Scrolling type invisible window screen with groove on glass depression bar

A technology for glass beading and window screening, which is applied in the cleaning of windows, the arrangement of wing sashes, and insect control, etc., can solve problems such as affecting the overall flatness of the window, wasting natural resources, and taking time and effort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

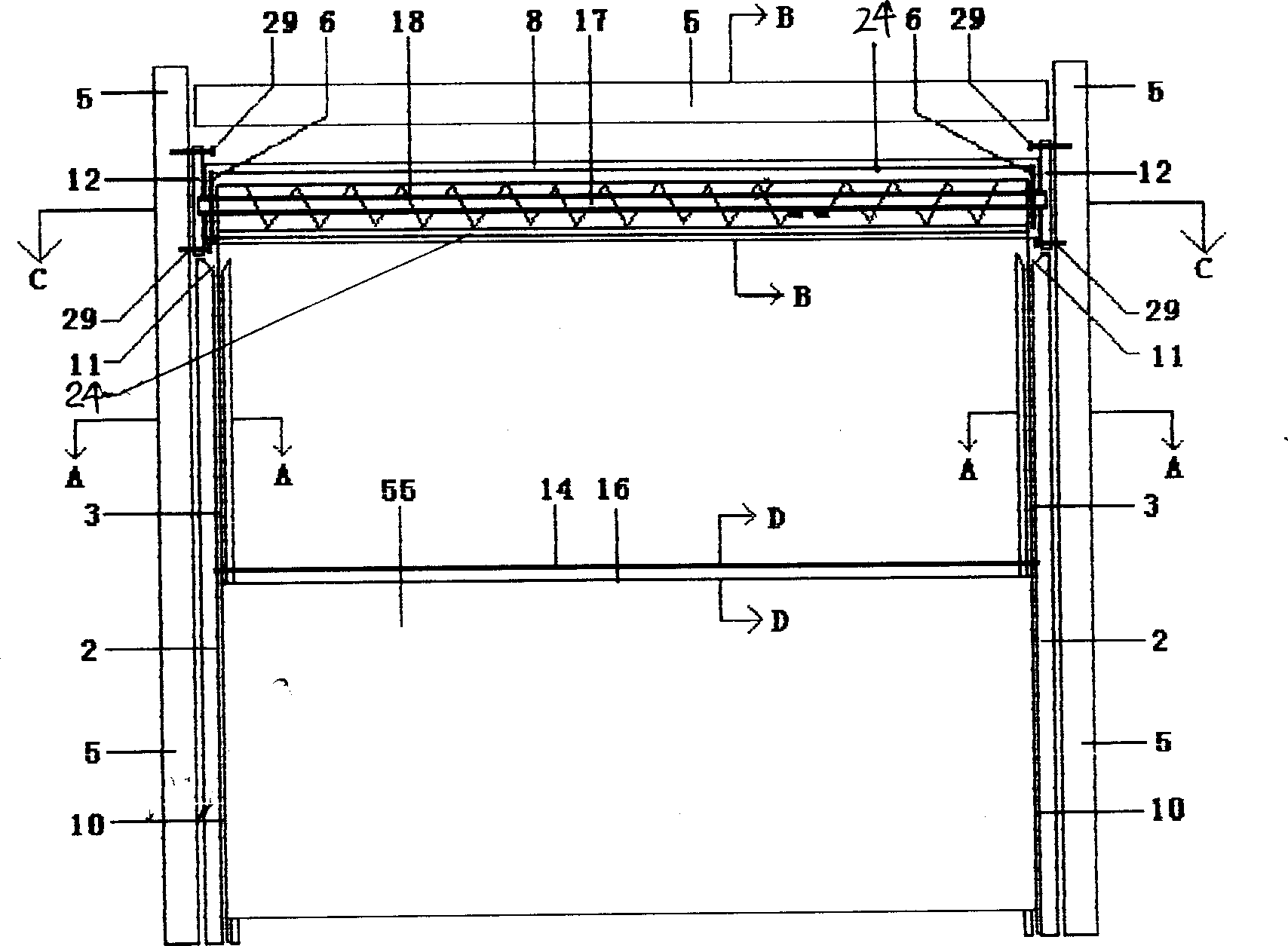

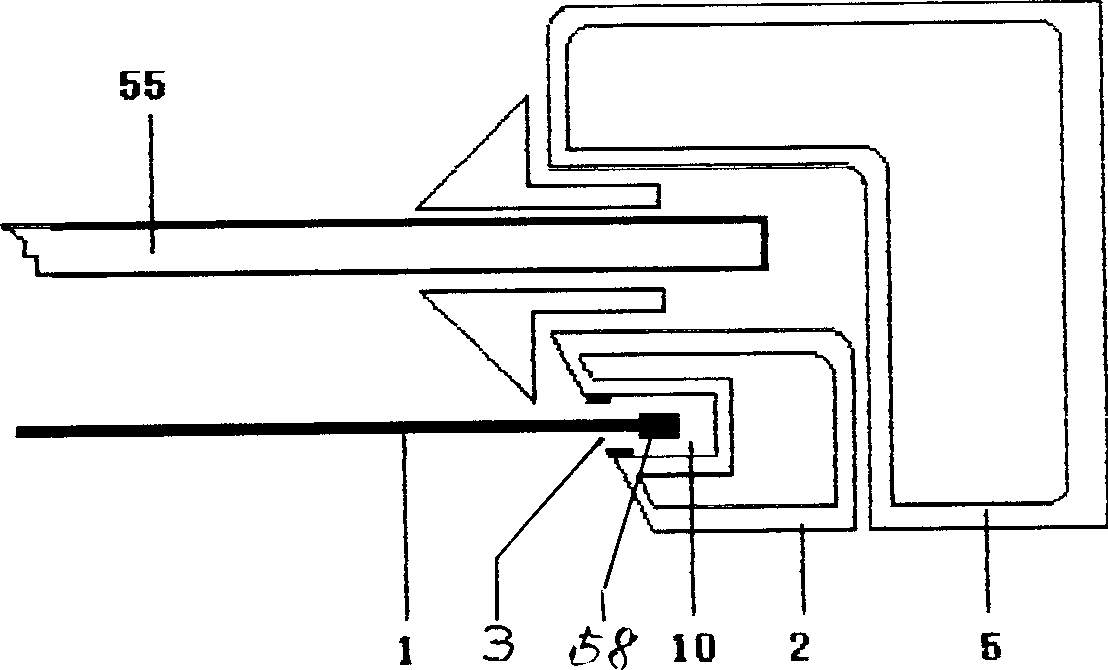

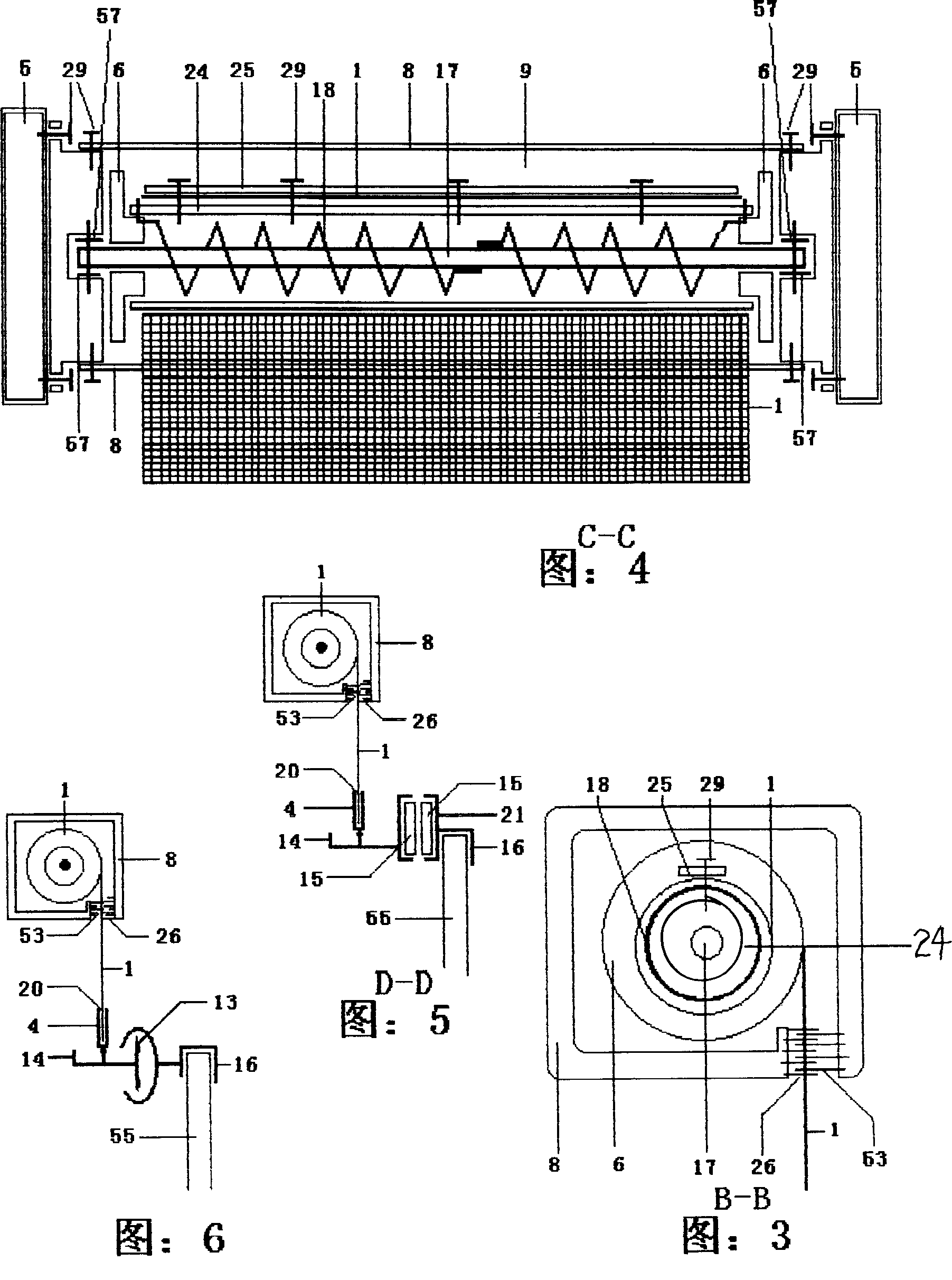

[0034] Figure 1 and Figure 2 and Figure 3 and Figure 4 and Figure 5 show the roll-type invisible window screen with grooves on the glass bead, which is composed of the window screen body 1 and the glass bead 2 which doubles as the edge motion track of the window screen and the window screen winding mechanism 17, the window screen body 1 is fixedly connected with the main shaft tube 24 on the window screen winding mechanism 17, the stopper 6 is placed at both ends of the main shaft 17, the configuration button spring 18 of the window screen body 1 is installed in the main shaft tube 24, and the coiling shell 8 Double-sided cleaning window screen tops 53 are equipped with both sides in the yarn outlet 26 of the yarn outlet, and the winding shell holder 12 is fixedly connected with the window frame beam inboard at 5 places, and is slidingly connected with the main shaft tube 24 of the window screen winding mechanism. Have the elongated narrow groove of slit 3 on the surface of gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com