Steam turbine and its rotor and method for active colling the same rotor and application of the same method

A steam turbine rotor, active cooling technology, applied in the direction of machine/engine, engine starting, stator, etc., can solve problems such as increased rotor temperature and harmful heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

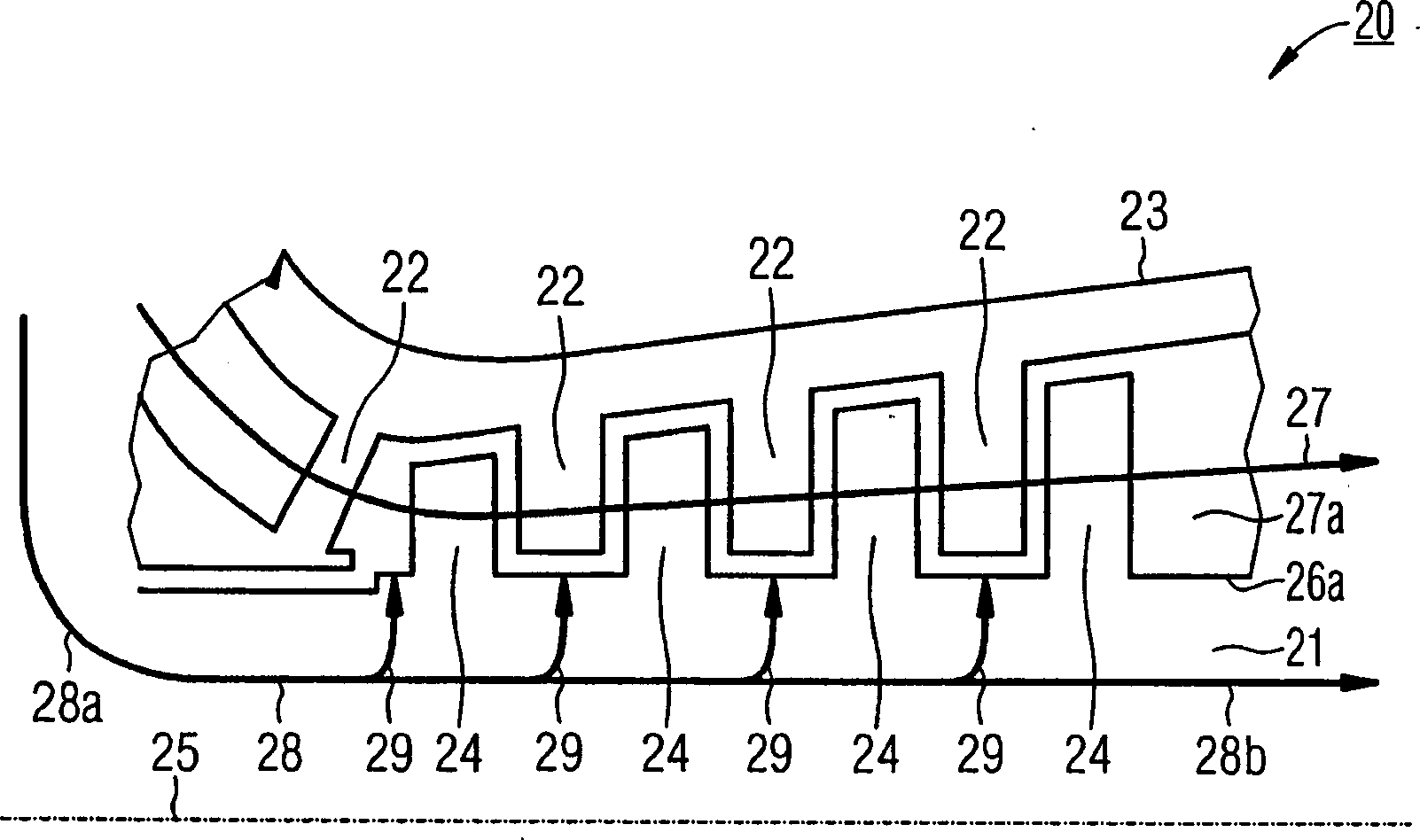

[0051] Currently known steam turbine rotors are basically made as integral rotors and have no active cooling system at all. But in the prior art according to US 6102654, such as figure 1 As shown, a steam turbine 1 is presented which has an active cooling system limited to cooling the inflow region. The steam turbine has a rotor 3 mounted rotatably on a shaft 2 on which a number of rotor blades 4 are mounted. They are arranged in a fixed housing 5 provided with guide vanes 6 . The rotor 3 is moved by means of the rotor blades 4 by the working fluid 8 flowing into the inflow region 7 . In addition to the working medium 8 , the coolant 10 flows into the working medium 8 through a separate inlet region 9 . During this process, the coolant 10 cools only the fixed first guide vane ring 11 and the shielding plate 12 through the inflow. This reduces the thermal load on the rotor 3 and the first guide vane ring 11 . Furthermore, the cooling fluid 10 is directed from the inlet reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com