Pipeline connection external thread oxial rolling machine

A technology for external thread and thread rolling machine, which is applied to threaded products, thread trimmers, applications, etc., can solve the problems of reducing thread assembly allowance, etc., and achieve the effects of reliable and stable working performance, simple structure, and simple and reasonable structure setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

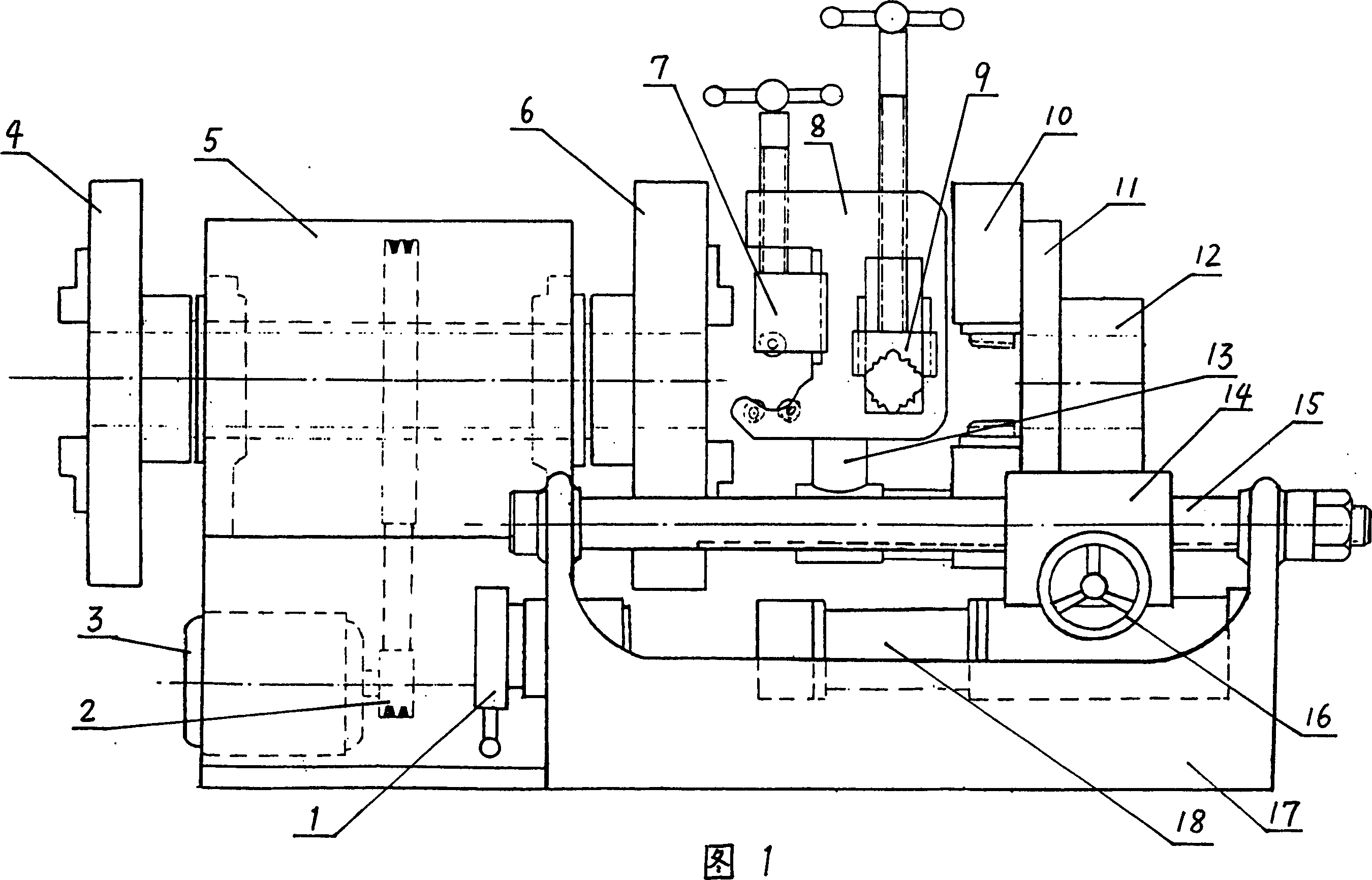

