Liquid crystal shutter device

A technology of liquid crystal shutters and liquid crystals, applied in printing, optics, instruments, etc., can solve problems such as uneven band images, complex optical systems, and increased printing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

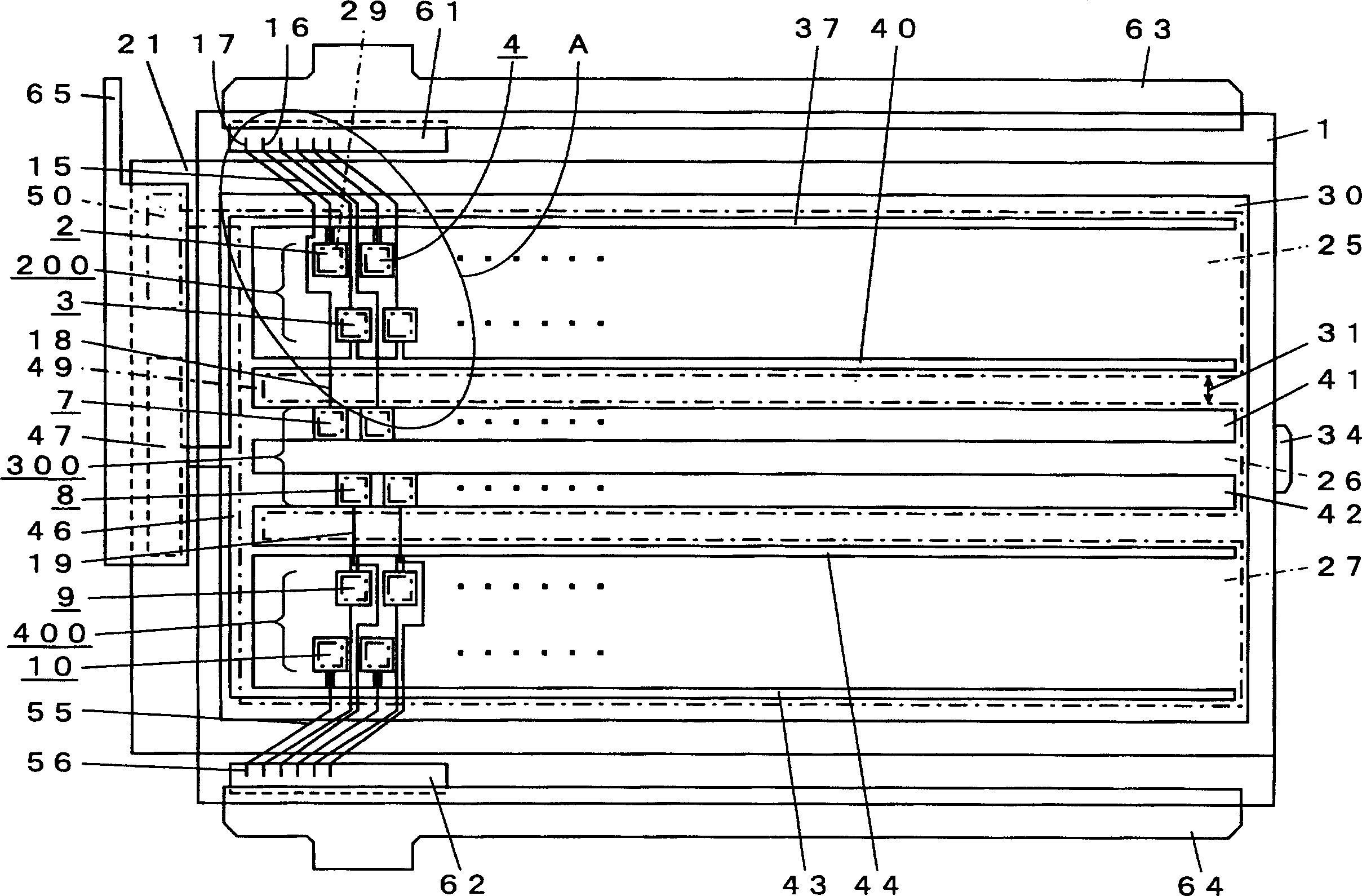

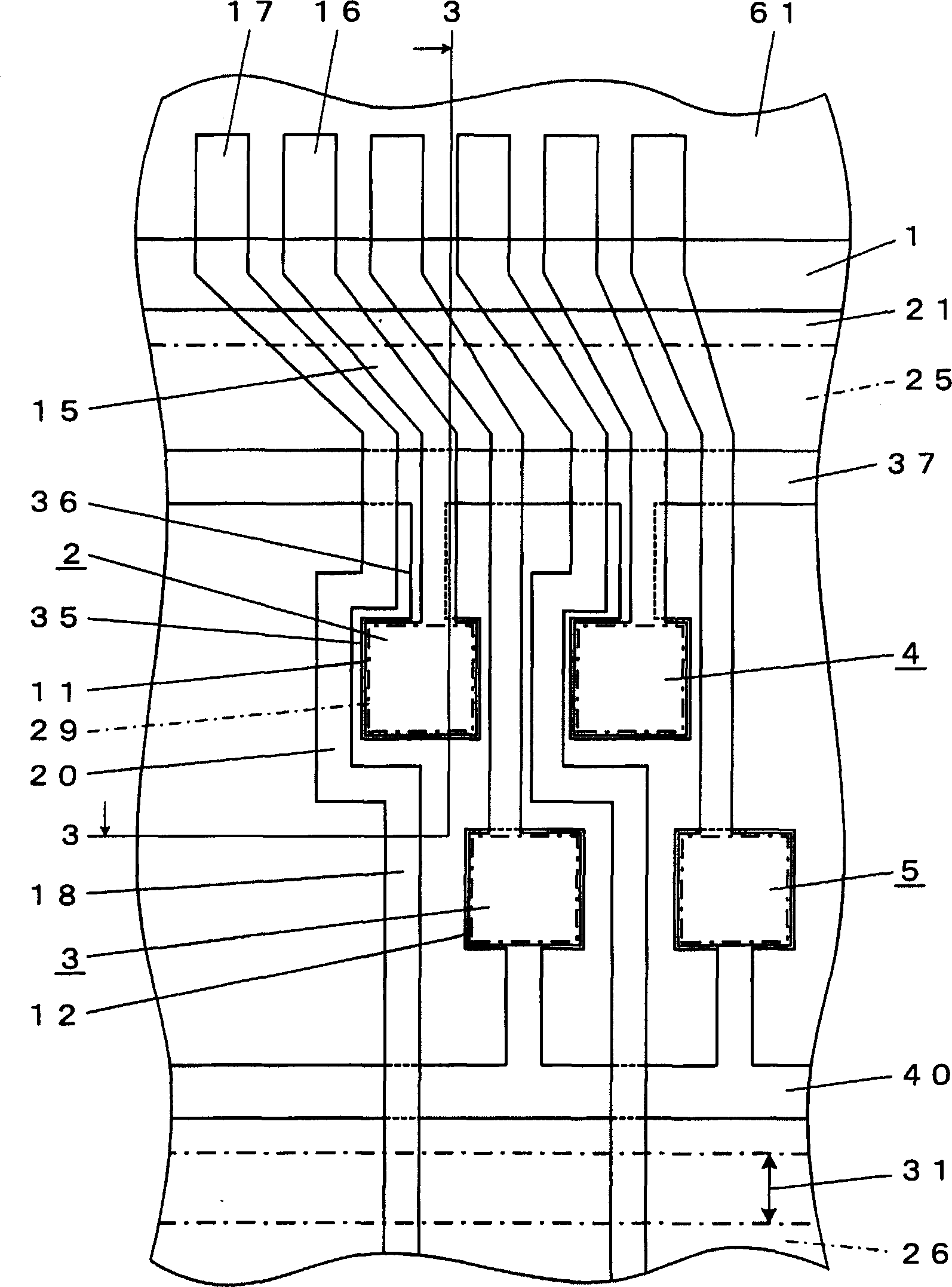

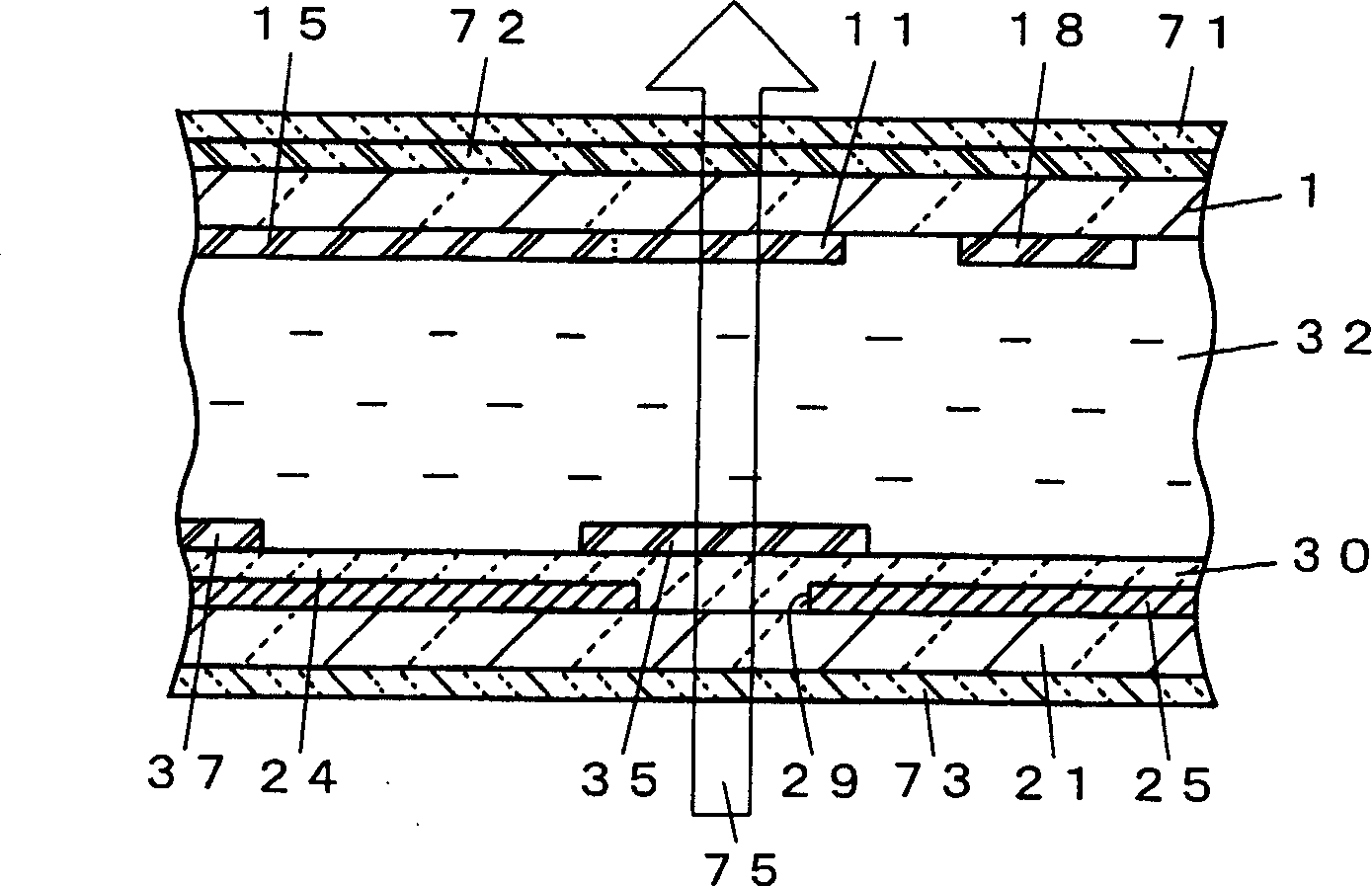

[0076] (the first embodiment: Figure 1 to Figure 7 )

[0077] First, a first embodiment of the liquid crystal shutter device of the present invention and an optical printer including the liquid crystal shutter device will be described. figure 1 is a plan view for explaining the arrangement of electrodes and light-shielding films in the liquid crystal shutter device, figure 2 is zoomed in figure 1 A partial plan view of a part of the ellipse A, image 3 is shown along figure 2 A partial sectional view of a part of the 3-3 line section, Figure 4 It is a schematic diagram for explaining the operation of the optical printer described above. Figure 5 is along Figure 4 The schematic cross-section of the 5-5 line, Image 6 is shown for