Fuel pump

A fuel pump and fuel technology, which is applied in the direction of pumps, liquid fuel feeders, liquid fuel engines, etc., can solve problems such as fuel pump noise and fuel pump vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] (first embodiment)

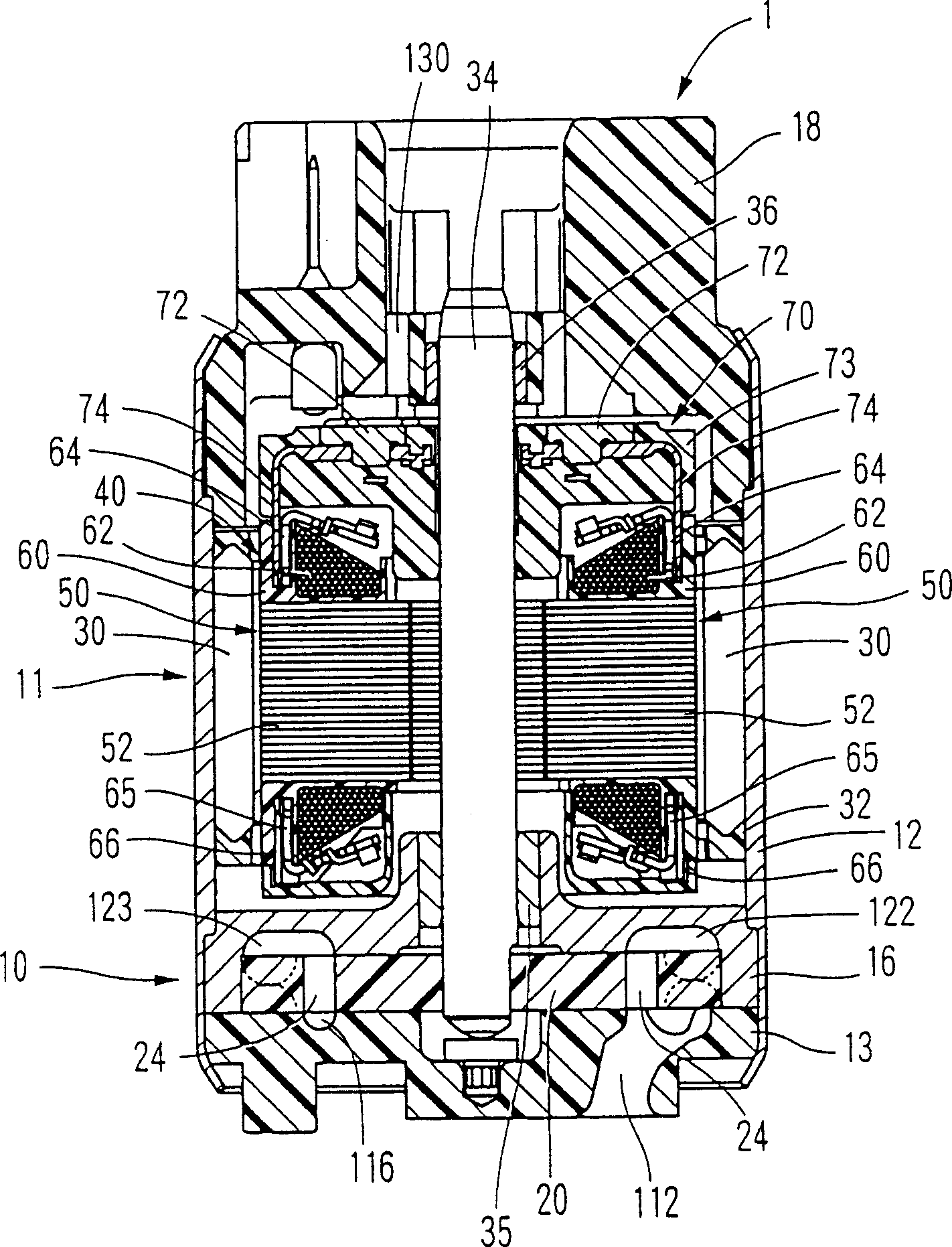

[0033] will now refer to figure 1 The fuel pump 1 according to the first embodiment is explained. The fuel pump 1 may be, for example, an in-tank type pump installed inside a fuel tank for a vehicle. The fuel pump 1 has a pump part 10 and a motor part 11 which is an electric motor.

