Waterproof structure of electric junction box

A technology of electrical junction box and waterproof structure, applied in electrical components, chassis/cabinet/drawer parts, base/casing, etc., can solve problems such as troublesome mutual fitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the waterproof structure of the electrical junction box of the present invention will be described in detail below with reference to the drawings.

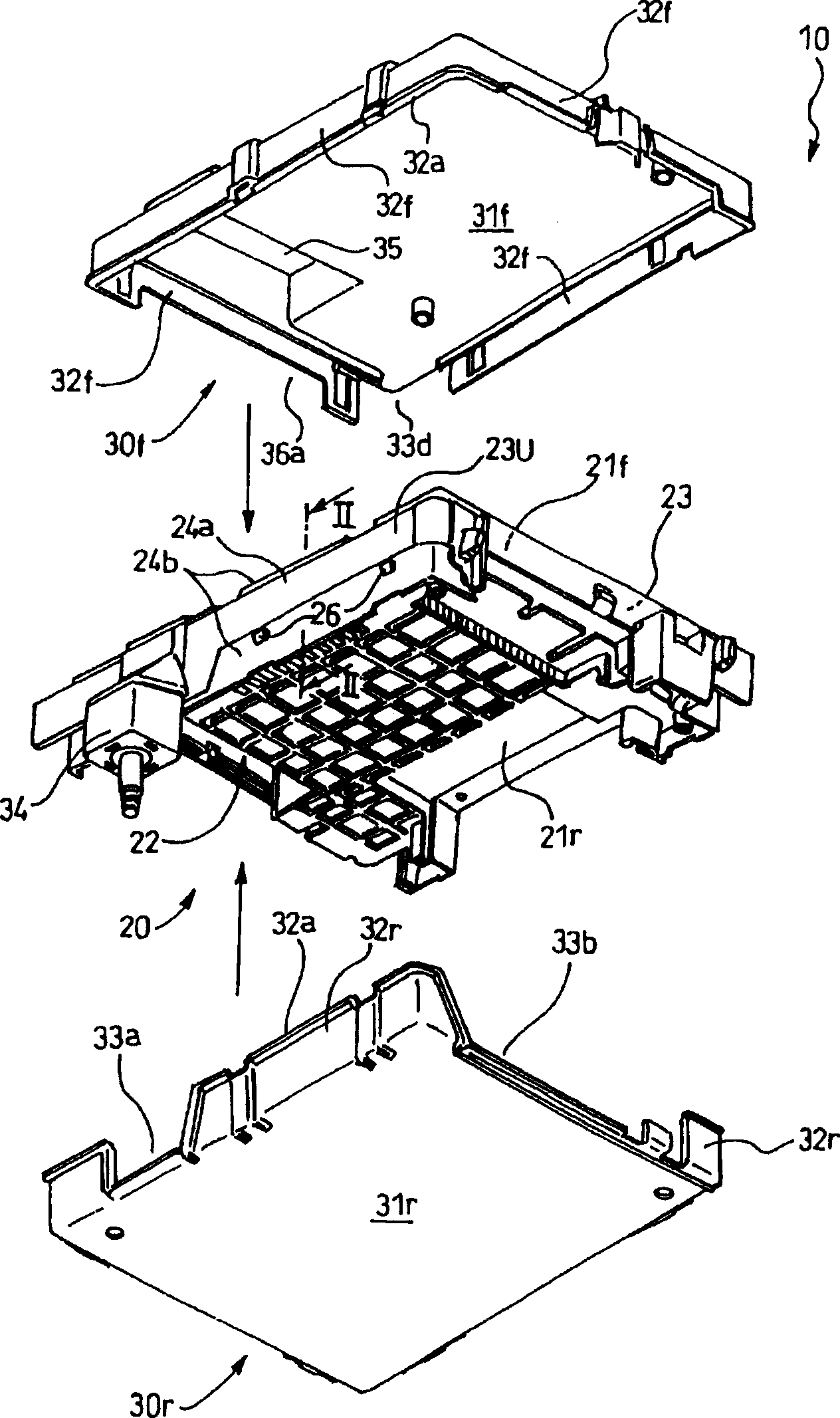

[0031] Such as figure 1 As shown, the electrical junction box 10 of the present invention has: a main body 20 having openings 21f, 21r on both front and rear sides; a pair of cover members 30f, 30r fitted together to cover the front and rear openings of the main body 20 The two outer sides of 21f and 21r. The main body 20, the cover members 30f, 30r, and the like are generally formed of synthetic resin. This electrical junction box 10 is used, for example, in a state where both openings 21f and 21r of the main body 20 are substantially along a vertical plane.