driving figure 1 The diagram showing the drive signal of the liquid crystal shutter device, Figure 7 It is a figure for demonstrating the characteristic of this liquid crystal shutter device. In these drawings, pixels are shown much...

no. 2 Embodiment approach

[0122] (the second embodiment: Figure 8 to Figure 11 )

[0123] Hereinafter, a second embodiment of the liquid crystal shutter device of the present invention will be described. Figure 8 is a partial plan view for explaining the arrangement of electrodes and light-shielding films in the liquid crystal shutter device, Figure 9 are also containing sealing material or insulating film, magnifying Figure 8 Part of the partial floor plan shown, Figure 10 is omitted in Figure 9 diagrams containing sealant and insulating film illustrations, Figure 11 is shown along Figure 9 A partial cross-sectional view of the sectional part of line 11-11. exist Figure 8 , the FPC connected to the liquid crystal shutter device is omitted from the illustration. In these figures, the parts corresponding to the configuration described in the first embodiment are given the same reference numerals.

[0124] This is because the liquid crystal shutter device is different from the first emb...

no. 4 Embodiment approach

[0151] (the 4th embodiment: Figure 15 )

[0152] Next, a fourth embodiment of the liquid crystal shutter device of the present invention will be described. Figure 15 is used to explain the electrode and light-shielding film configuration of this liquid crystal shutter device, and Figure 12 Corresponding local plan. In this figure, the parts corresponding to the configurations described in the first to third embodiments are given the same reference numerals.

[0153] Since this liquid crystal shutter device differs from the liquid crystal shutter device of the third embodiment only in that the sealing material 93 between the contours is provided near the sealing material 33, and in that narrow portions are provided on both the focusing electrode and the extraction electrode, only these point to explain.

[0154] In this liquid crystal shutter device, an inter-profile sealant 93 is provided on the inside of the sealant 33 and on the outside of the region where the insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com