Oil-water separatior for separating micro-seston of bilge

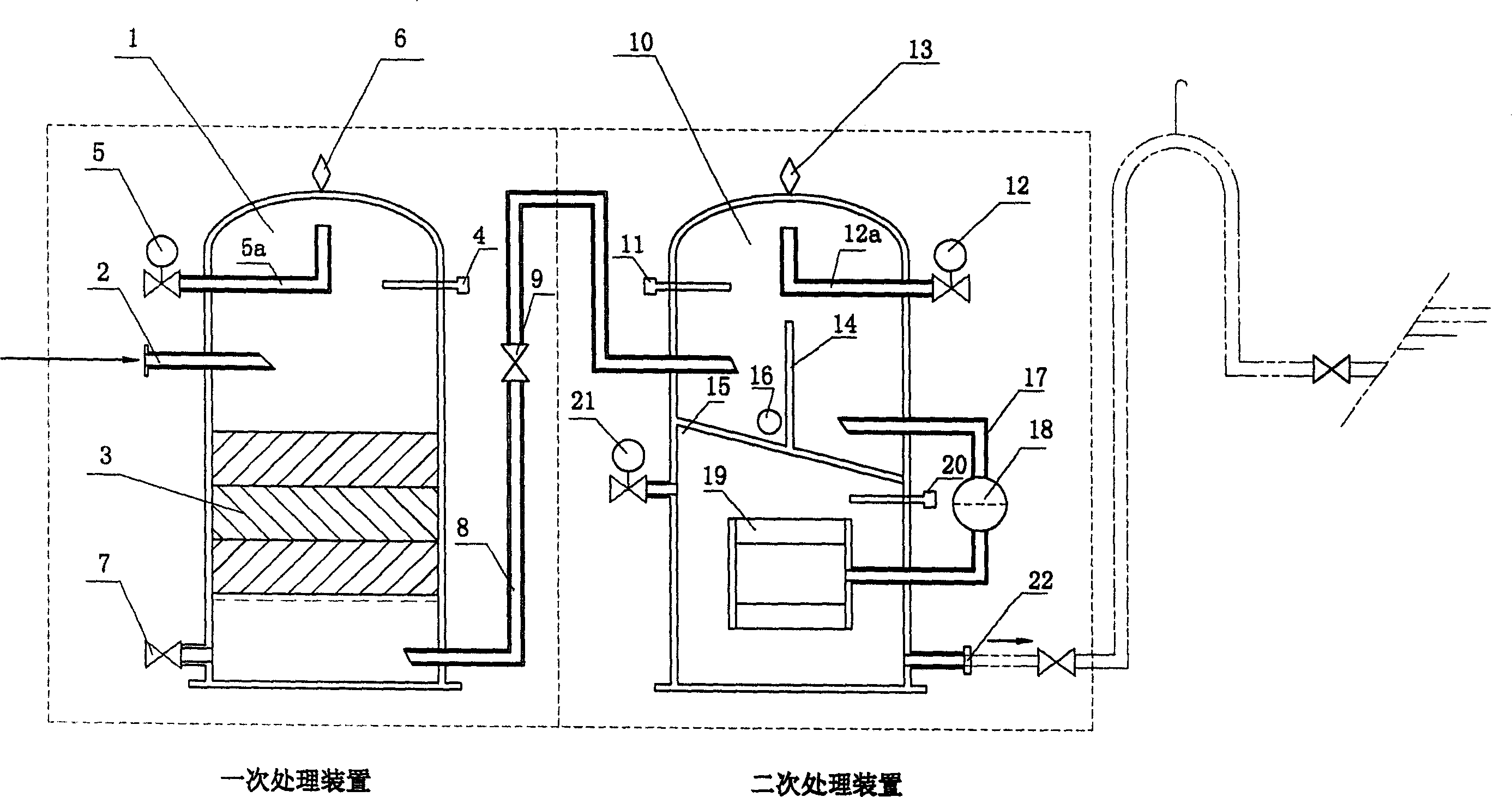

An oil-water separation device and tiny technology, which is applied in water treatment devices, transportation and packaging, ship parts, etc., can solve the problem that the concentration of water and oil cannot reach the discharge standard, the clogging of coalescers or adsorption materials, and the deterioration of gravity separation performance, etc. problems, achieve the effect of maintaining stable degreasing performance, preventing adverse effects, and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

