Reciprocating type high-pressure plunger pump for oilfield exploitation water treatment

A technology of high-pressure plunger pumps and exploiting water, which is applied in variable capacity pump parts, parts of pumping devices for elastic fluids, pumps, etc., and can solve inconvenient use, equipment damage, and inability to deal with shock absorption of equipment, etc. Problems, to achieve the effect of multiple functions, easy to disassemble or install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

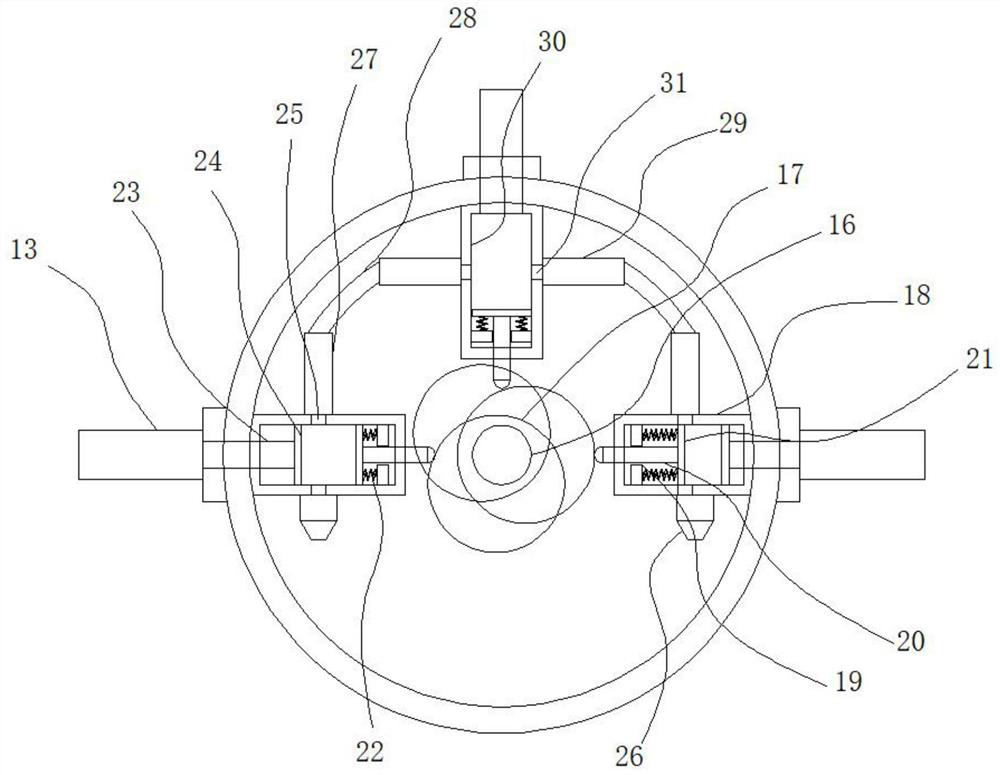

[0029] As a preferred embodiment of the present invention, a movable plate 24 is installed inside the pressurized chamber 18, a movable rod 23 is mounted on the movable plate 24, and one end of the movable rod 23 is mounted on the electric push rod 10 , A sealing ring is installed between the movable plate 24 and the inner wall of the pressurized chamber 18 .

[0030] As a preferred embodiment of the present invention, the top of the pressurized chamber 18 is provided with a water outlet 25, and a pipe 27 is installed on the water outlet 25, and a connecting pipe 28 is installed on the pipe 27. One end of connecting pipe 28 is fixed with pipeline two 29.

[0031] As a preferred embodiment of the present invention, a drain cavity 30 is installed at the bottom of the outlet pipe 9, and the drain cavity 30 is fixed on the inner wall of the working part 7, and a piston and a movable piston are installed inside the drain cavity 30. Column one, the drainage chamber 30 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com