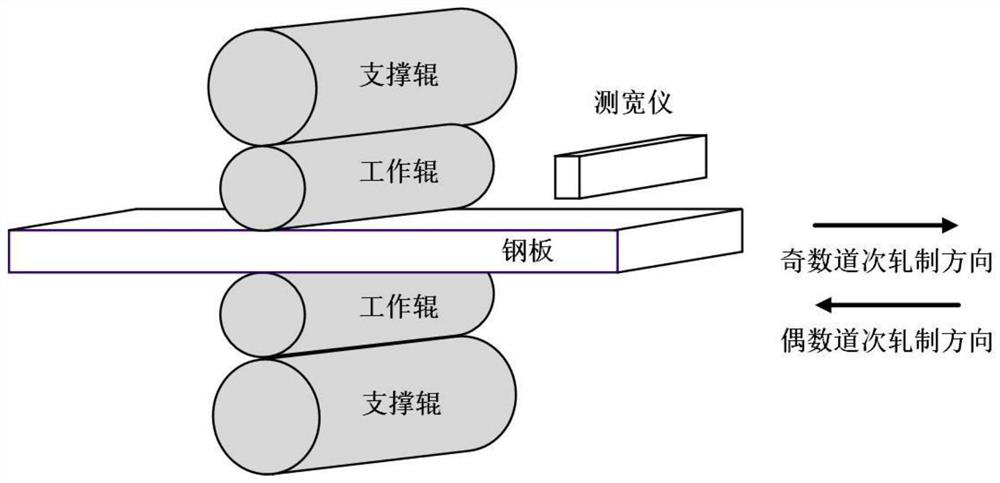

Compensation method for deviation of rolling center line of hot-rolled medium-thickness plate

A technology of rolling center line and compensation method, which is applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve problems such as unsuitable high-precision compensation methods, and achieve simple and practical calculation methods and good center line offset , the effect of improving the calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Prepare a cast slab with a thickness of 250mm and a width of 1600mm, and roll it into a Q235 carbon structural steel plate with a thickness of 30mm through a hot rolling mill. The calculation process of the roll gap leveling amount used to compensate for the offset of the center line of the steel plate is as follows:

[0039] (1) Use the width gauge to measure the offset of the center line of the slab after the first pass of rolling, respectively ΔB H =-20mm, ΔB B = 0mm, ΔB T =-40mm;

[0040] (2) According to the measured ΔB H , ΔB B and ΔB T , to calculate the slab comprehensive centerline offset ΔB C for:

[0041] ΔB C =((-20)+(-40)) / 2-0=-30mm

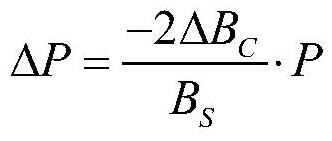

[0042] (3) Read the rolling force setting value P of the second pass in the control system = 19500kN, then the rolling force deviation ΔP on both sides caused by the offset of the center line is:

[0043]

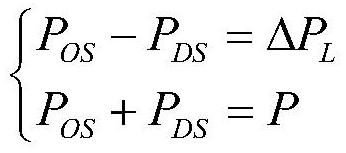

[0044] (4) According to the rolling force deviation ΔP and the total rolling force P, calculate the driving s...

Embodiment 2

[0052] Prepare a cast slab with a thickness of 250mm and a width of 2100mm, and roll it into a steel plate with a thickness of 40mm through a hot rolling mill.

[0053](1) Use a width gauge to measure the centerline offset ΔB of the slab after the first rolling pass H , ΔB B and ΔB T 30mm, -10mm and 50mm respectively;

[0054] (2) According to the measured ΔB H , ΔB B and ΔB T , to calculate the slab comprehensive centerline offset ΔB C for:

[0055] ΔB C =(30+50) / 2-(-10)=50mm

[0056] (3) Read the rolling force setting value of the second pass in the control system P = 21300kN, then the rolling force deviation ΔP on both sides caused by the offset of the center line is:

[0057]

[0058] (4) According to the rolling force deviation ΔP and the total rolling force P, calculate the driving side rolling force P DS and operation side rolling force P OS ,for:

[0059]

[0060] (5) The rigidity of the operating side and the driving side are 5500kN / mm and 5600kN / mm ...

Embodiment 3

[0066] Prepare a cast slab with a thickness of 230mm and a width of 1500mm, and roll it into a 700L automobile frame steel intermediate billet with a thickness of 45mm by a roughing rolling mill. The calculation process of the roll gap leveling amount used to compensate for the offset of the center line of the steel plate is as follows:

[0067] (1) Use a width gauge to measure the centerline offset ΔB of the slab after the first rolling pass H , ΔB B and ΔB T -15mm, 5mm and -20mm respectively;

[0068] (2) According to the measured ΔB H , ΔB B and ΔB T , to calculate the slab comprehensive centerline offset ΔB C for:

[0069] ΔB C =((-15)+(-20)) / 2-5=-22.5mm

[0070] (3) Read the rolling force setting value P of the second pass in the control system = 15750kN, then the rolling force deviation ΔP on both sides caused by the offset of the center line is:

[0071]

[0072] (4) According to the rolling force deviation ΔP and the total rolling force P, calculate the dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com