Plant macadam pavement and its construction method

A construction method, a technology of crushed stone, applied in the directions of botanical equipment and methods, roads, roads, etc., can solve the problems of reducing the comfort of urban life, increasing the heat of urban summer, increasing energy consumption, etc., achieving simple structure, low cost, The effect of fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

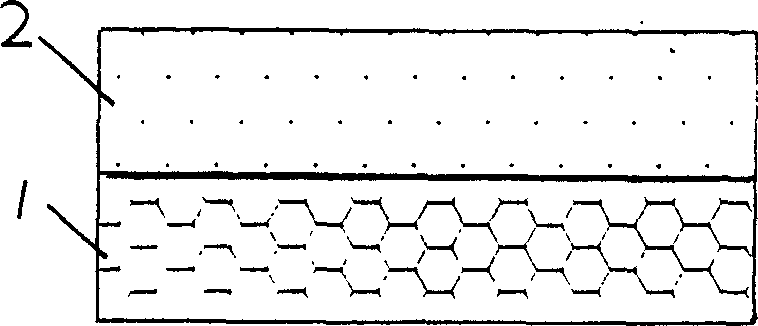

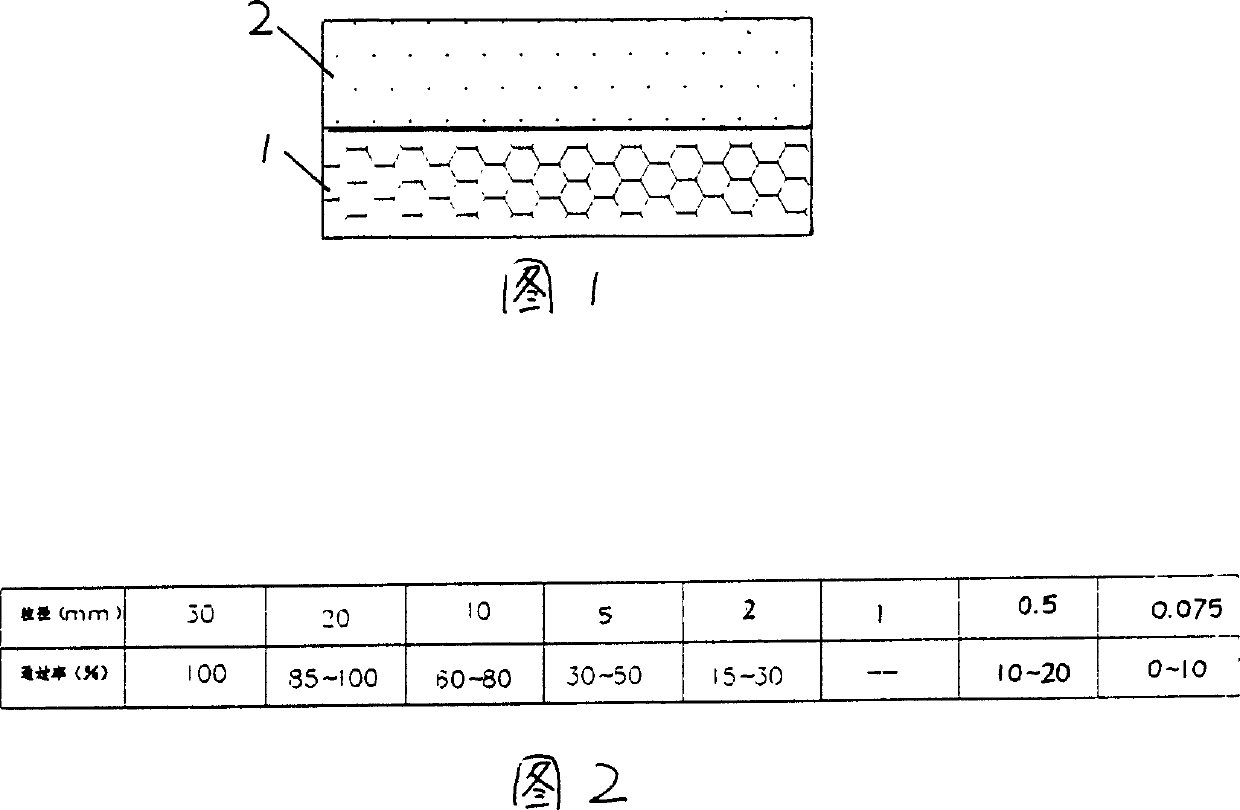

[0013] The construction method of the plant crushed stone pavement comprises the following steps: a. laying a graded crushed stone layer with a thickness of 20 centimeters; Good material; c, be 10% by weight percentage and prepare the planting soil mixture, wherein the planting soil mixture contains 20% organic fertilizer; d, mix the prepared gravel and the planting soil mixture, and carry out Test the sprinkling water so that its water content is 9.8%; e, transport the evenly mixed mixture to the site, and pave it with a paver or a grader, and the paving thickness is 25 cm; f, the spreading weight percentage is 0.2% Hound 5# grass seed; g, rolling with 8 tons of road rollers, the degree of compaction is 90%, and the thickness after compaction is 20 cm; h, through sprinkling and maintenance until the grass seed germinates.

Embodiment 2

[0015] The construction method of plant crushed stone pavement comprises the following steps: a, laying a graded crushed stone layer according to a thickness of 25 centimeters; Good material; c, be 8% by weight percentage and prepare the planting soil mixture, wherein the planting soil mixture contains 15% organic fertilizer; D, mix the prepared crushed stone and planting soil mixture, and carry out Sprinkle water and test to make the water content 8.5%; e, transport the evenly mixed mixture to the site, and pave it with a paver or a grader, and the paving thickness is 25 cm; f, the weight percentage of spreading is 0.5% g, rolling with a 7-ton road roller, the degree of compaction is 95%, and the thickness after compaction is 15 cm; h, through watering and maintenance until the grass seeds germinate.

Embodiment 3

[0017] The construction method of plant crushed stone pavement comprises the following steps: a. laying a graded crushed stone layer according to a thickness of 15 centimeters; C, be 9% by weight percentage and prepare the planting soil mixture, wherein the planting soil mixture contains 10% organic compound fertilizer; D, mix the prepared gravel material and the planting soil mixture, and carry out Test the sprinkling water so that its water content is 5.8%; e, transport the evenly mixed mixture to the site, use a paver or a grader to pave, and the paving thickness is 25 cm; f, spread the weight percentage of 0.2% Bagengrass grass seeds; g, rolling with an 8-ton road roller, the degree of compaction is 90%, and the thickness after compaction is 10 cm; h, watering and curing until the grass seeds germinate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com