Process method for testing microbe in stored unpackaged cropper

A technology for microorganisms and crops, which is applied in the field of detection and treatment of microorganisms in the storage process of bulk crops. It can solve the problems of mildew, large energy consumption, and long working hours, etc., and achieves inhibition of biological growth, uniform wind network layout, and solution The effect of ventilation and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

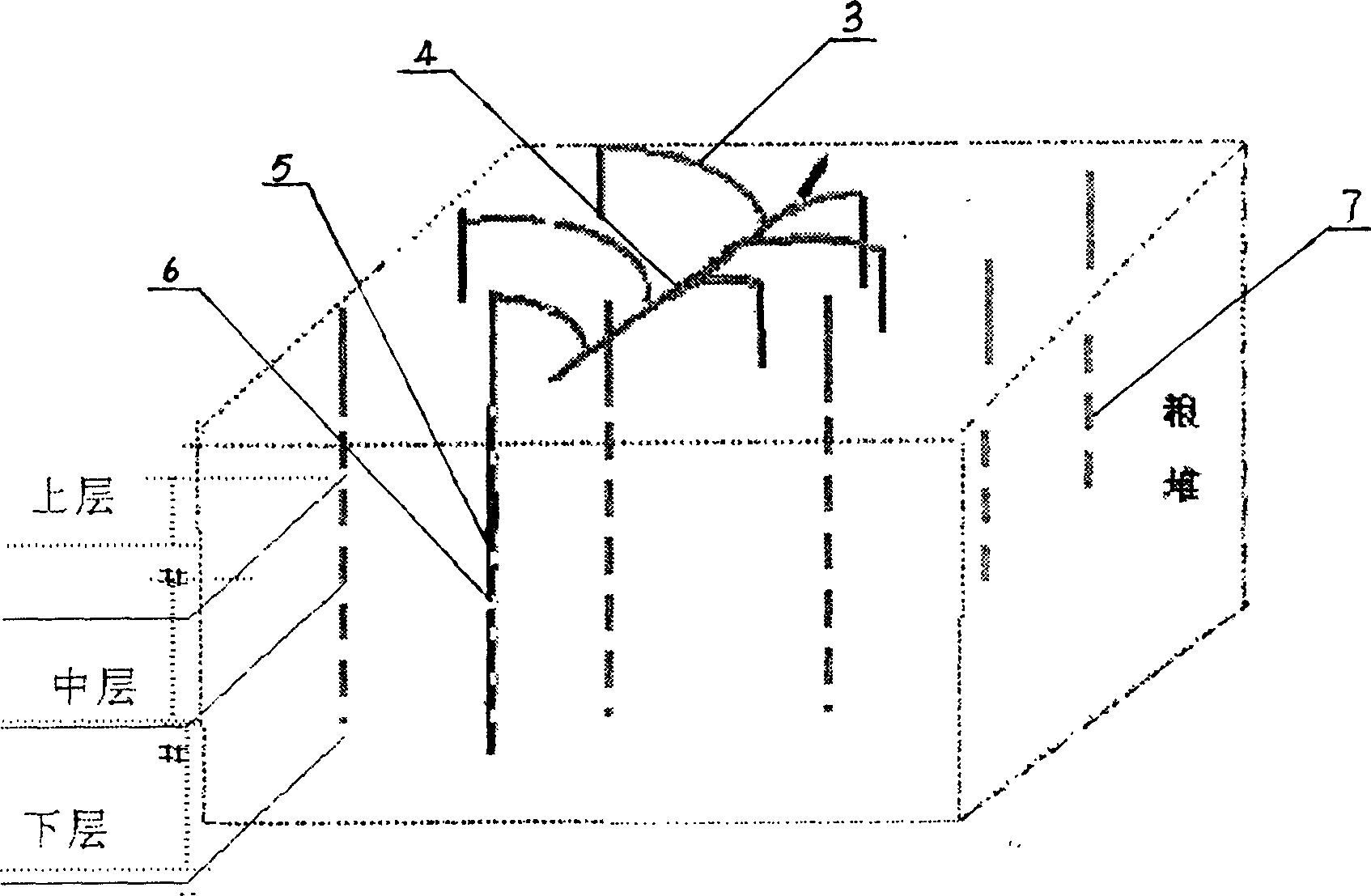

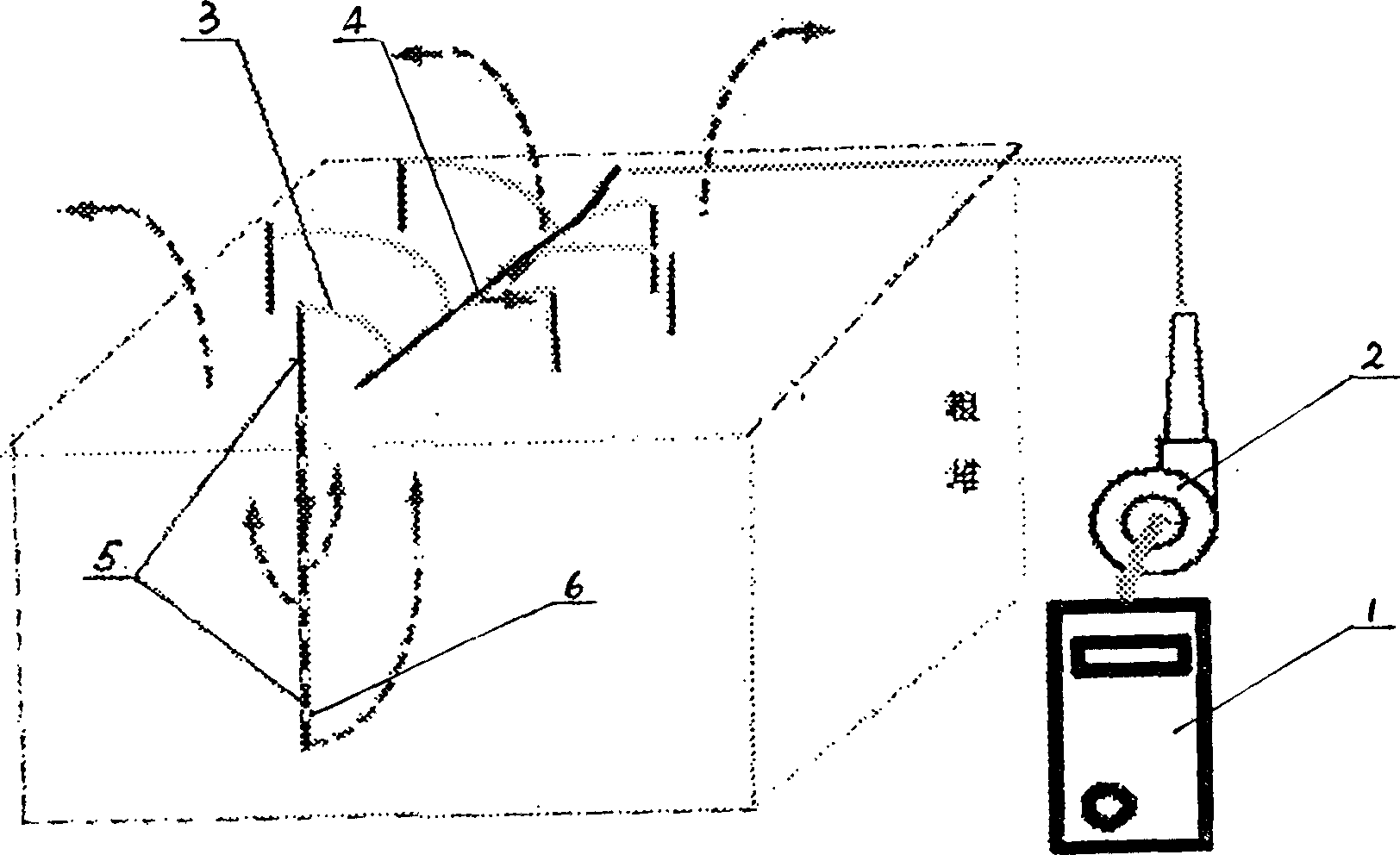

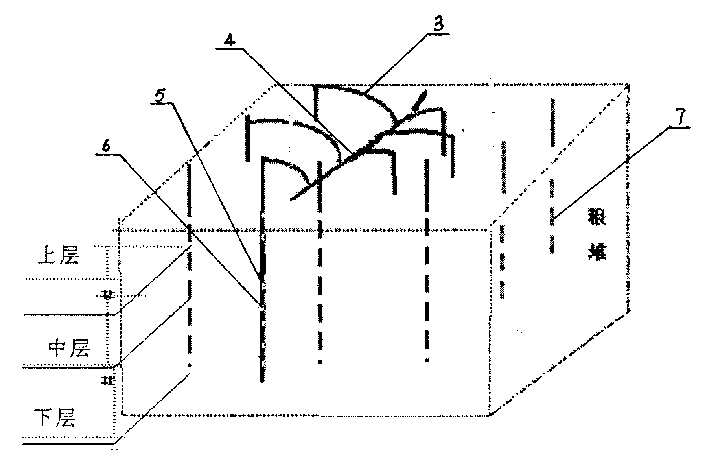

[0030] Embodiment 1: (storage agricultural crop is Jiangxi paddy sample)

[0031] The present invention arranges 7 points per 10 square meters, and after the fixed-point sampling is carried out with the sampling device 7 from the upper, middle and lower layers, the rapid microbial detection instrument is used to analyze, detect and judge, and finally use a multi-functional processing device to detect and judge when the over-standard The sample point of the sample was treated with ozone; again, it was analyzed and judged by the rapid microbial detector, and the above steps were repeated until the microbial activity of the sample sample was below 200 activity units. A total of 21 samples were taken this time.

