Biological diesel oil and method for preparing same

A biodiesel and petrochemical diesel technology, applied in the preparation of liquid hydrocarbon mixtures, biological raw materials, biofuels, etc., can solve problems such as complex equipment, hidden safety hazards, and large investment, and achieve improved combustion performance, improved power performance, and production technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

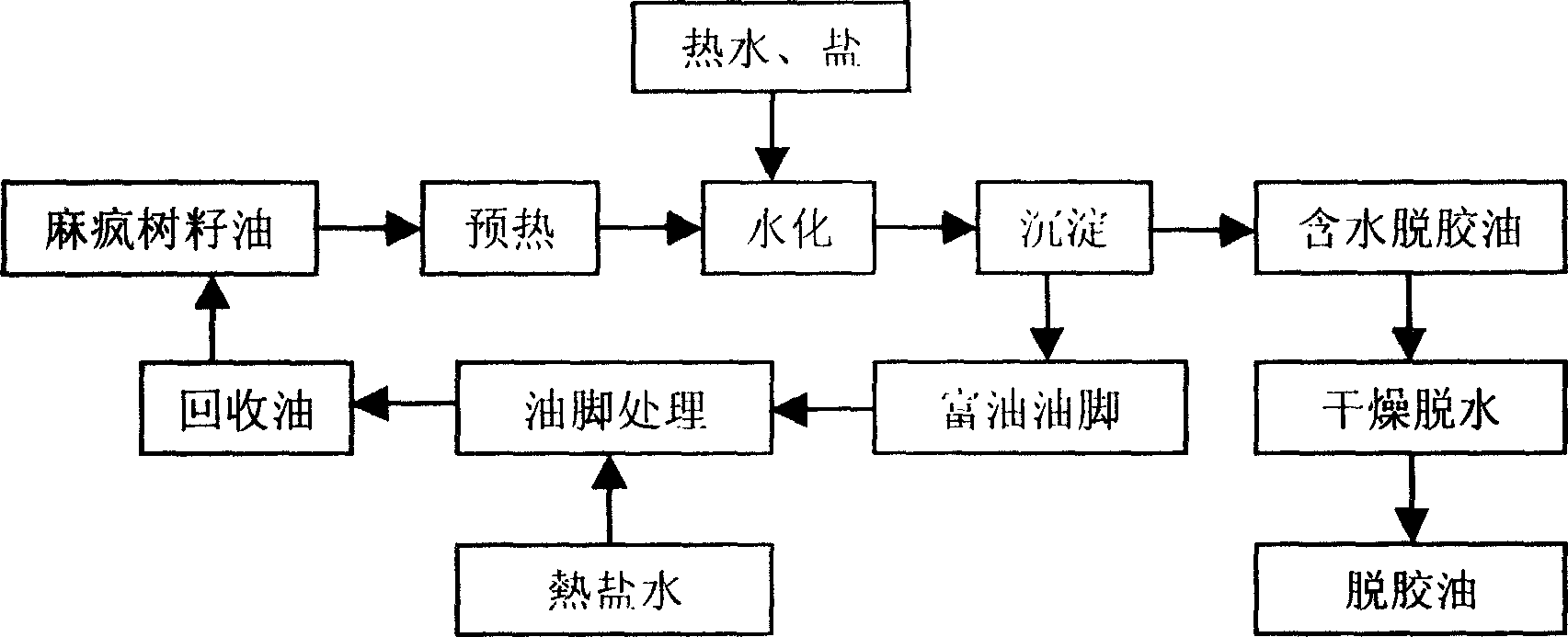

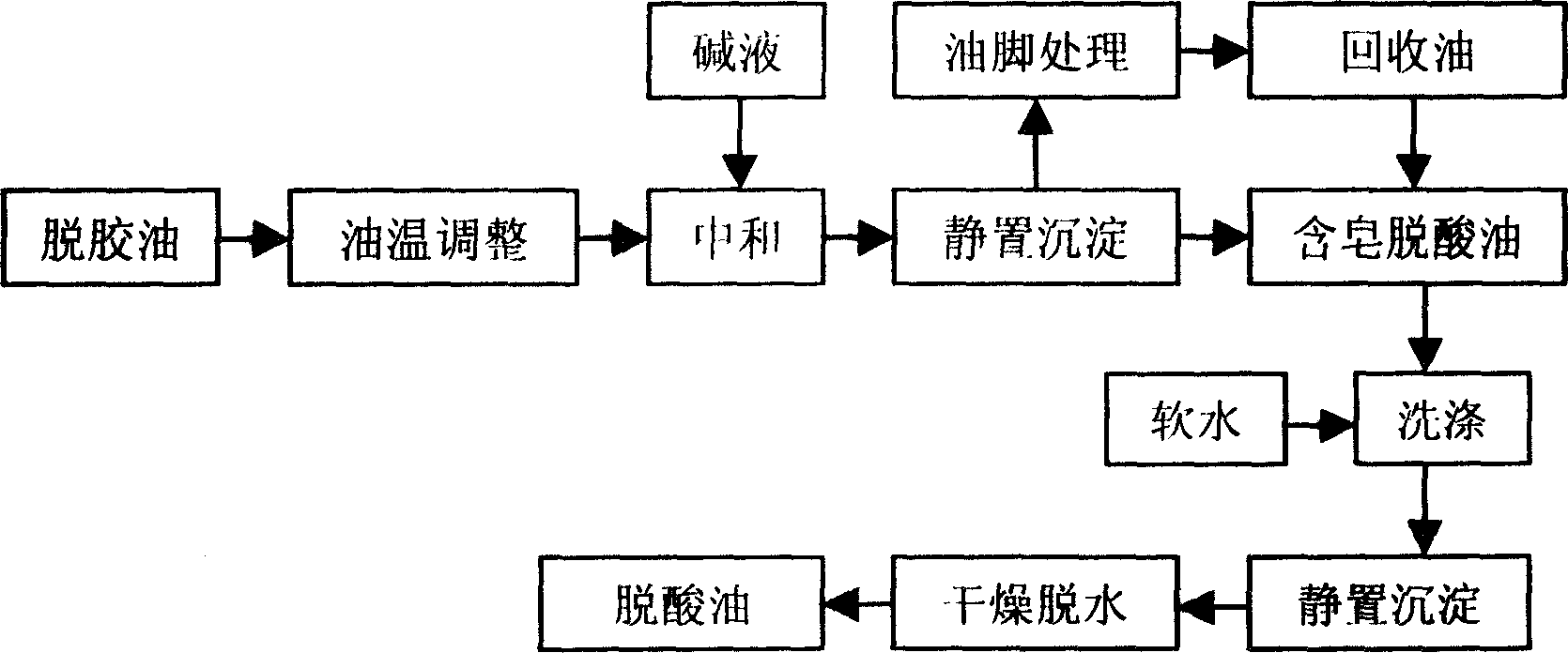

[0018] The preparation method of biodiesel comprises Jatropha seed oil production and Jatropha seed oil refining, modification process; It is characterized in that: described refining, modification process comprises the following steps:

[0019] a. Hydration degumming;

[0020] b. Alkali refining deacidification;

[0021] c. Dehydration;

[0022] d. Intermittent deodorization;

[0023] e. Emulsification or esterification

[0024] The specific emulsification process is that, in the above step e, under the condition that the temperature is 5-50° C., the fatty alcohol is added in a ratio of 2-10% by volume to the jatropha seed refined oil; the preferred process is, Described fatty alcohol is methyl alcohol, ethanol or ethylene glycol; Another kind of preparation technology is, prepares biodiesel with jatropha seed refined oil esterification; : Add methanol or ethanol in a ratio of 3 to 1:6, use sodium hydroxide or sodium methoxide as a catalyst, control the temperature at 35 ...

Embodiment

[0026] 1. Jatropha seed oil production process

[0027] 1. Raw materials: Jatropha curcas L. seeds

[0028] After the Jatropha curcas bears fruit, the pericarp turns yellow and can be harvested. The harvested Jatropha curcas fruits are manually or mechanically peeled to obtain Jatropha curcas seeds, and the peeling rate is required to be >99%. The Jatropha curcas seeds are air-dried so that the moisture content is less than 6%, and the Jatropha curcas seed shells are black and bright, and then they can be put into storage.

[0029] 2. Pretreatment

[0030] 2.1 Remove impurities

[0031] Various impurities in Jatropha seeds are removed by cleaning, screening, air separation, magnetic separation, etc.

[0032] 2.2 Shelling

[0033] The peeling-separation combination machine is used to peel off the shell of Jatropha curcas seeds, and separate the shells and kernels to obtain the Jatropha curcas seeds kernels. The peeling rate is required to be >95%.

[0034] 2.3 Broken

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com