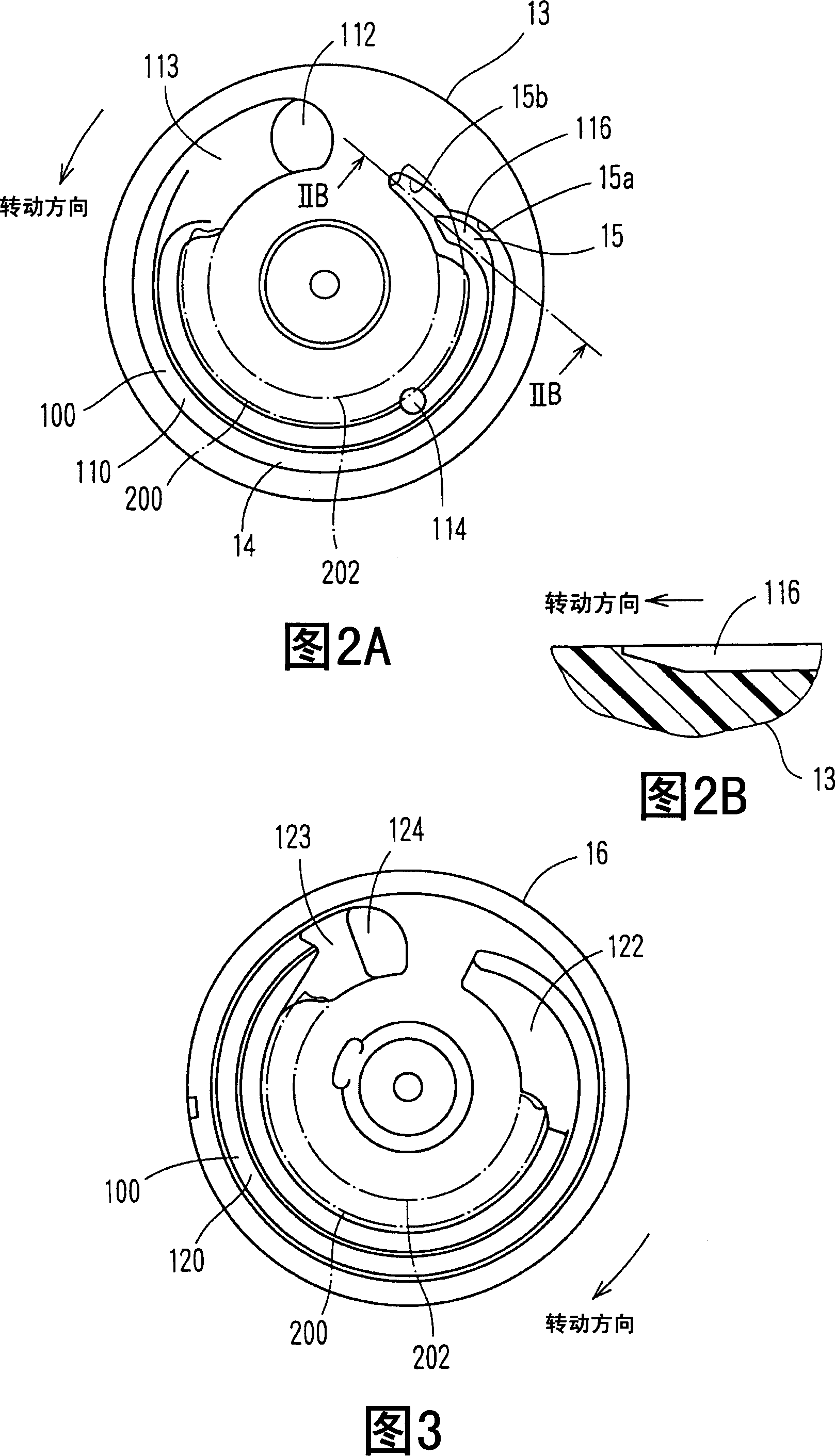

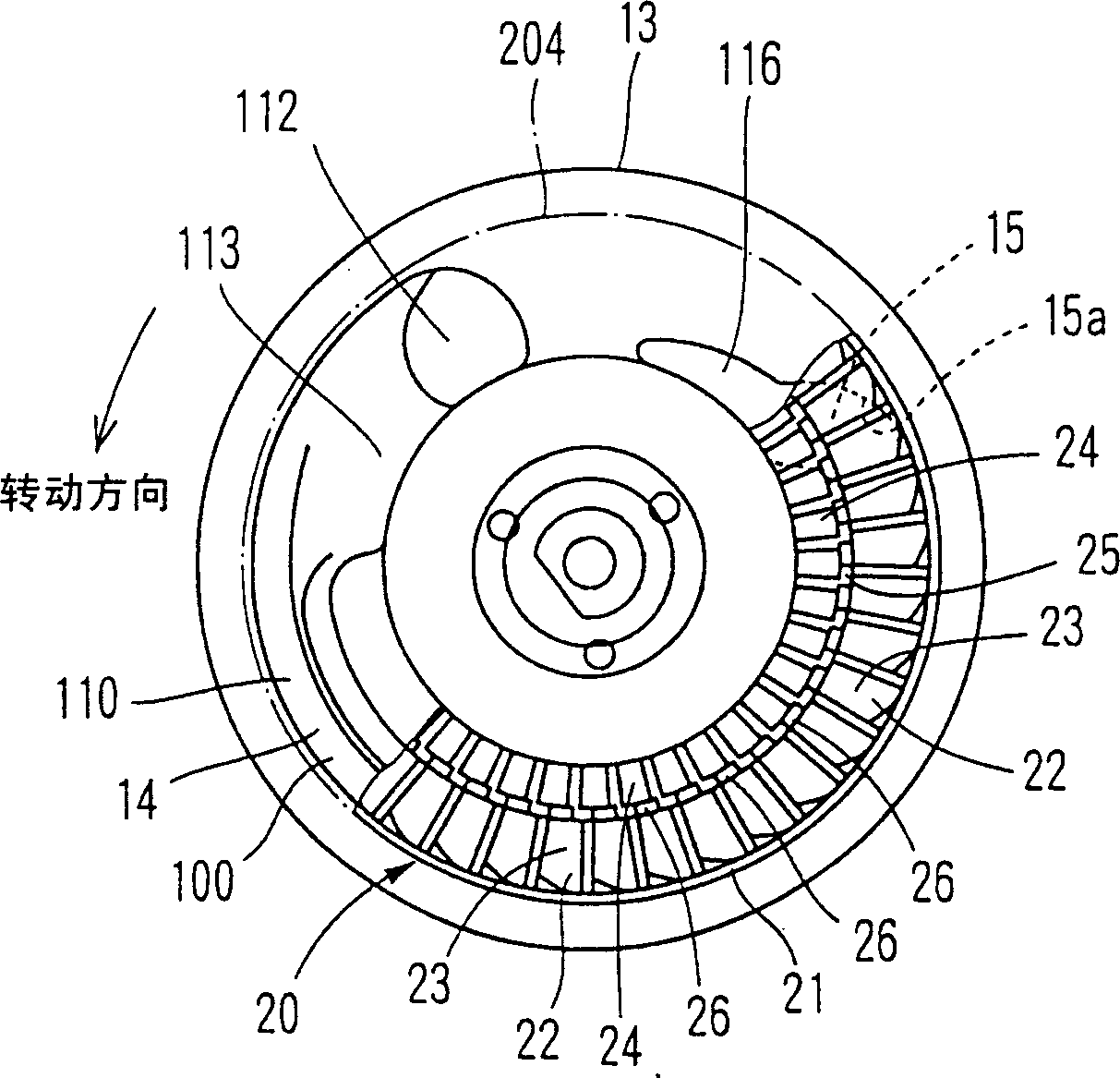

[0034]The pump section 10 includes a suction side cover 13 , a pump casing 16 and an impeller 20 . The pump casing 16 and the suction-side end cover 13 are fixed to the lower end portion of the housing 12 and are in a state that the pump casing 16 enclosing the impeller 20 at its lower inner peripheral portion is accommodated and sandwiched between the suction-side end in the axial direction. Between the cover 13 and the housing 12. The bearing member 35 is held by the upper portion of the inner circumference of the pump housing 16 . The suction side cover 13 and the pump casing 16 constitute a casing member that rotatably accommodates the impeller 20, a rotating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com