Method for eliminating height difference between metal lugs on wafer and crystal grain

A metal bump, wafer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as reduced efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention provides several methods to substantially eliminate the height difference between a plurality of metal bumps on the wafer and the crystal grain, so as to achieve the effect of flattening the metal bumps.

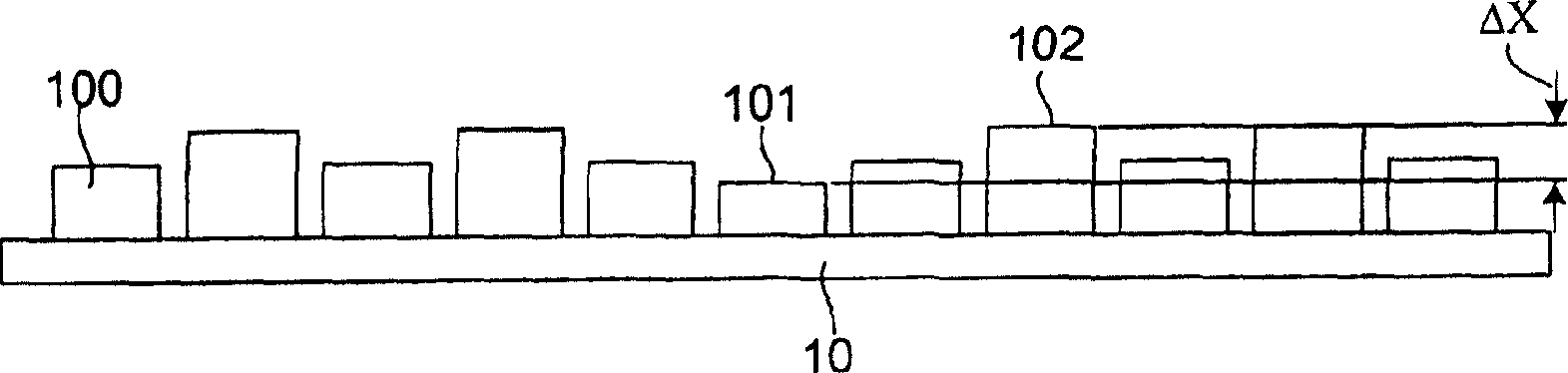

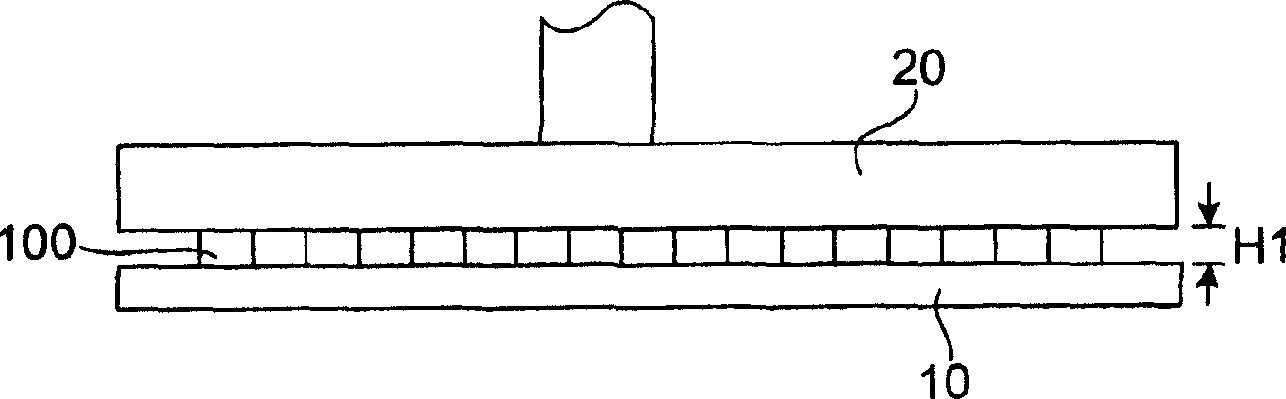

[0024] When the wafer or die has such figure 1 The height difference of the metal bump 100 can be determined by such as Figure 2A to Figure 2C The method is used to achieve the planarization effect of the metal bump. In the first embodiment of the present invention, the pressing device (not shown) has a flat pressing plate 20, such as Figure 2A shown. The planar platen 20 is aligned with the wafer or die 10 , so that the planar platen 20 is aligned with the area on the wafer or die 10 where height differences among the plurality of metal bumps 100 need to be eliminated.

[0025] Figure 2B Among them, the flat platen 20 presses the wafer or die 10 to a predetermined height H1, and the predetermined height H1 refers to the distance between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com