Multifunctional high power machine for earthworker's cloth testing and use thereof

A geotextile and multi-functional technology, applied in the direction of applying stable tension/compression to test the strength of materials, can solve the problems of uneven stress on geotextiles, affecting test results, laborious and laborious, etc., and achieve a wide range of test items and testing Accurate data and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

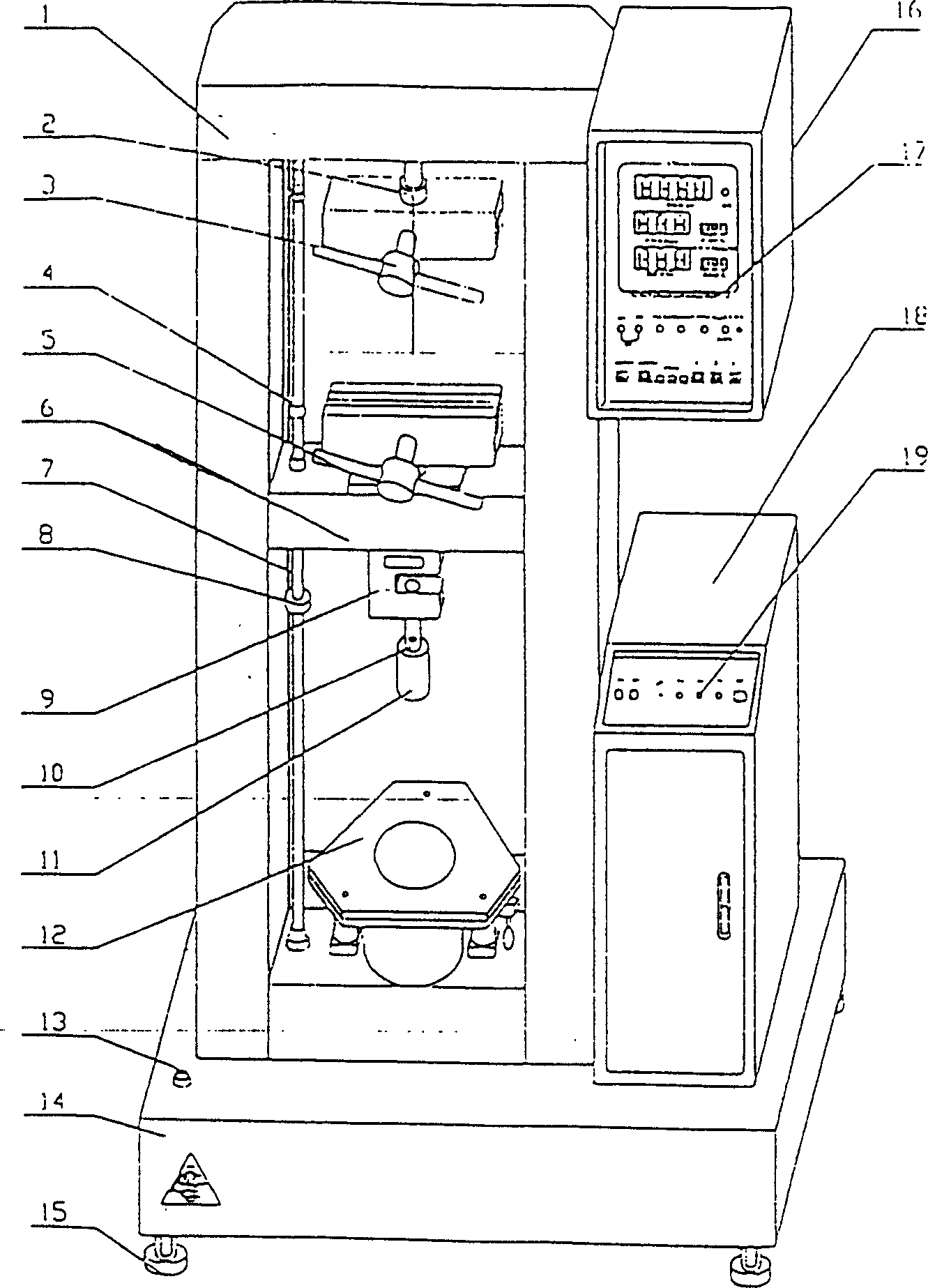

[0046] Example 1: Structure as figure 1 , 2 , 10, it is composed of beam 6, power part, lifting clamping device 12, CBR bursting probe 22, probe base 10, sensor 9, microcomputer control device 16, display device 17, door frame 1 and base 23 Among them, the base 23 is provided with four adjustable feet 15, the clamping device 12 is in the door frame 1, the upper part of the inner side of the door frame 1 is connected to the upper clamp 3 through the upper connecting shaft 2 to stretch and tear, and stretch The tearing lower gripper 5 is set on the upper part of the beam 6, the two ends of the beam 6 are connected to the power part, the beam 6 can move up and down in the mast 1, the lower part of the beam 6 is provided with a 30KN sensor 9, and a measuring device is connected below. Head seat 10. The lifting clamping device 12 is clamped by the pneumatic part. The lifting clamping device 12 is composed of a lower fixed part, an upper movable part, a cylinder and a valve. The lower ...

Embodiment 2

[0048] Example 2: Structure as image 3 As shown, when the ball burst test is performed, a 3KN sensor 11 is connected with a pin on the probe base 10. The lower end of the 3KN sensor 11 has a connecting wire hole, and the ball burst probe 20 is connected to the 3KN sensor 11 through a thread In the connecting wire hole, the other structure and work are the same as in Example 1.

Embodiment 3

[0049] Example 3: Structure as Figure 4 As shown, when doing a puncture test, connect a 3KN sensor 11 with a pin on the probe base 10. The lower end of the 3KN sensor 11 has a connecting wire hole, and the puncture probe 21 is connected to the connecting wire hole of the 3KN sensor 11 through a thread Inside, the other structure and work are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com