Energy-saving disinfection sterilization equipment for cold beverage factory by adopting electrolysis method

A technology for disinfection and sterilization and power consumption in factories. It is applied in the direction of sterilization/microdynamic water/sewage treatment, etc. It can solve the problems of polluted water quality, high energy consumption, time-consuming power consumption, etc. dirt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

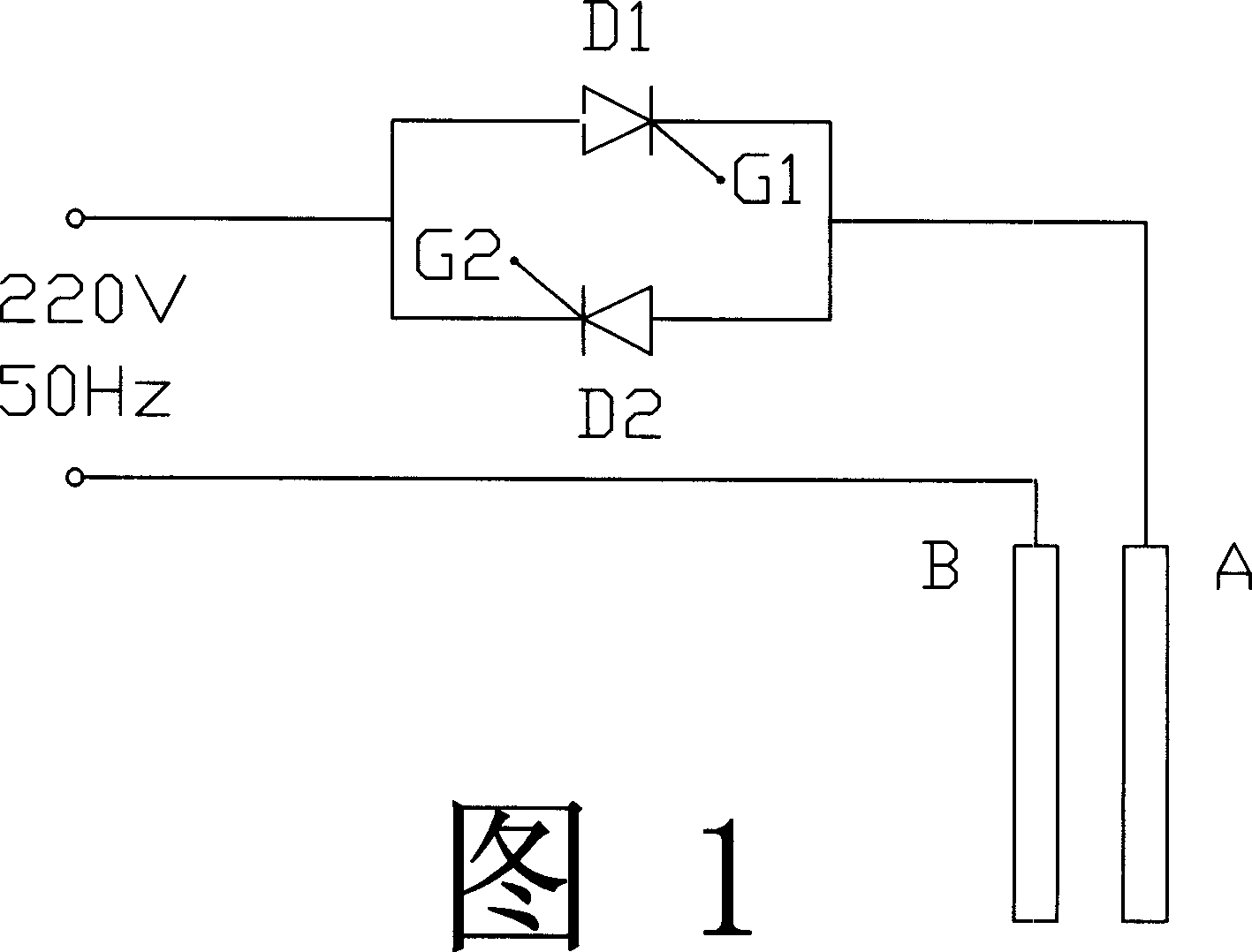

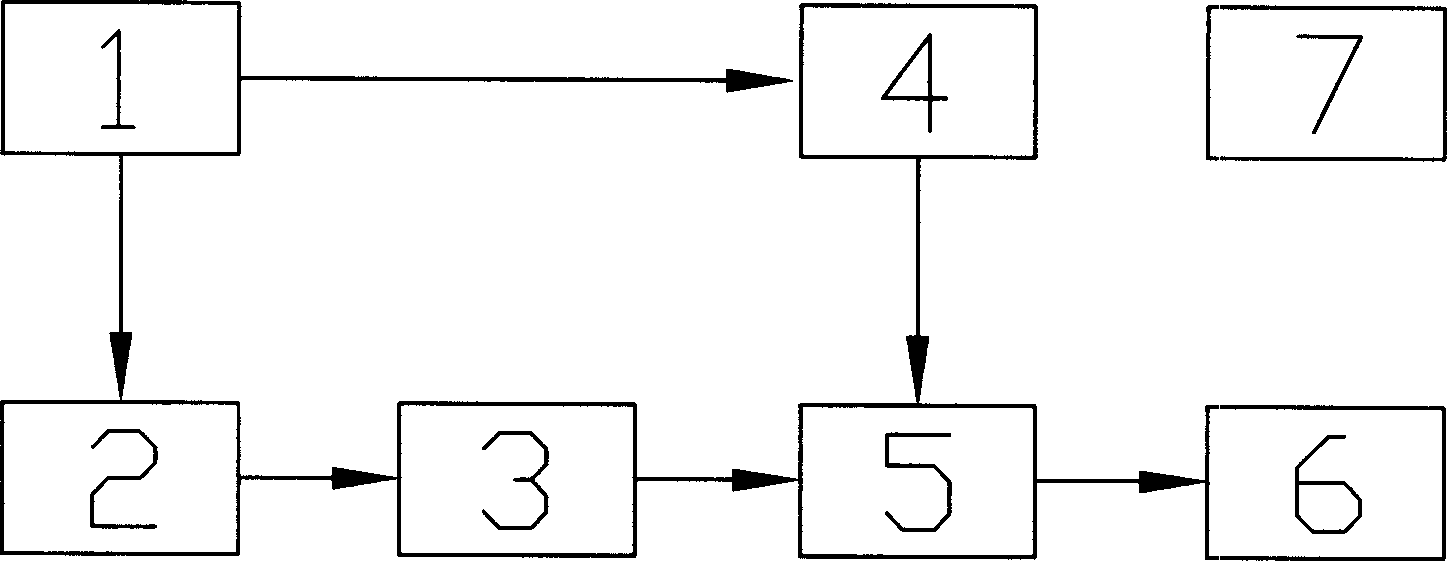

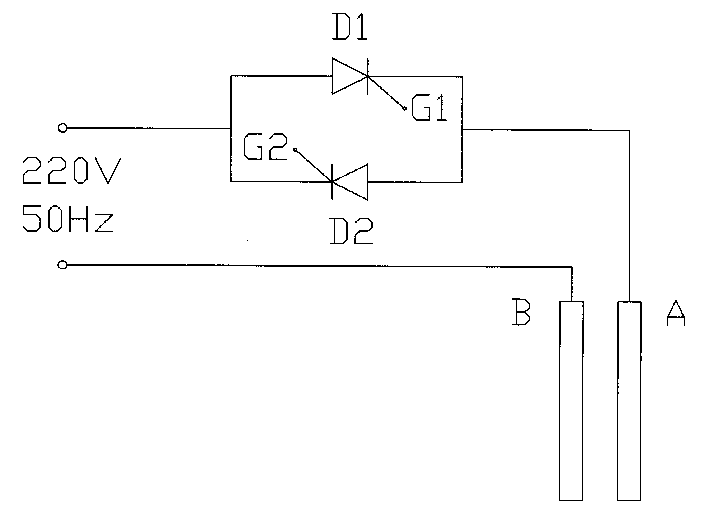

[0009] The electrical part is housed in the cover box, which mainly consists of the parts listed in Figure 1. In the figure: 1 is a power supply, 2 is a timer, 3 is a driver, 4 is a rectifier, 5 is a reversing switch, 6 is an electrode for electro-induced nascent oxygen, and 7 is a delay circuit. The power supply part of this device has two functions. One is to provide DC stable voltage for the timer composed of integrated circuits and transistors through transformers, rectifiers and voltage stabilizers. The voltage level should be determined according to the specifications and models of the selected integrated circuit transistors. . Another function of the power supply is to provide 50Hz, 220V mains power for the rectifier. The two paths do not interfere with each other, but work together. In order to avoid the use of high-power transformers, a silicon controlled rectifier is used to directly rectify the AC mains. The rectification is half wave. In a certain period of tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com