On line autrasonic cleaning and filtering device

A filter device, ultrasonic technology, applied in the direction of filtration separation, fixed filter element filter, semi-permeable membrane separation, etc., can solve the problems of restricting the application of pretreatment filters, the filter cannot run continuously, and the filter is expensive, etc., to achieve Easy to realize automation, good cleaning effect and fast cleaning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

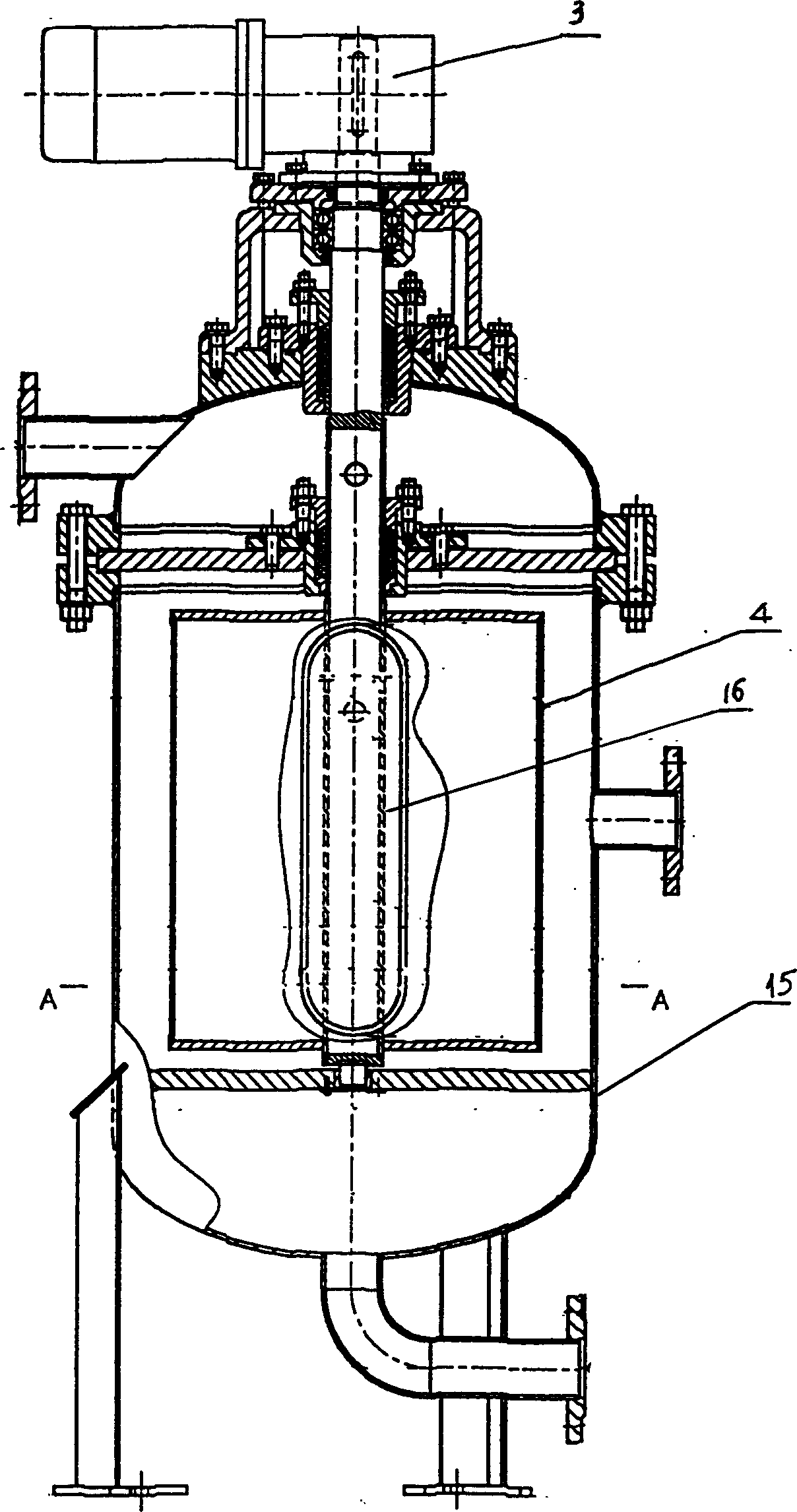