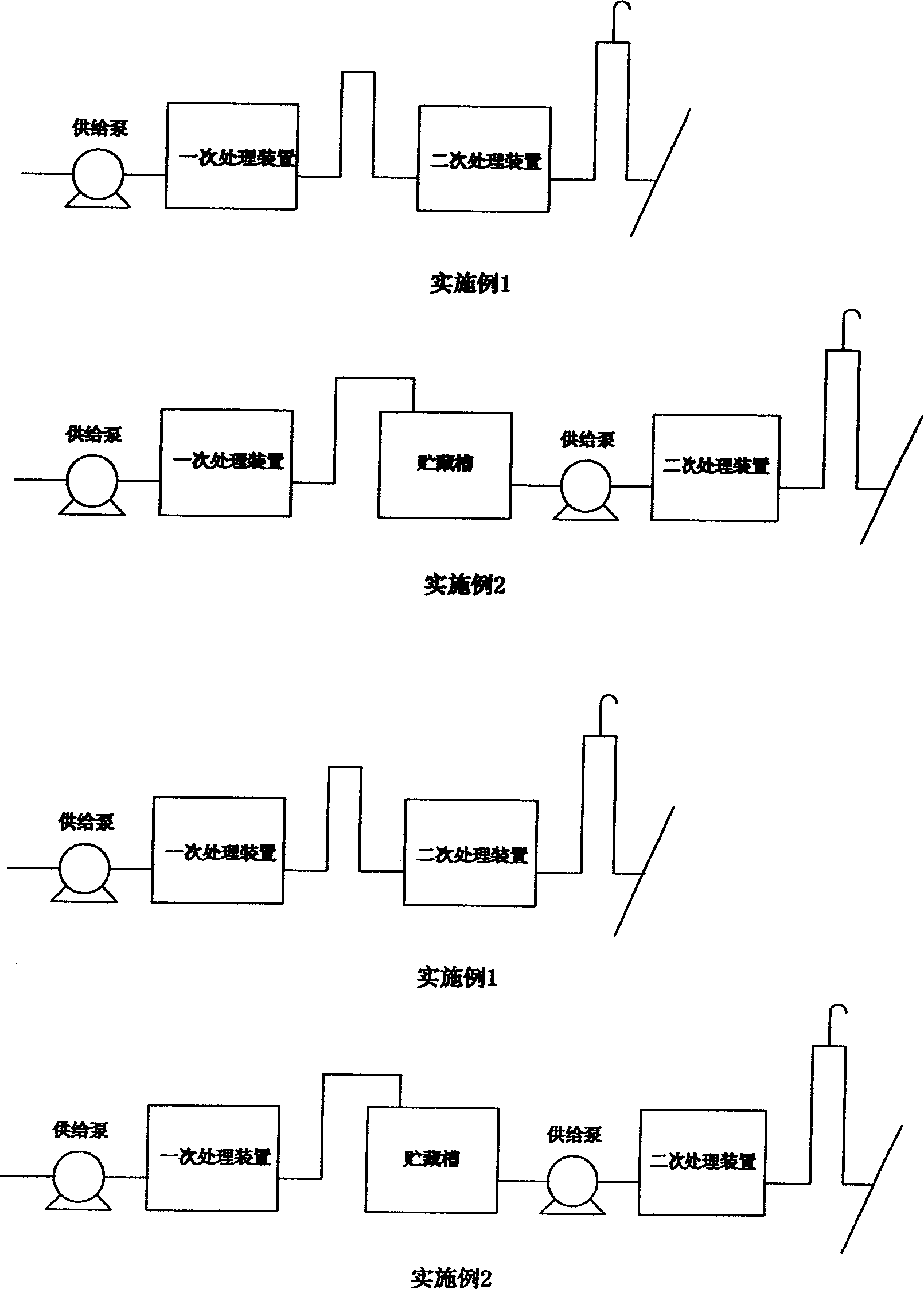

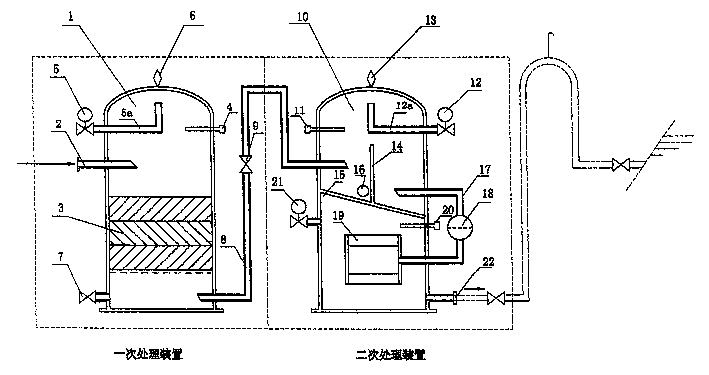

[0027] The preferred pipeline connection structure shown in Example 1, as shown in the above examples, flows from the sand filter device of the primary treatment device to the type-approved oil-water separation device of the secondary treatment device.

Embodiment 2

[0028] The pipeline connection structure shown in Example 2 is a licensed oil-water separator that allows the treated water of the sand filter device of the primary treatment device to be temporarily stored in the storage tank, and then flows into the secondary treatment device from the storage tank. Adopting this structure requires two supply pumps, so the operation and the like are more complicated than in Embodiment 1.

Embodiment 3

[0029] The pipeline connection structure shown in Embodiment 3 is a sand filter device flowing from the type-approved oil-water separation device of the secondary processing device to the primary processing device. According to this structure, the filter and the coalescer installed in the secondary treatment device will accumulate microscopic objects, requiring frequent maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com