Motor control device and method

A technology of motor control and control pair, which is used in motor control, electronic commutation motor control, DC motor speed/torque control, etc., and can solve problems such as inability to input and respond, inability to estimate rotor position, and shortening of pulse width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

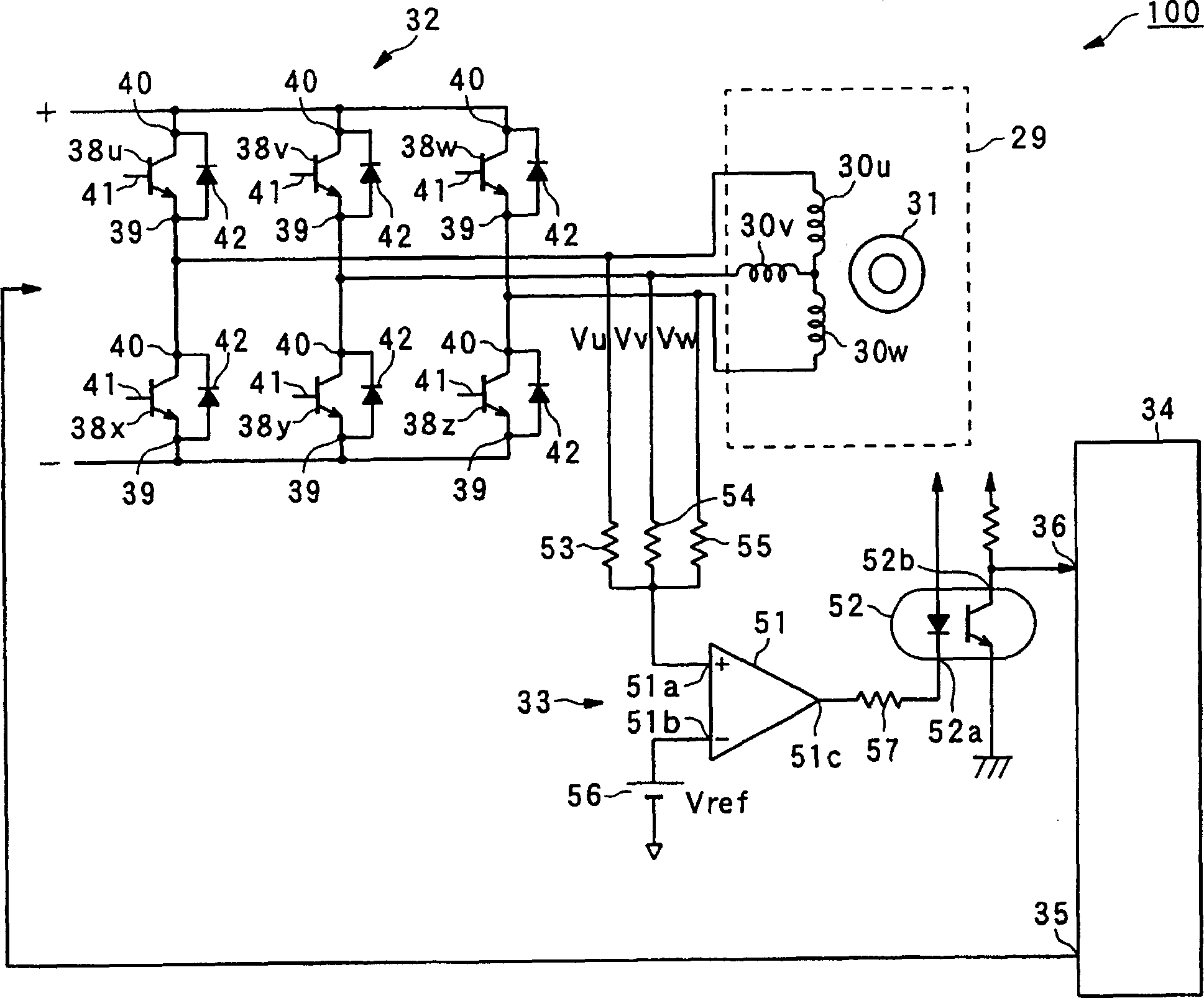

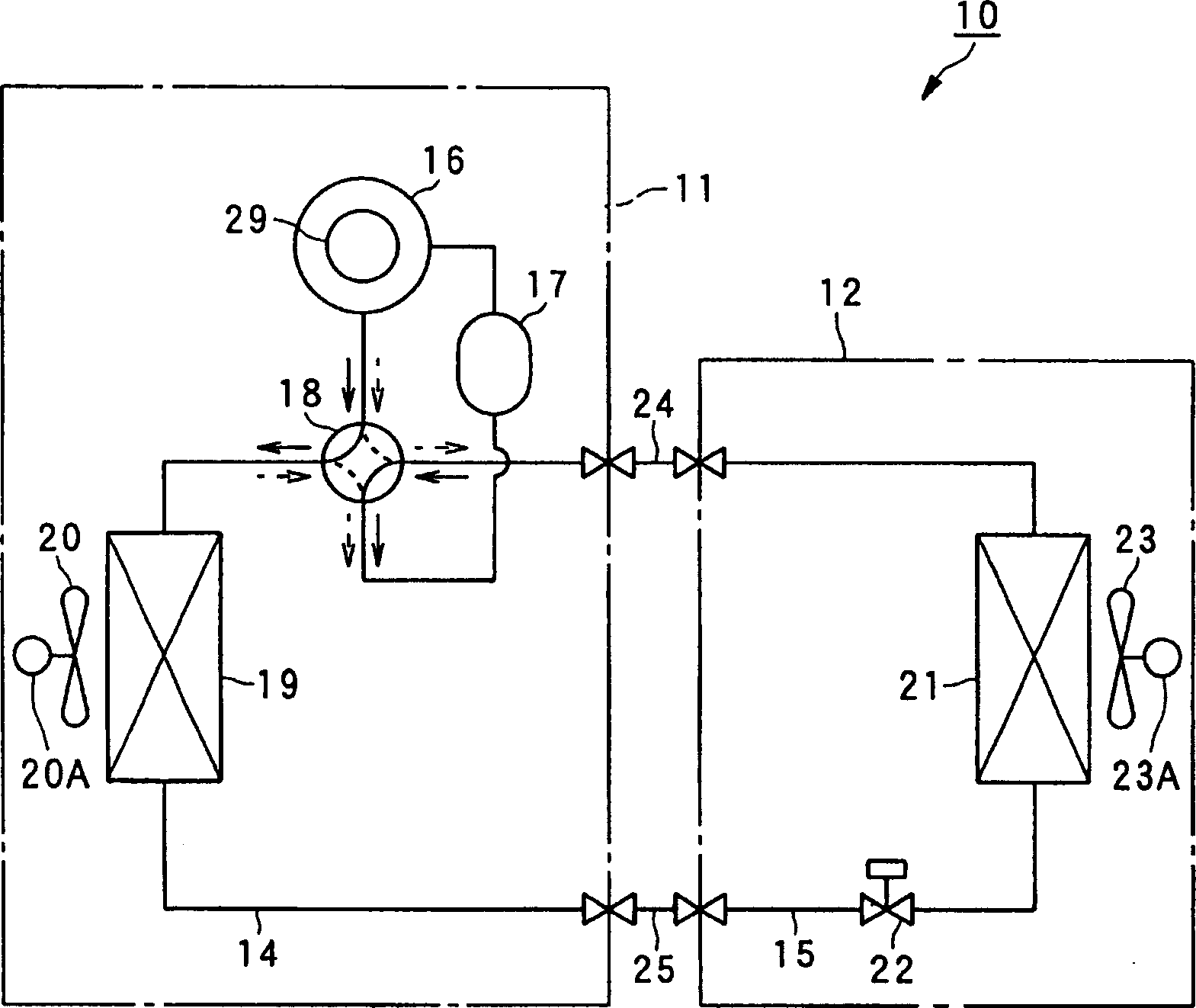

Method used

Image

Examples

no. 2 Embodiment approach