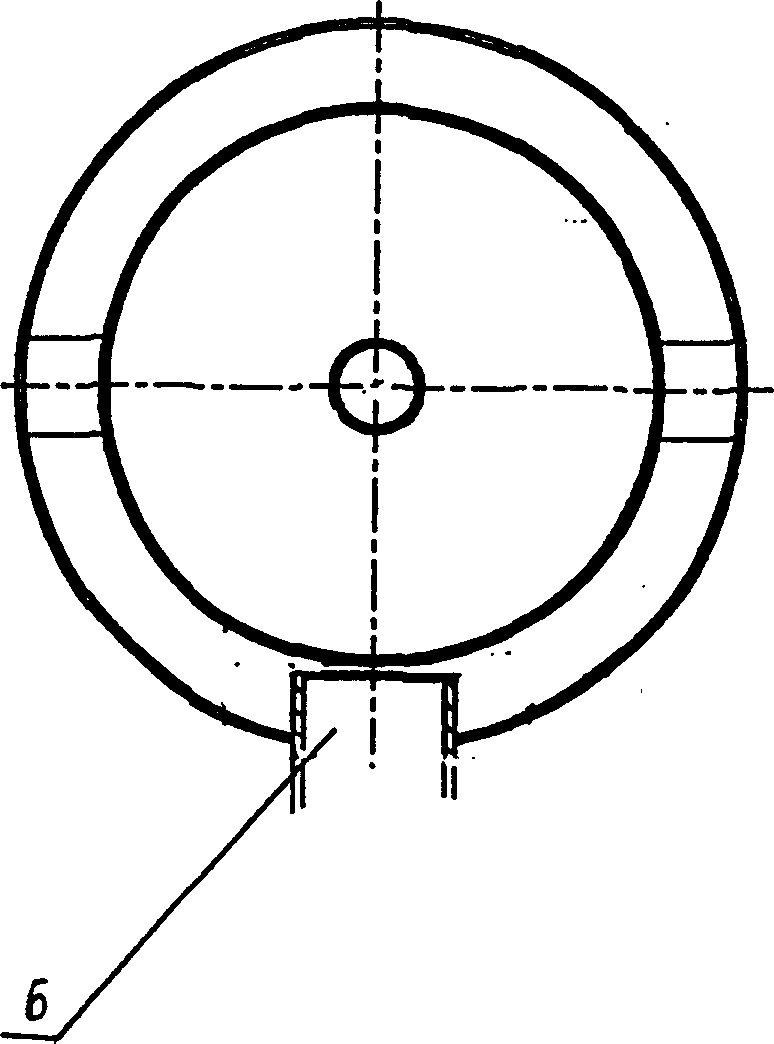

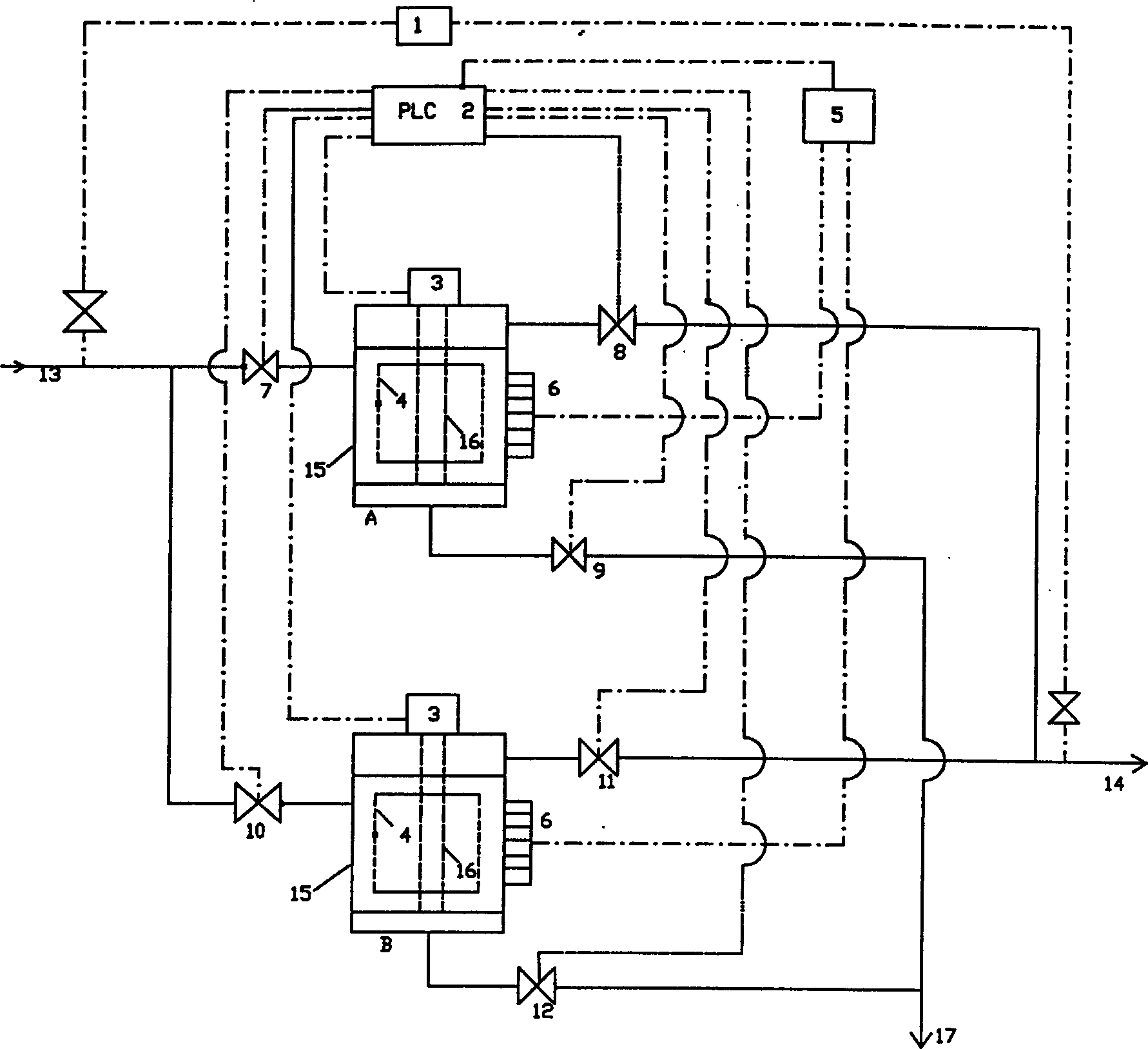

[0013] Shown in Fig. 3, a kind of on-line ultrasonic cleaning filtering device is characterized in that it consists of a plurality of filters with ultrasonic transducers 6, ultrasonic sounder 5, differential pressure transmitter 1, PLC automatic control device 2 and Corresponding process pipelines and control valves are connected. Depend on Figure 1-2 Shown, a plurality of filters that are equipped with ultrasonic transducers, it consists of a filter cylinder 15, a hollow shaft 16, a drum filter 4 that can rotate around the hollow shaft, a geared motor mechanism 3, at least one Composed of ultrasonic transducers 6; a plurality of ultrasonic transducers are fixed longitudinally in a row on the filter cylinder 15, and the hollow rotating shaft 16 is connected with the geared motor mechanism 3.

[0014] In the embodiment of the present invention, as shown in FIG. 3 , A and B are two filters, and each filter has two states of running and cleaning. The PLC automatic control devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com