Electromagnetic driver and exposure reglation component using it

A drive, electromagnetic technology, applied in the field of electromagnetic drive, exposure adjustment components, can solve the problem of increasing the volume of the magnet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

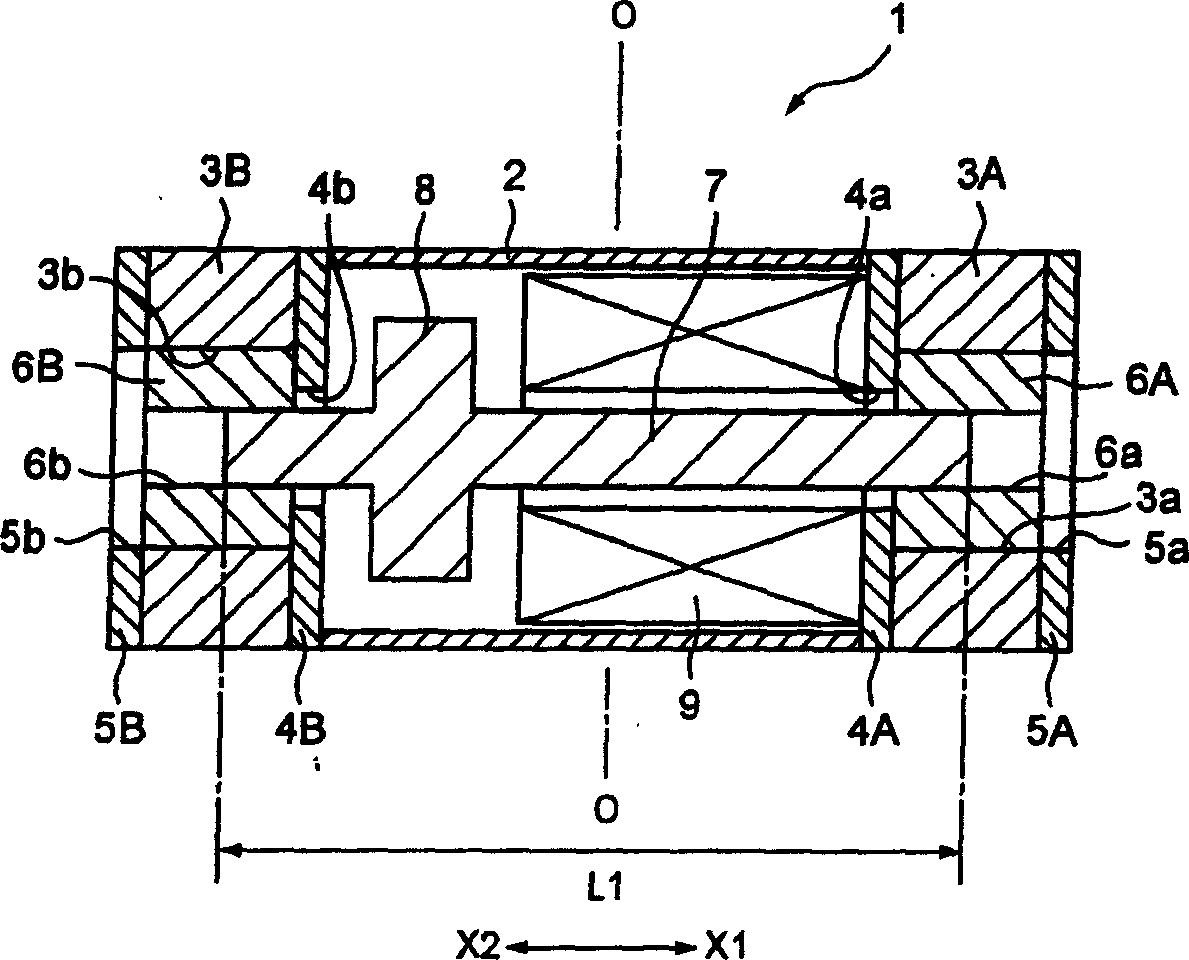

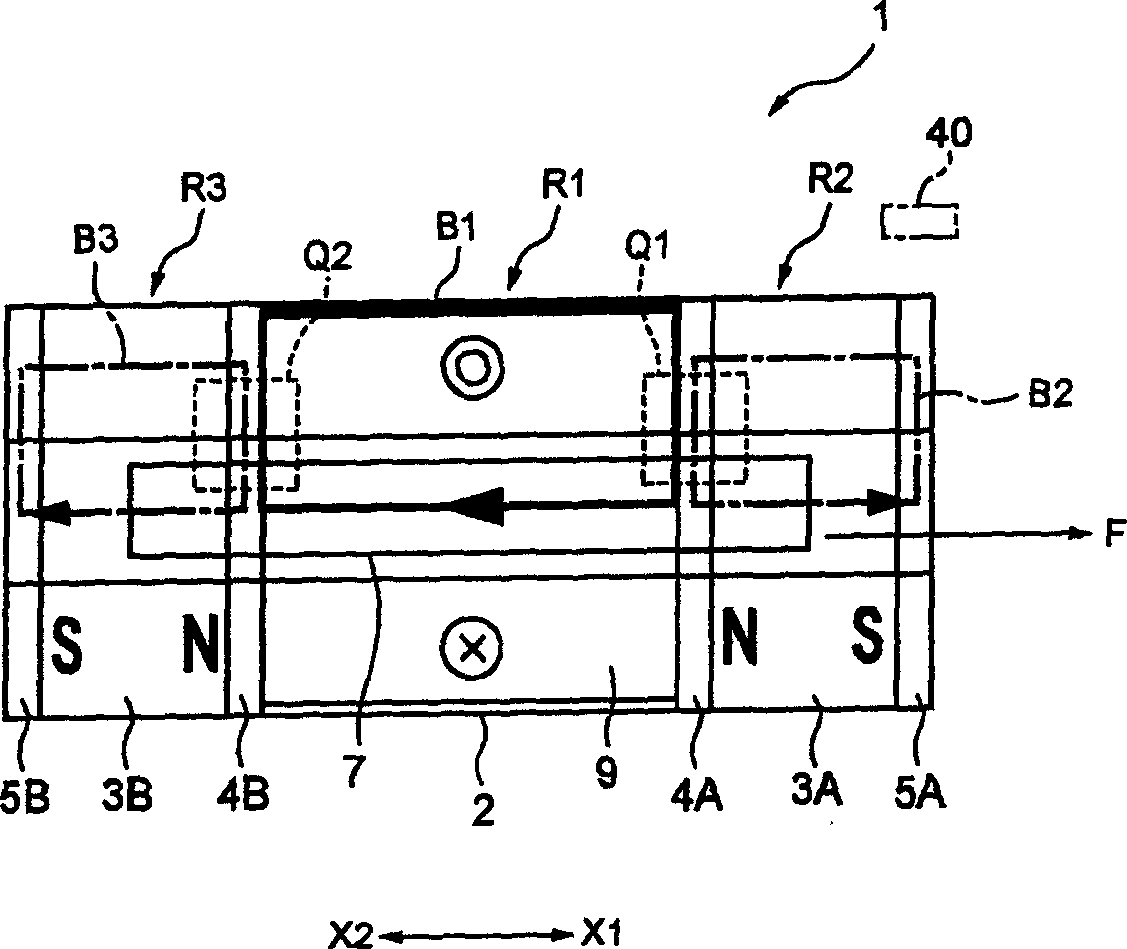

[0031] figure 1 Is a plan view showing an example of the appearance of the electromagnetic actuator of the present invention, figure 2 Is a cross-sectional view of the electromagnetic drive, image 3 It is a schematic diagram showing the flow of the magnetic field inside the electromagnetic actuator. Figure 4 It is a graph showing the relationship between the attractive force to the shaft and the amount of displacement, Figure 5 It is a graph showing the relationship between the driving force generated by the coil and the amount of displacement.

[0032] Such as figure 1 As shown, the electromagnetic actuator 1 of this embodiment has a cylindrical barrel 2. The cylinder 2 is made of magnetic materials such as iron or ferrite. In addition, the cylindrical body 2 is formed with a quadrangular opening 2a penetrating along its curved surface.

[0033] Such as figure 2 As shown, on the X1 side and X2 side of the cylinder 2, magnets 3A and 3B made of permanent magnets are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com