Ultra high energy spark plug

A spark plug, ultra-high technology, applied in the field of spark plugs, can solve problems such as unsuitable, unable to achieve high voltage and high current at the same time, and limited discharge energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

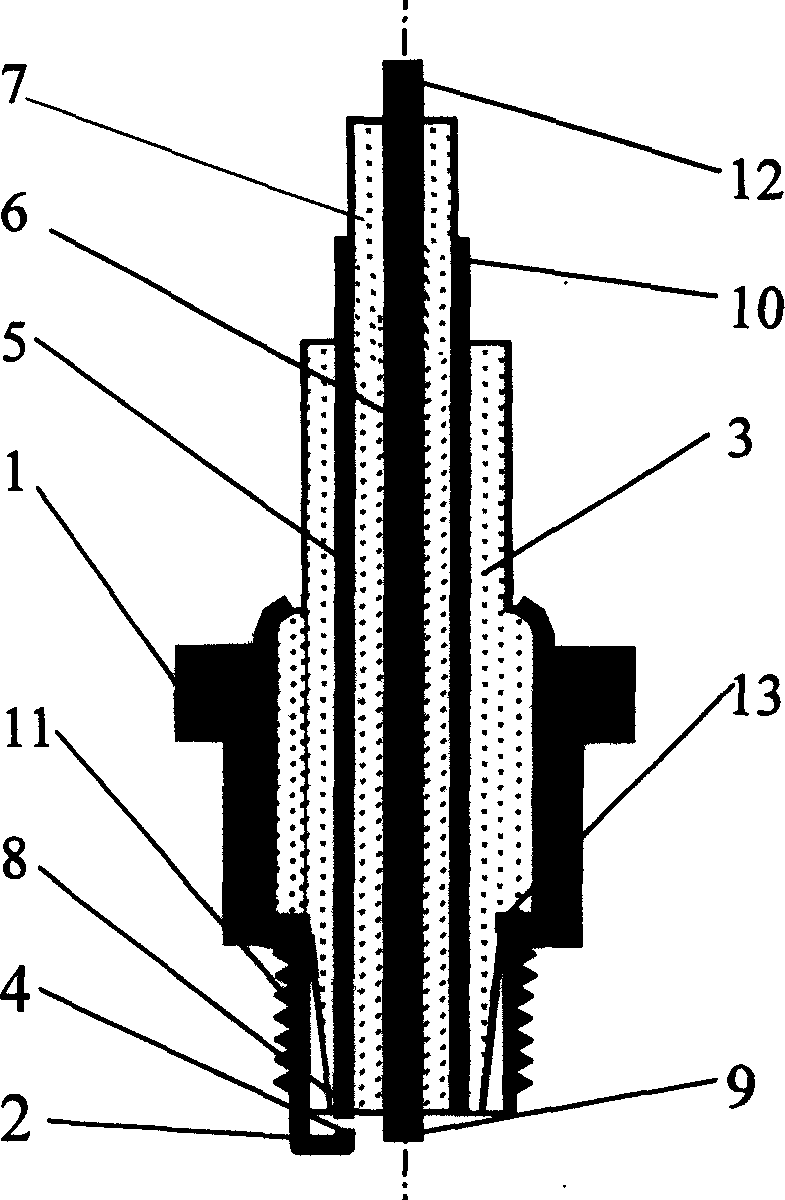

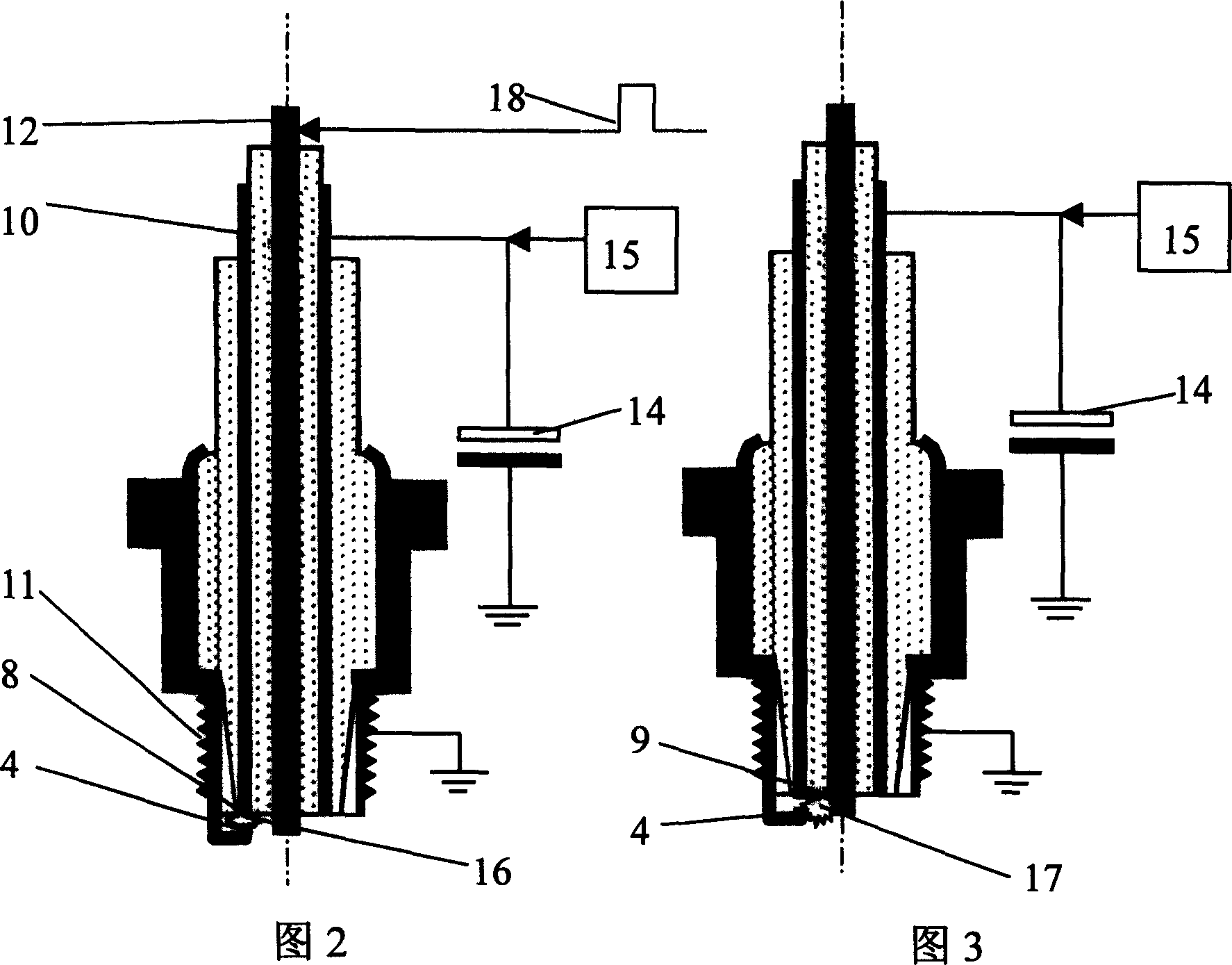

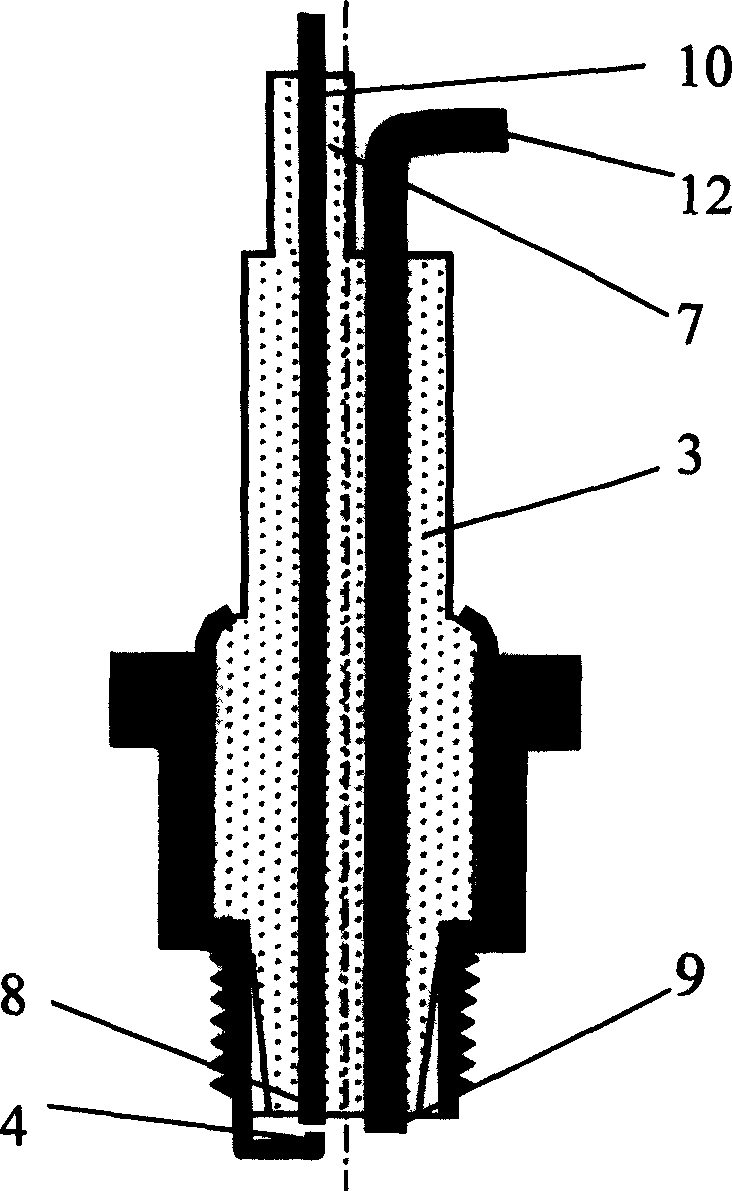

[0010] as attached figure 1 As shown, the ultra-high-energy spark plug is composed of a shell 1, a side electrode 2, and an insulator 3, wherein the shell 1 and the side electrode 2 are integrated by welding. The insulator 3 is located inside the housing 1 , the lower part of the housing 1 has a mounting thread 11 , and the lower end of the side electrode 2 is the discharge terminal 4 of the side electrode. Inside the shell 1, there is a high-voltage electrode 5 and a high-energy electrode 6, and the high-voltage electrode 5, high-energy electrode 6, and the shell 1 are separated by an insulator 3. The lower end of the high voltage electrode 5 is the high voltage electrode discharge end 8 , and the upper end is the high voltage electrode input end 10 . The lower end of the high-energy electrode 6 is the high-energy electrode discharge end 9 , and the upper end is the high-energy electrode input end 12 . The distance between the high-voltage electrode discharge end 8 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com