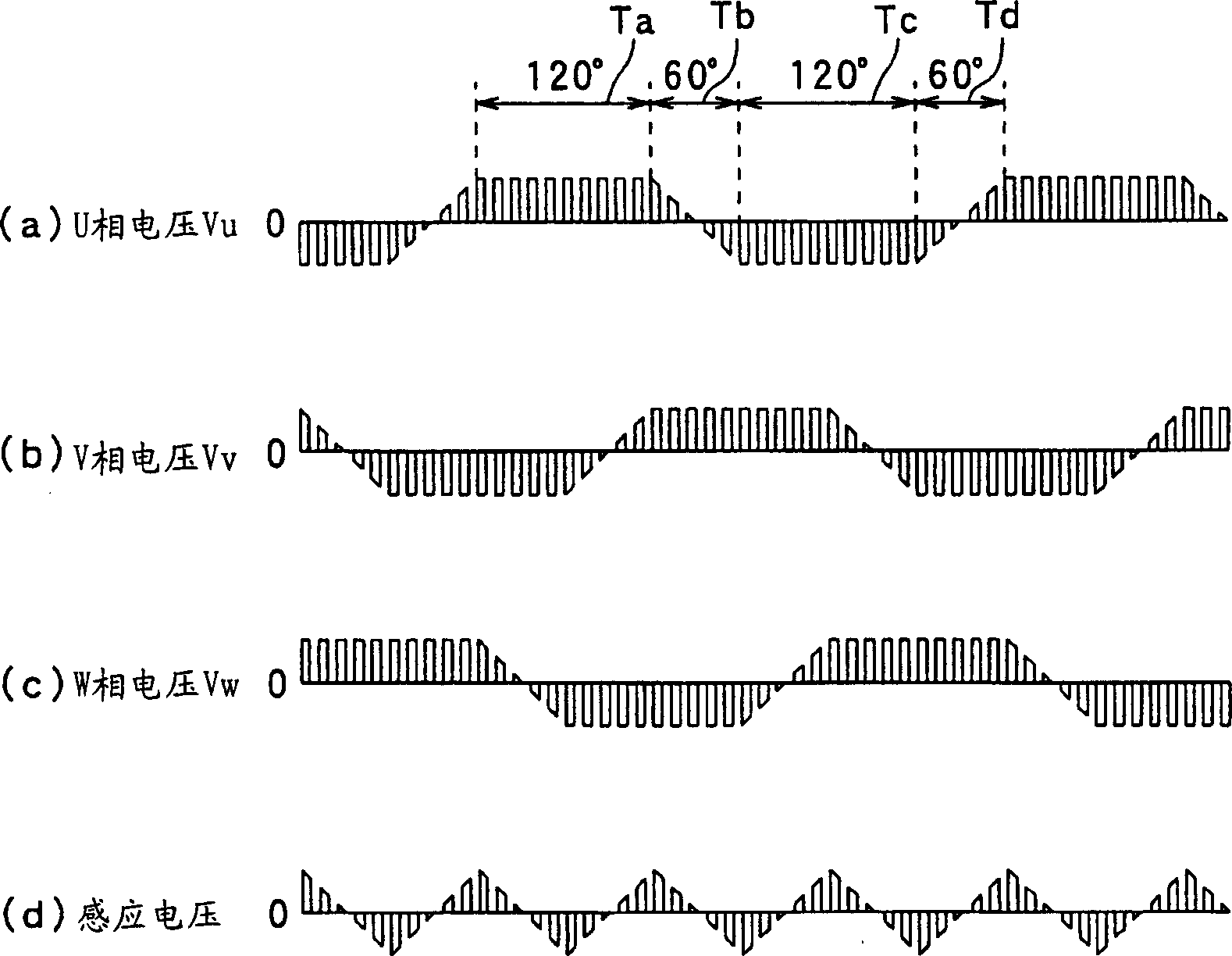

[0061] In the above-mentioned first embodiment, a case was described in which the control unit 34 continuously lowers the carrier frequency B as the duty ratio decreases. The carrier frequency is stepped down. Furthermore, the configuration of the system is the same as that of the first embodiment figure 1 with figure 2 are the same, and therefore descriptions are omitted.

[0062] Figure 5 It is an explanatory diagram showing the carrier frequency corresponding to the duty ratio.

[0063] First, with the first embodiment Figure 4 Similarly, the control unit 34 sets the threshold value A (for example, 5 [%]) according to the duty ratio of the PWM switching signal.

[0064] Then, the control unit 34 lowers the carrier frequency B' stepwise as the duty ratio decreases so that the PWM with a duty ratio corresponding to the applied voltage (line voltage or phase voltage) C of the brushless DC motor 29 is generated. When switching signals, when the duty ratio of the PWM sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com