Rolling and friction composite testing machine

A technology of composite testing and friction parts, which is applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problems of oil pollution, high energy consumption, and small test pieces in the hydraulic system, and achieve simple and compact structure and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

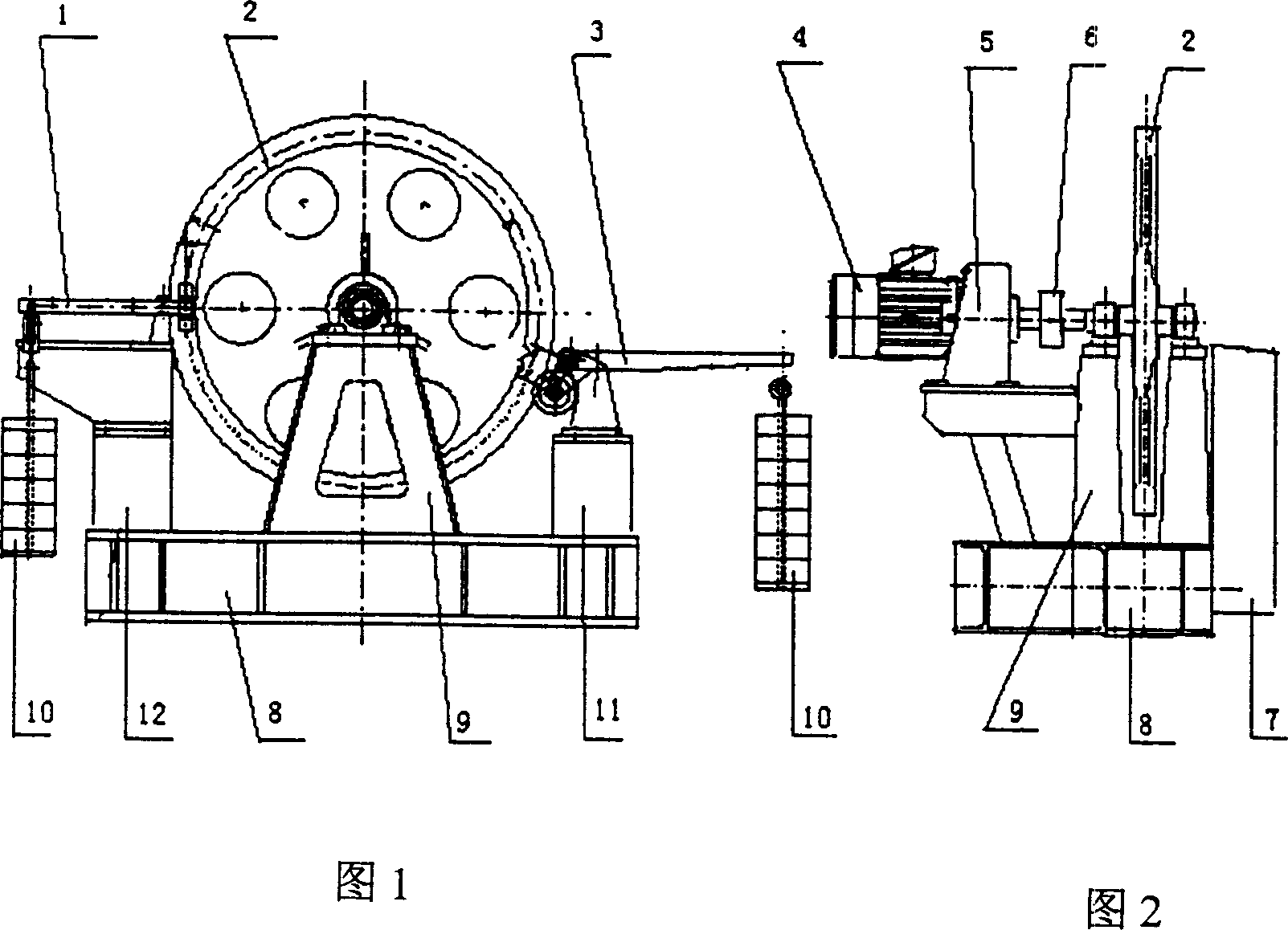

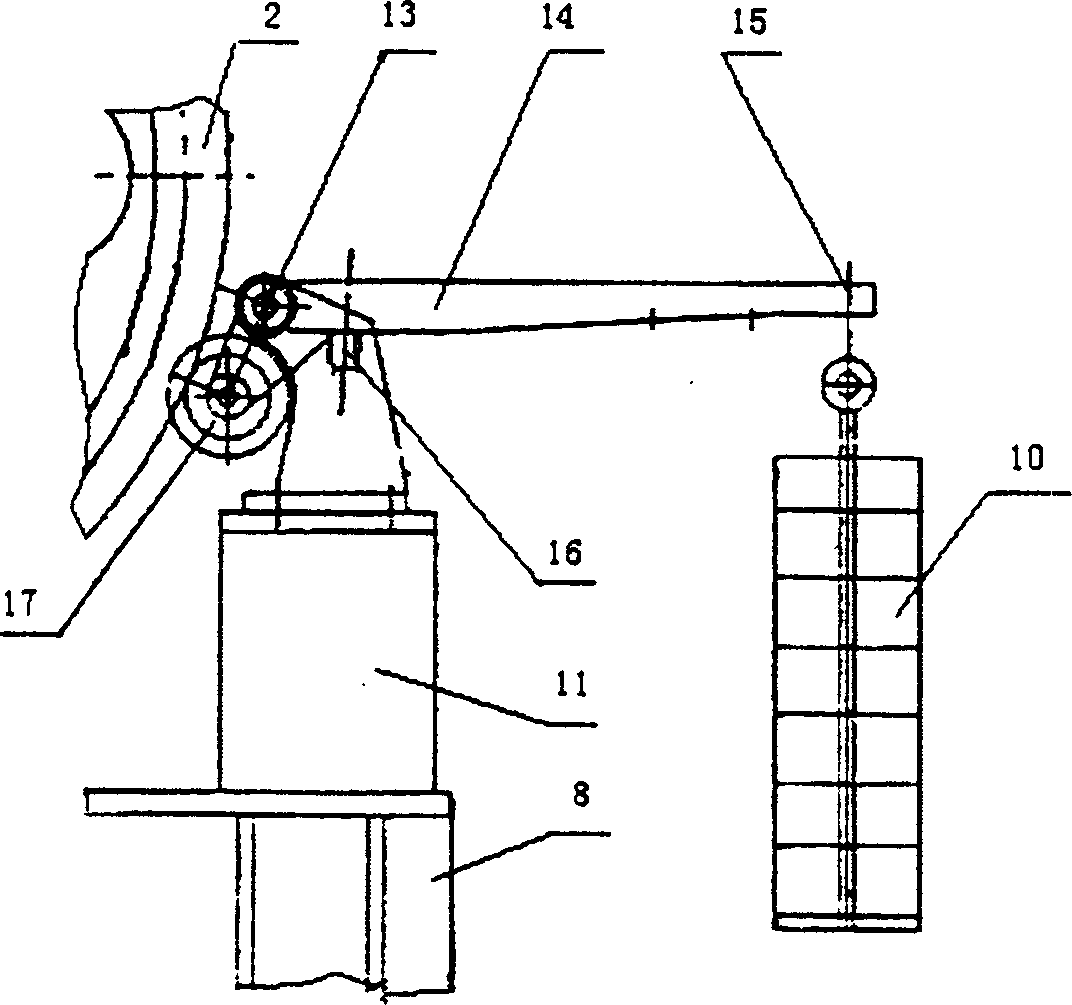

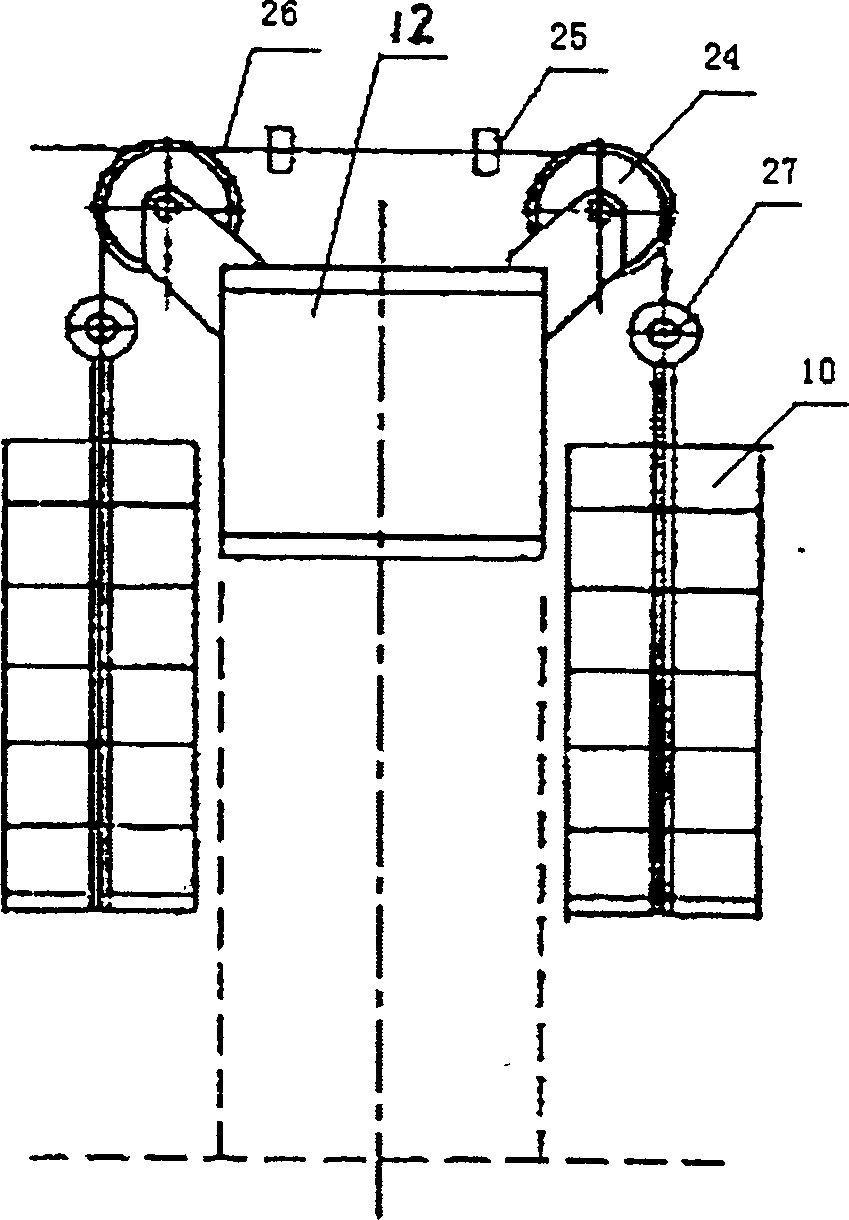

[0025] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] The realization of the technical solution of the present invention is shown in the schematic structural diagrams shown in Fig. 1 and Fig. 2 . The composite testing machine of the present invention includes a drive motor 4 , a large wheel 2 , a control box 7 , and a friction member loading device 1 and a rolling member loading device 3 . The big runner 2 is housed on the big runner support 9, and the drive motor 4 is connected to each other with the reduction box 5 and the big runner 2 coaxially through the shaft coupling 6, and the frequency converter in the control box 7 carries out speed regulation. The two ends of big runner rotating shaft are supported by rolling bearing, and rolling bearing support is connected with big runner support 9, and big runner 2 becomes driving wheel after driving motor 4 starts. The two sides of the big ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com