Power tool

A power tool, reciprocating motion technology, applied in striking tools, manufacturing tools, lightweight impact tools, etc., can solve the problems of complex structure and assembly operations, increase the weight of the electric hammer, damage the appearance of the electric hammer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

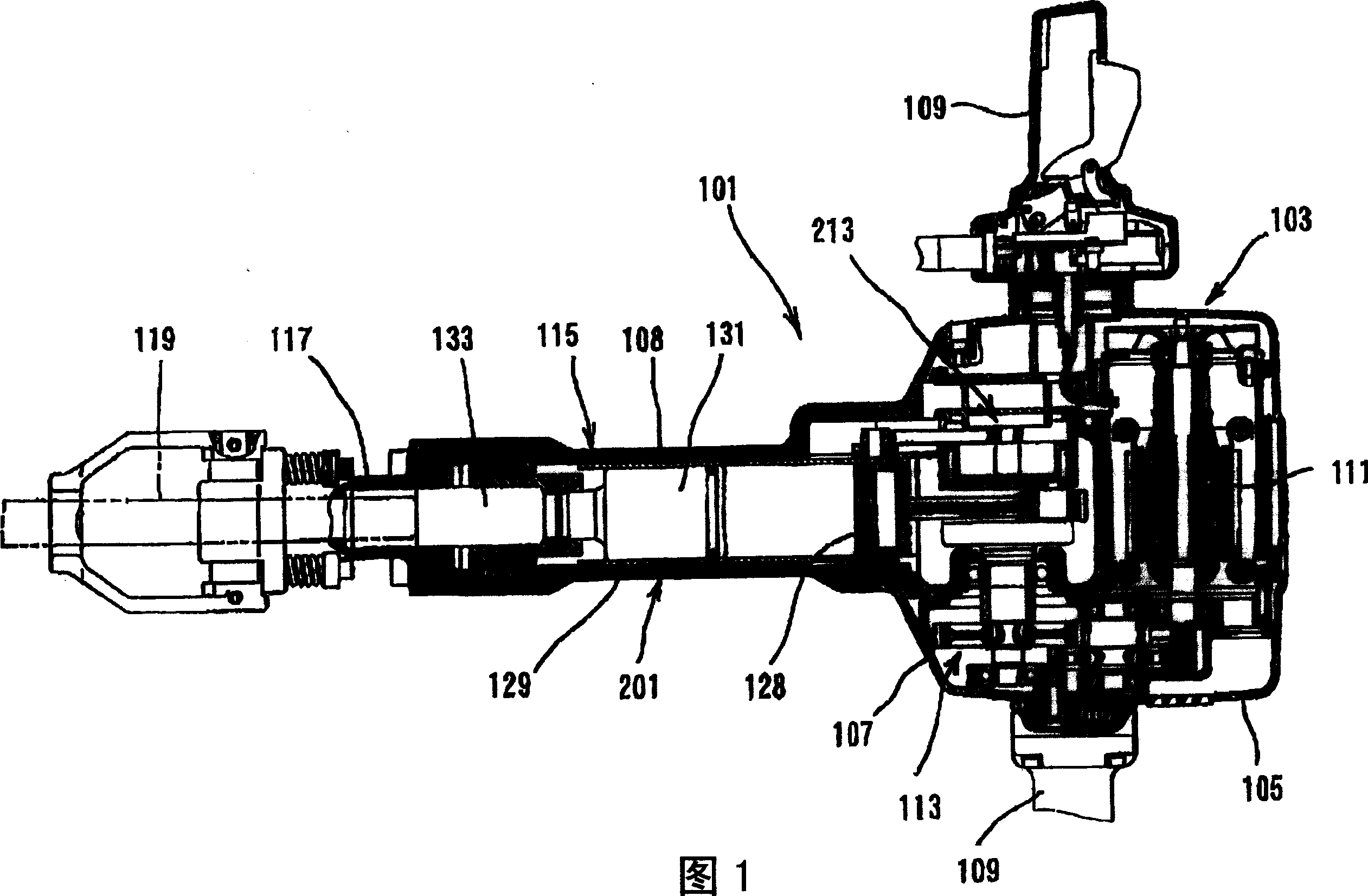

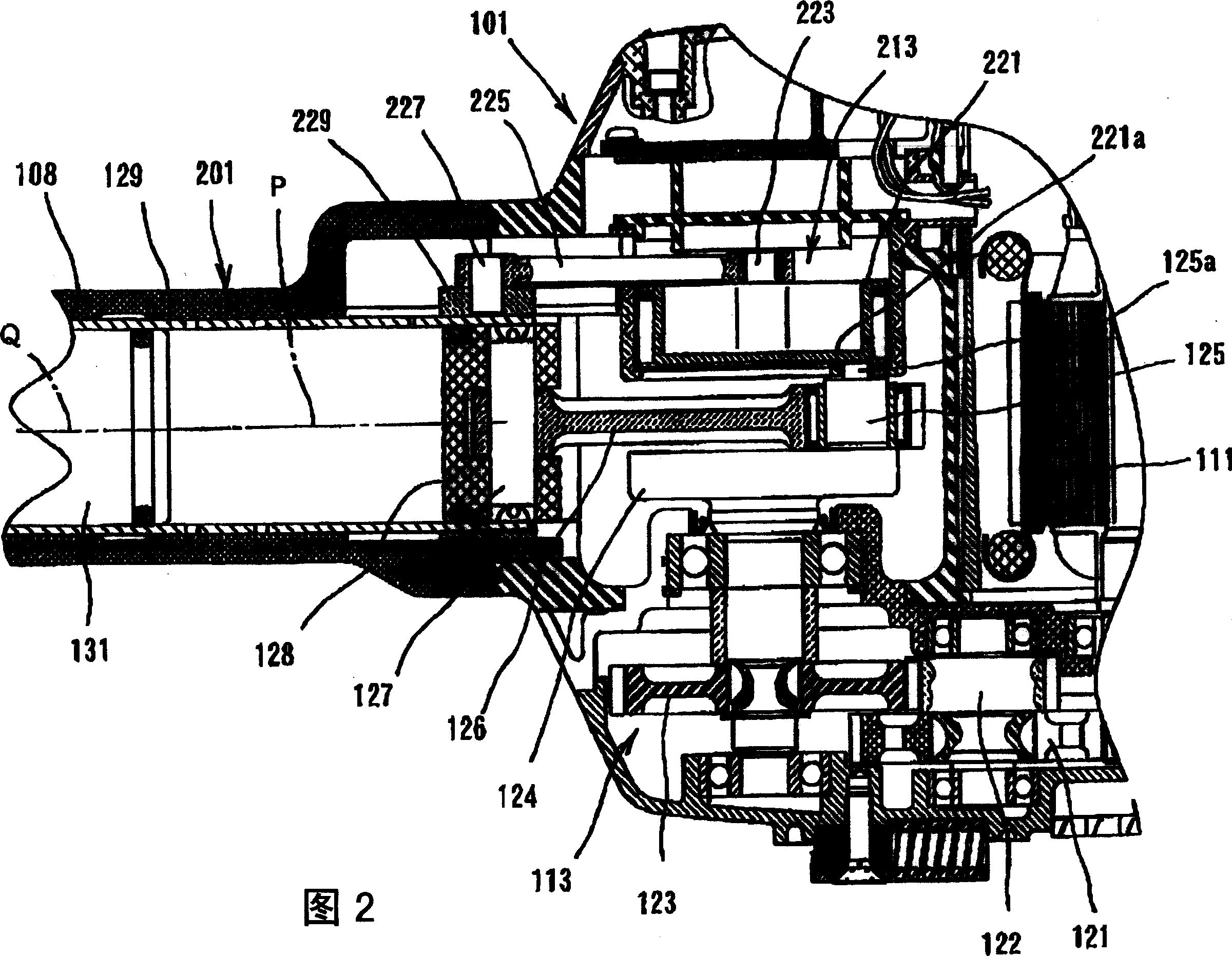

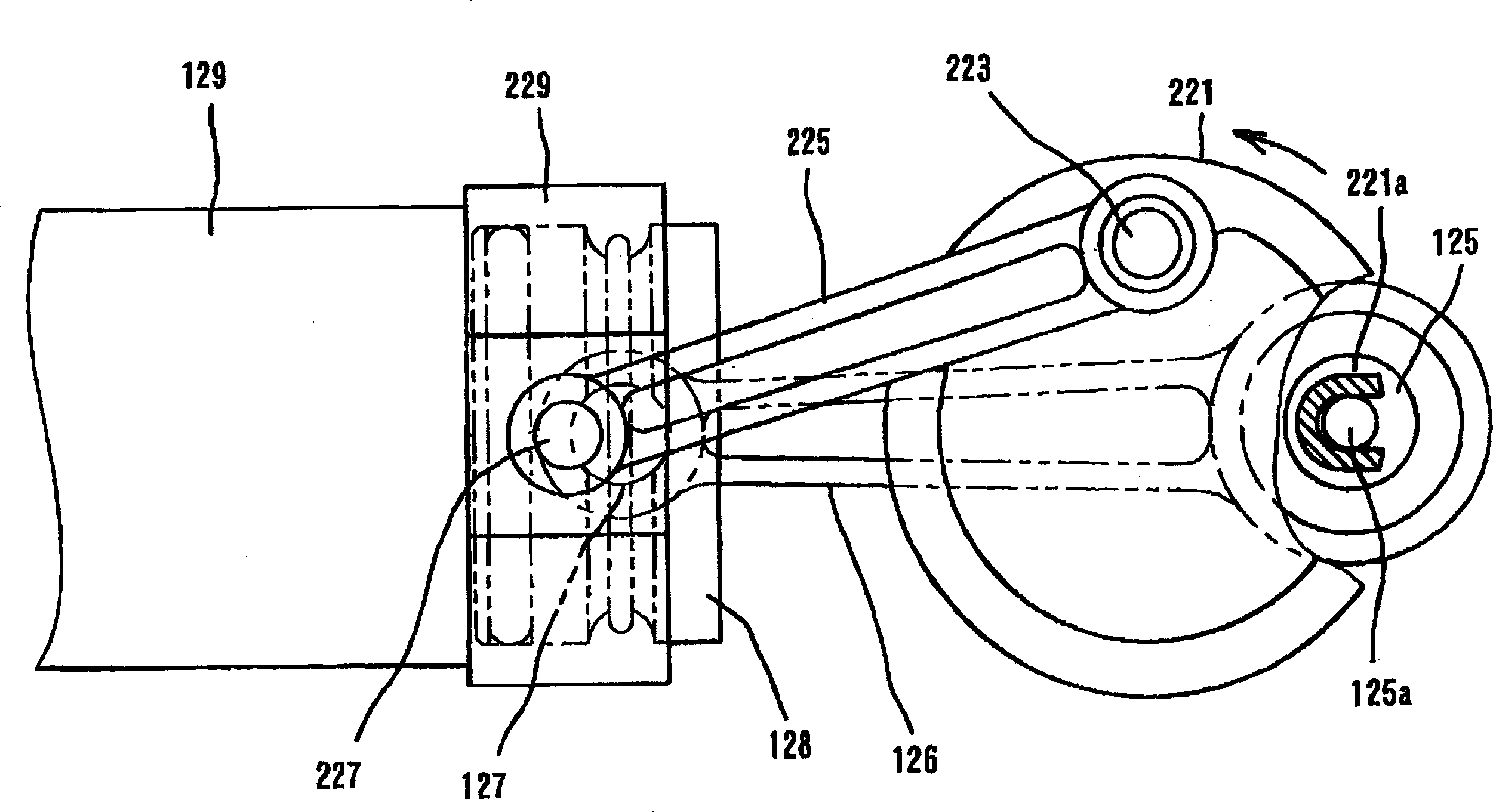

[0028] According to the present invention, a representative power tool includes: a hammer, a bit and a shock absorber. The hammer reciprocates under the action of air pressure fluctuations in the cylinder. The hammer can directly strike the cutter head under the action of the air pressure fluctuation in the cylinder. Alternatively, the air pressure fluctuations in the cylinder drive the hammer to hit another impact force transmission element such as an impact bolt, and then the impact force transmission element impacts the cutter head. The cutting head performs a predetermined operation under the impact force of the hammer. The shock absorber reduces shock on the ram by reciprocating in a direction opposite to that of the ram. The trajectory of the center of gravity of the shock absorber is designed to coincide with the trajectory of the center of gravity of the hammer. With this configuration, since no rotational (turning) moment is applied to the reciprocating cylinder du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com