A cascade mechanism in laser processing process

A tandem mechanism and laser processing technology, applied in laser welding equipment, metal processing equipment, manipulators, etc., can solve the problems of large space occupation, increased number of lenses, high laser energy loss, etc., and achieve small space occupation and space structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

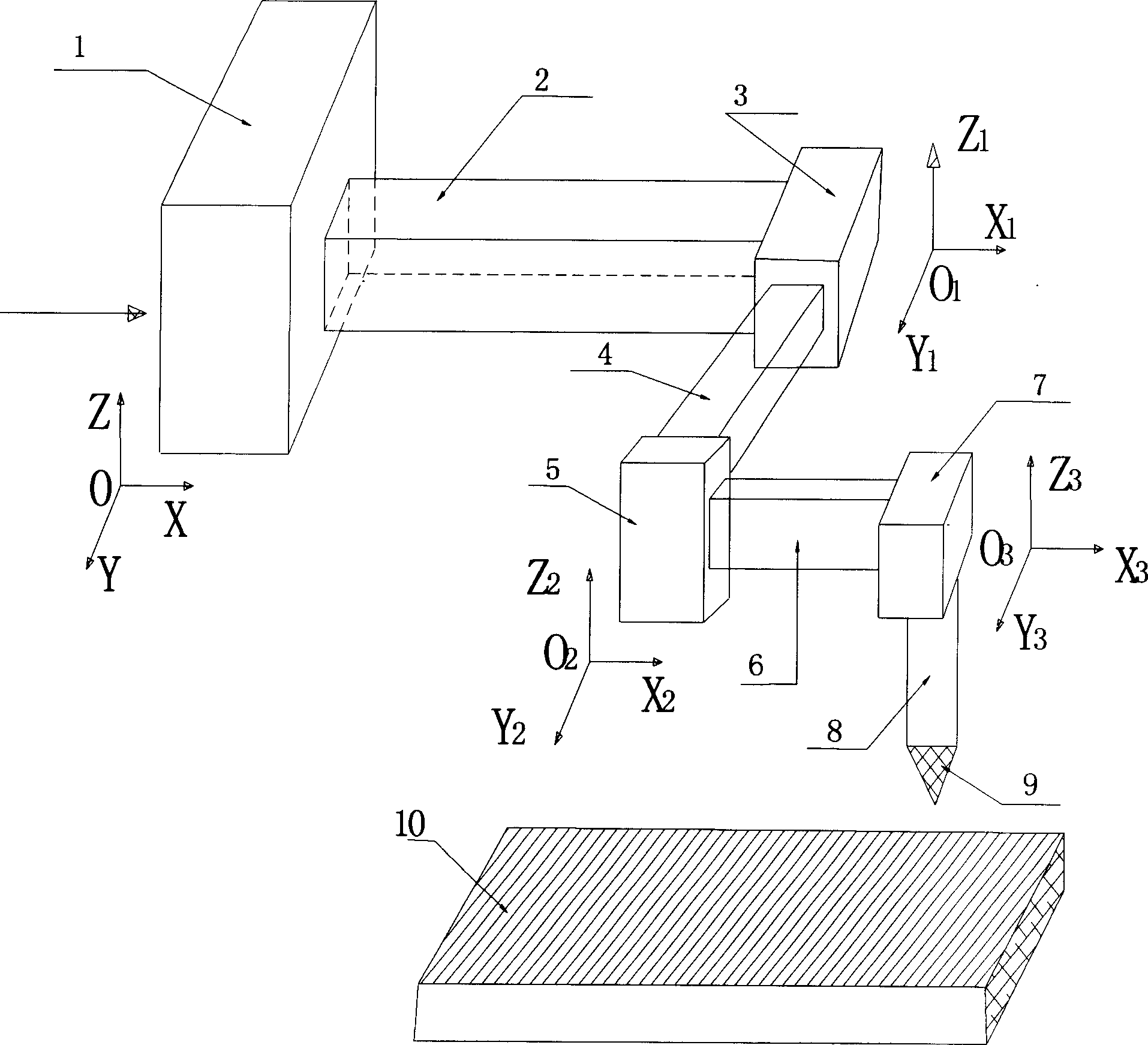

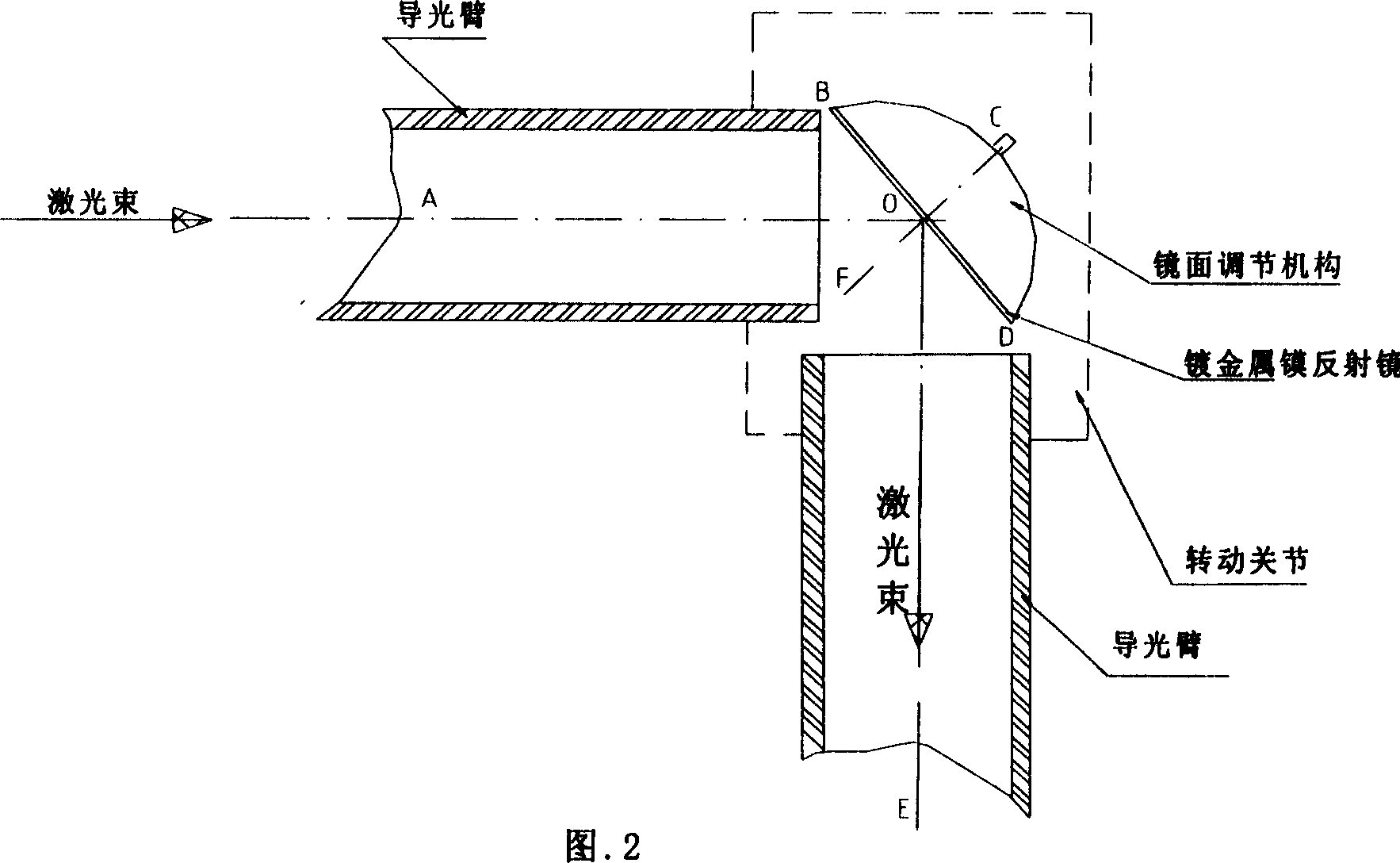

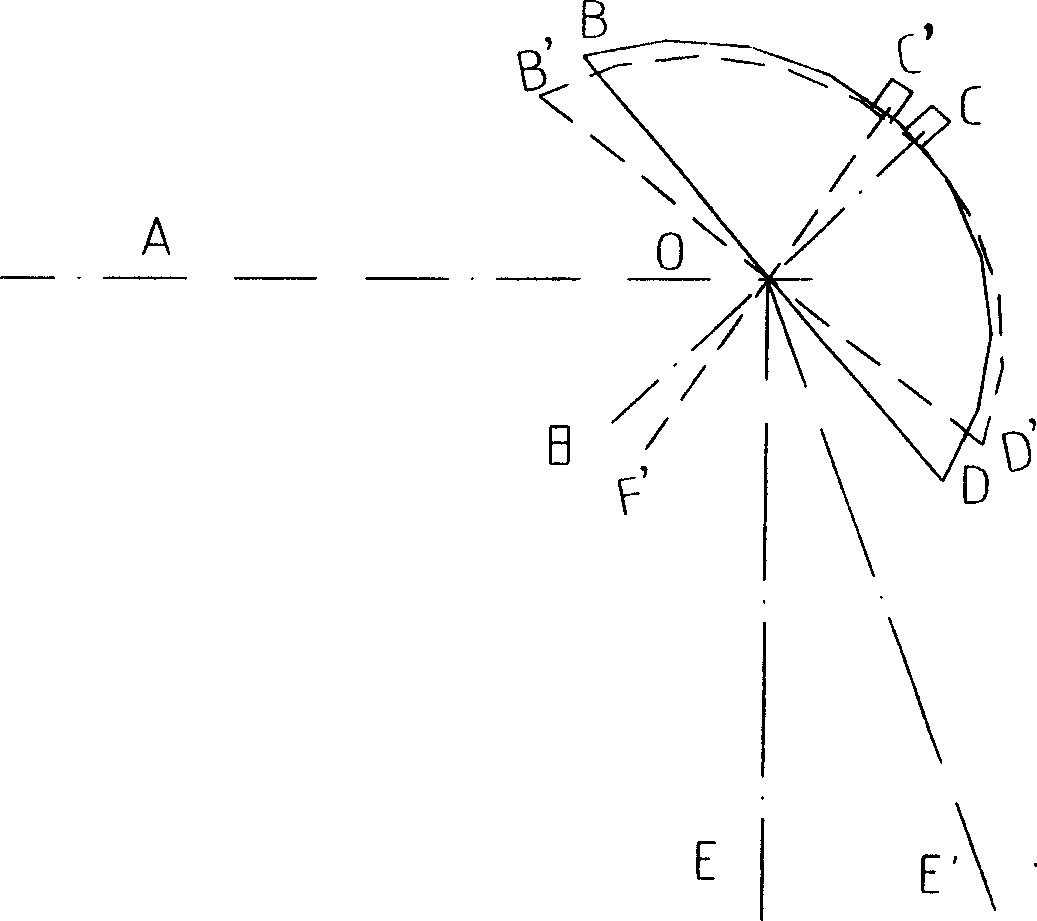

[0011] exist figure 1 Among them, in order to clarify the relative relationship between the various structural components of the embodiment, four mutually parallel spatial coordinate systems are established, as shown in the figure OXYZ, O 1 x 1 Y 1 Z 1 , O 2 x 2 Y 2 Z 2 , O 3 x 3 Y 3 Z 3 ; The fixed platform frame (1) is fixedly connected with the light guide arm one (2), and the laser beam from the laser generator directly enters the first light guide arm through the light guide device of the fixed platform frame (1)—the light guide arm one (2); light guide arm one (2) is connected with light guide arm two (4) through swivel joint one (3), and swivel joint one (3) rotates and drives light guide arm two (4) in O 1 x 1 Y 1 In-plane around Z 1 The shaft rotates; the second light guide arm (4) is connected with the third light guide arm (6) through the second rotary joint (5), and the second rotary joint (5) rotates to drive the third light guide arm (6) to rotate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com