[0032] The upper layer sampling point of the present invention refers to that the distance from the sampler probe 7 to the crop pile surface is 40 centimeters.

[0033] The lower sampling point of the present invention refers to that the distance from the sampler probe 7...

Embodiment 2

[0044] Embodiment 2: (the crops in the storage bin are rapeseed)

[0045] The present invention arranges 5 points per 10 square meters, and after the fixed-point sampling is carried out with the sampling device 7 from the upper, middle and lower three layers, the rapid microbial detection instrument is used to analyze, detect and judge, and finally use a multi-functional processing device to detect and judge when the over-standard The sample point of the sample was treated with ozone; again, it was analyzed and judged by the rapid microbial detector, and the above steps were repeated until the microbial activity of the sample sample was below 200 activity units. A total of 15 samples were taken this time.

[0046] The upper layer sampling point of the present invention refers to that the distance from the sampler probe 7 to the crop pile surface is 20 centimeters.

[0047] The lower sampling point of the present invention refers to that the distance from the sampler probe 7 t...

Embodiment 3

[0057] It can be seen from the above table that the total microbial activity and the number of mold spores in rapeseed treated with ozone are lower than those before treatment. Embodiment 3: (stored crops are tobacco)

[0058] The present invention arranges 5 points per 10 square meters, and after the fixed-point sampling is carried out with the sampling device 7 from the upper, middle and lower three layers, the rapid microbial detection instrument is used to analyze, detect and judge, and finally use a multi-functional processing device to detect and judge when the over-standard The sample point of the sample was treated with ozone; again, it was analyzed and judged by the rapid microbial detector, and the above steps were repeated until the microbial activity of the sample sample was below 150 activity units. A total of 15 samples were sampled this time.

[0059] The upper layer sampling point of the present invention refers to that the distance from the sampler probe 7 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com