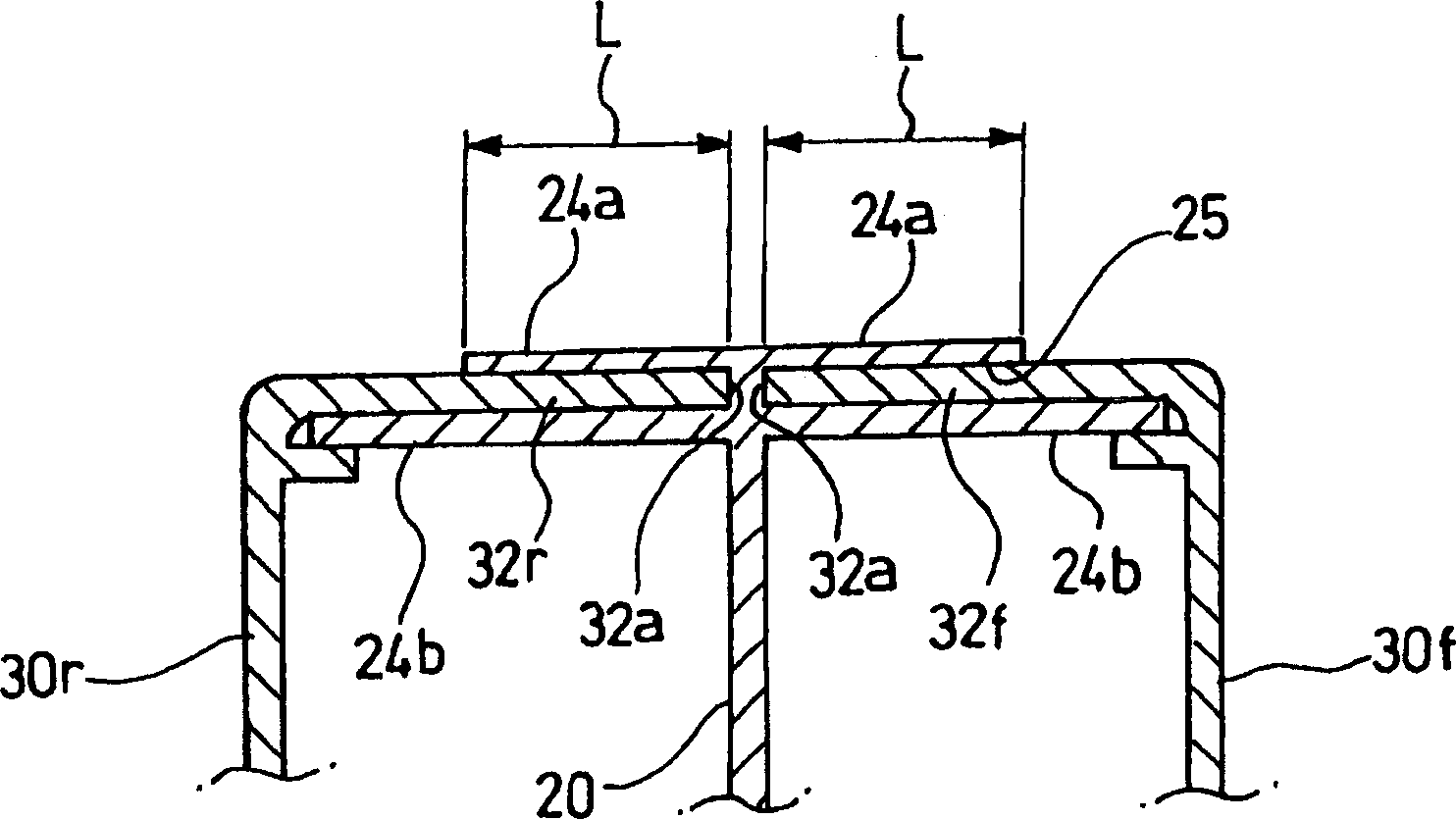

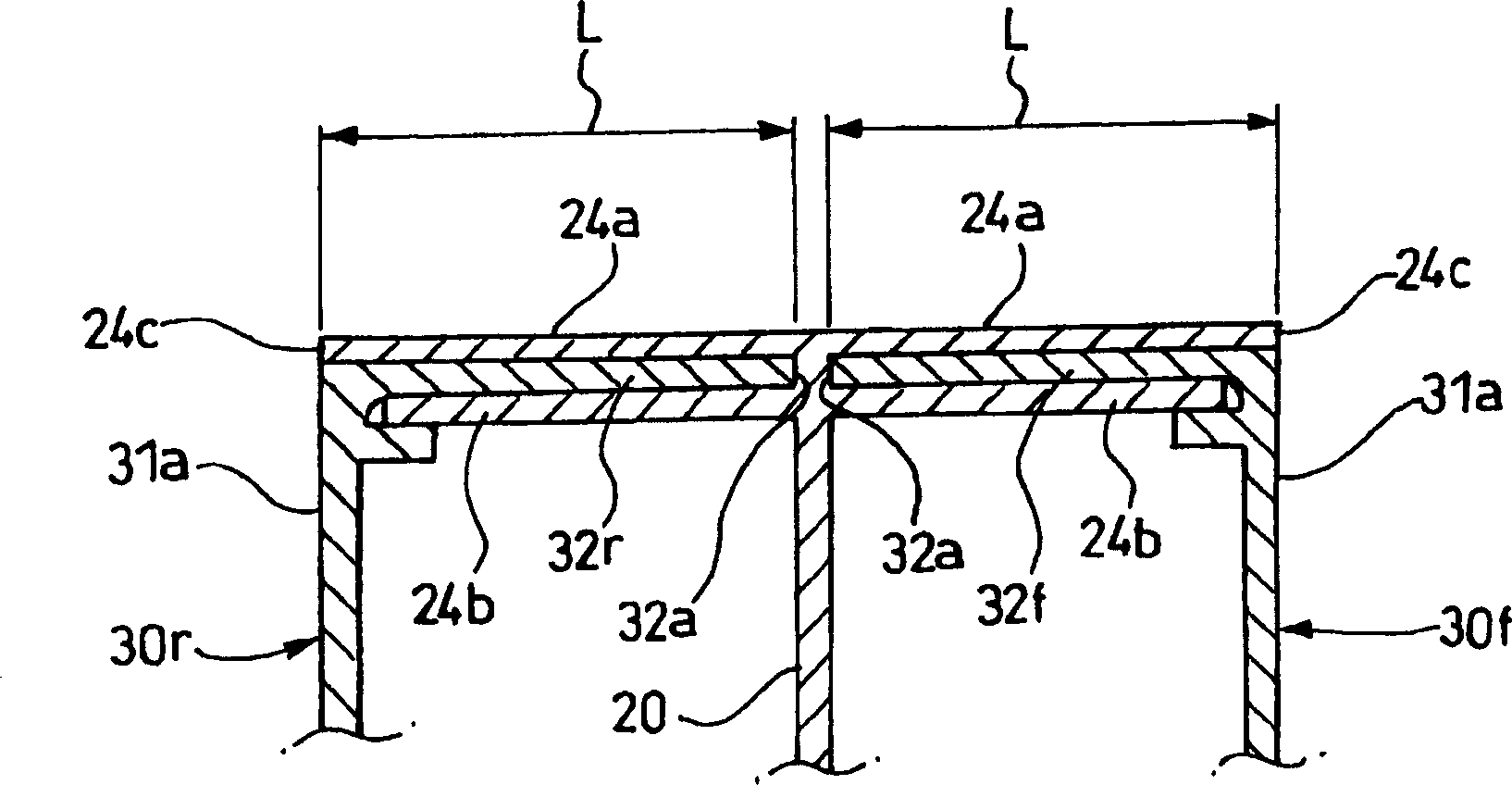

[0032] The inside of the main body 20 is provided with an electrical component storage area 22 for installing various electrical components, and the outer peripheral body wall portion 23 is set in the fitting direction as the cover components 30f, 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com