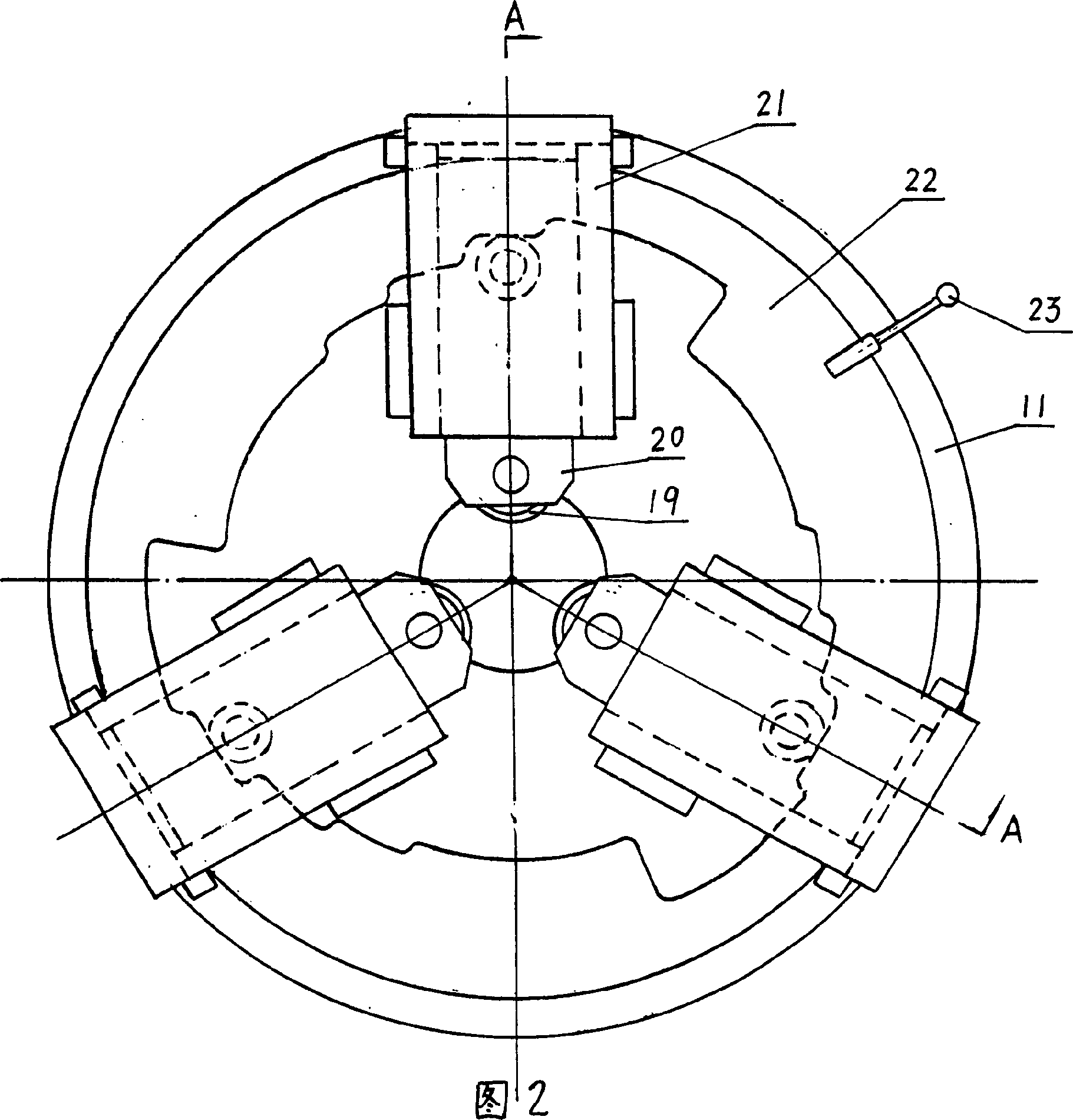

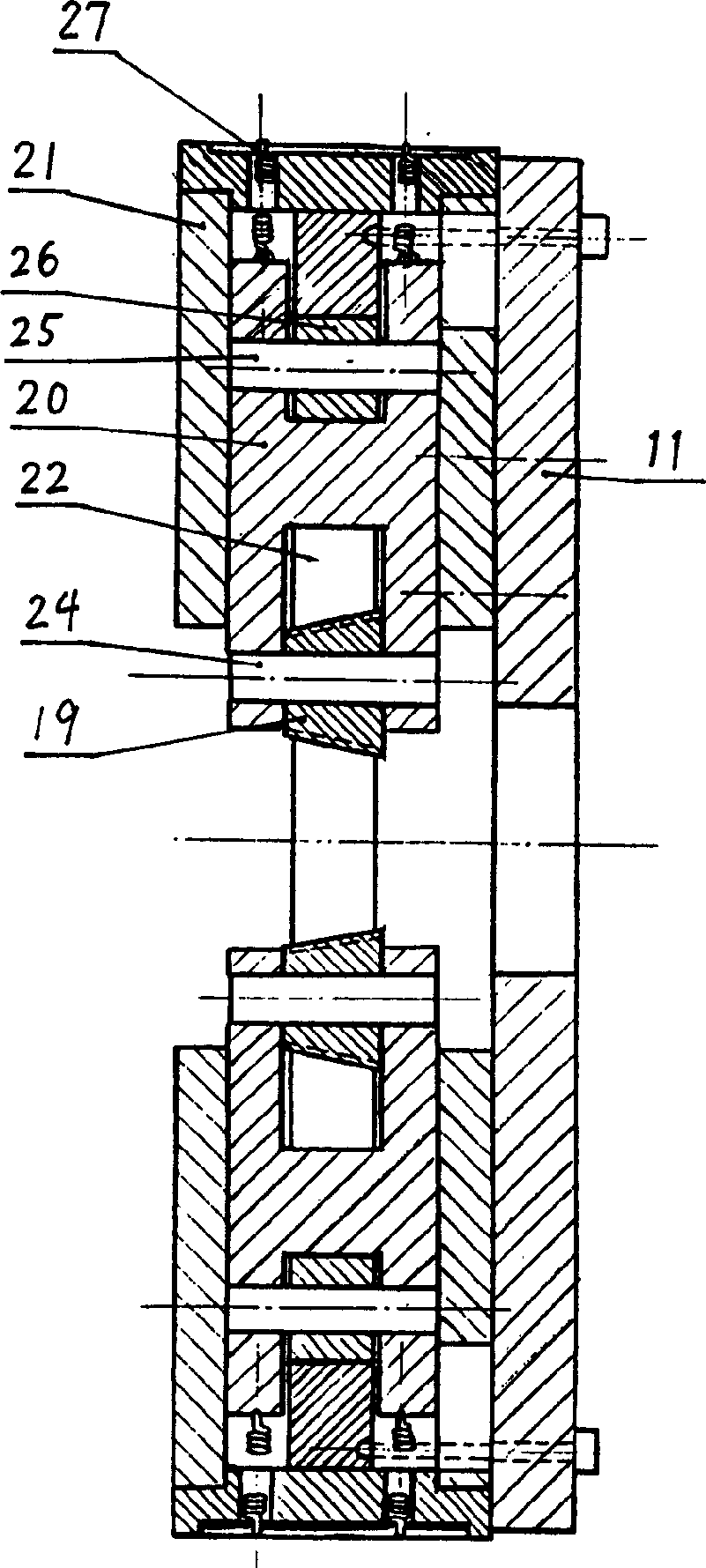

[0017] As shown in Figure 1, it includes an organic base 7, and a spindle box 5 is installed on one side of the upper part of the base. To clamp the pipe to be processed, a rear chuck 4 can also be arranged at the rear end of the spindle box to facilitate the clamping of long pipes; on the other side of the upper part of the machine base, two axial guides are installed in front and behind parallel to the centerline of the spindle. Column 15, slide plate 14 is arranged on the guide post, and gear and hand wheel 16 are arranged on the slide plate, and the gear and the rack set on the front axial guide column are arranged to form a hand-operated mobile slide plate; on the slide plate A thread rolling roulette 10 coaxial with the main shaft is installed on one side of the relative spindle box. The thread rolling roulette includes a chassis 11 connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com