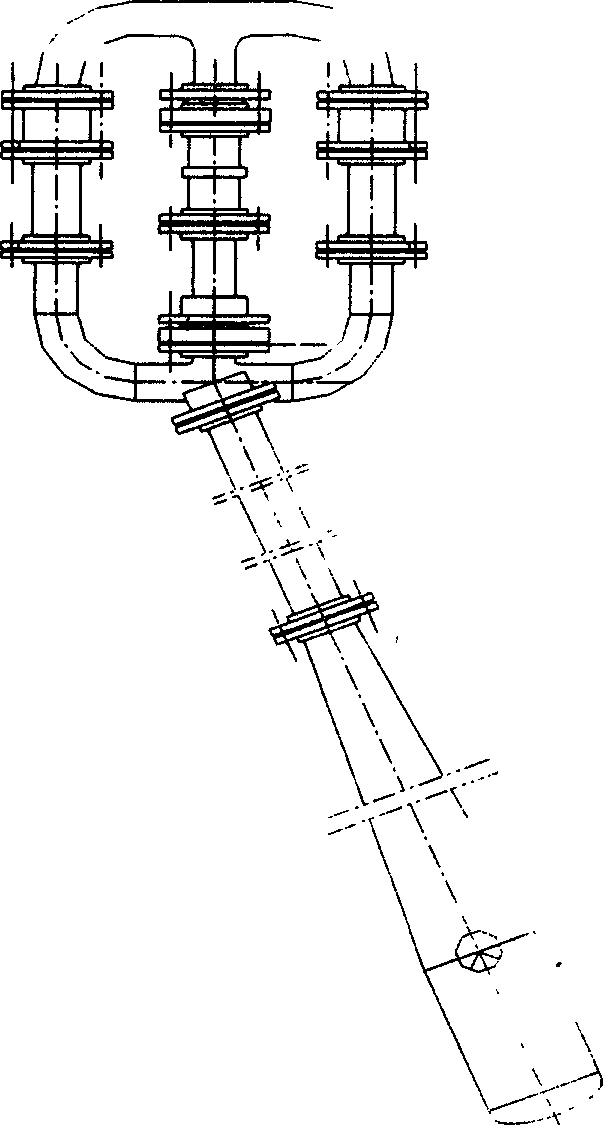

[0030] As shown in the figure, the dual-end driven hybrid traveling wave thermoacoustic engine includes a feedback pipeline 6, a sound volume pipeline 7, a jet pump 8, a main cooler 1, a thermoacoustic regenerator 2, and a heater 3 connected in sequence , thermal buffer tube 4, sub-cooler 5 and a traveling wave loop structure thermoacoustic generator and a straight resonant path 9, the same or a similar traveling wave loop structure thermoacoustic generator is connected to the other end of the resonant straight path 9.

[0031] A bypass structure is provided between the feedback pipeline 6 of the thermoacoustic generator with a traveling wave loop structure connected at one or both ends of the resonant straight path 9 and the thermoacoustic regenerator 2 . The sound capacity pipeline 7 of the thermoacoustic generator with traveling wave loop structure connected to one or both ends of the resonance straight path 9 is connected to the inlet of the resonance straight path 9 with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com