Motor with brake

A motor with brake technology, which is applied in the field of motors, can solve the problems of increased processing costs and difficulties in making bosses at the bottom of the tank surface, and achieves the effect of convenient processing and stable axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

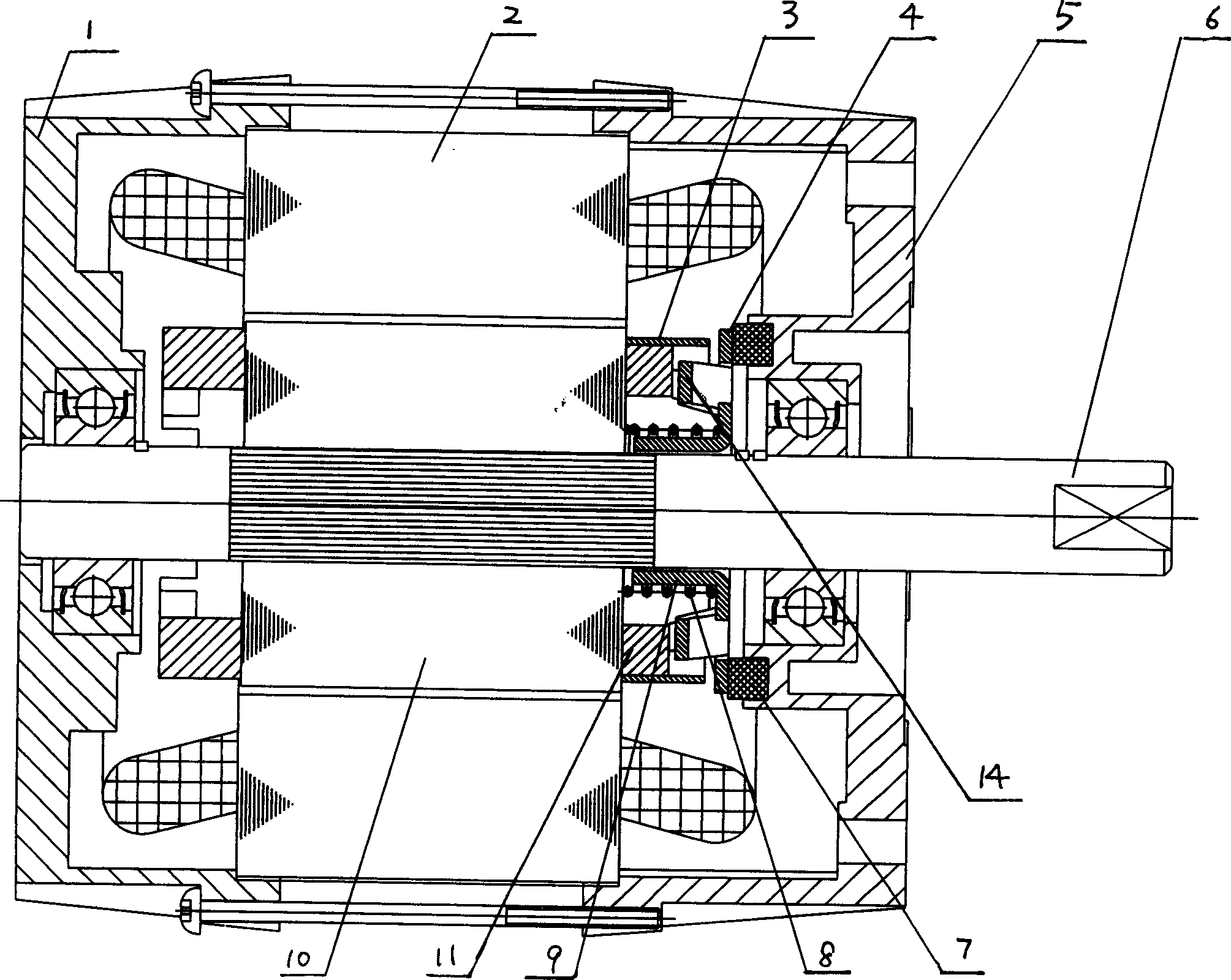

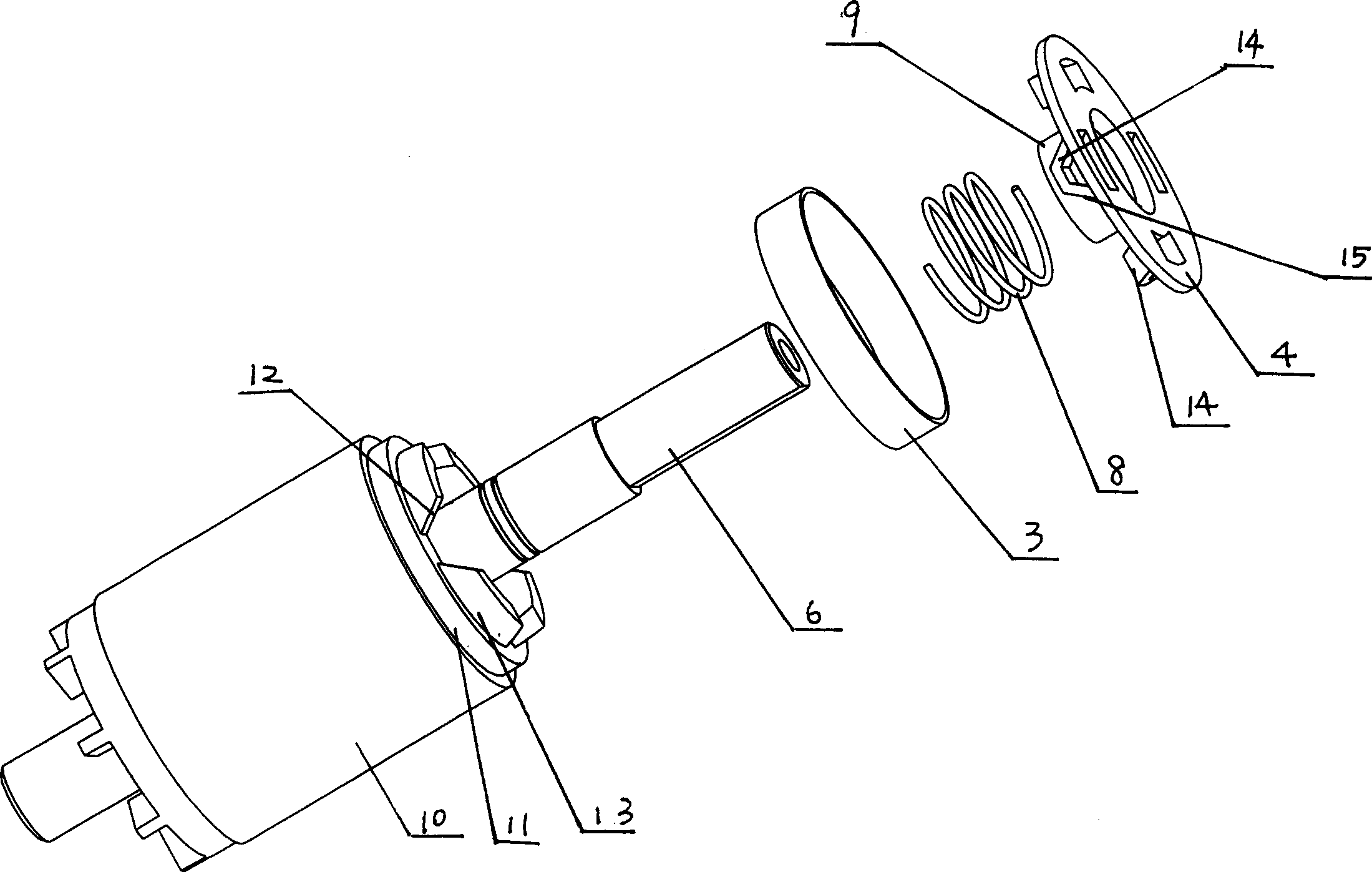

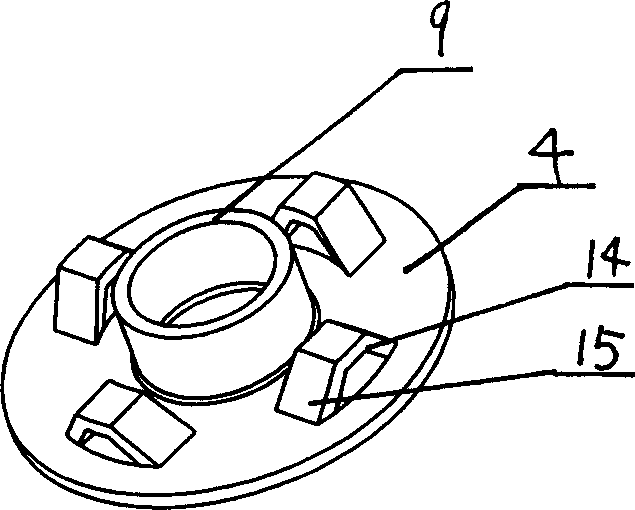

[0016] Referring to the accompanying drawings, a motor with a braking device includes a stator 2, a rotor 10, a shaft 6 fixedly connected to the rotor 10, a short-circuit ring 11 fixedly connected to the end of the rotor 10, and a brake body 4 sleeved on the On the shaft 6 of the brake body 4, the side facing the short-circuit ring 11 is provided with a boss 14 protruding toward the short-circuit ring, and the boss 14 is provided with at least one slope 15, and the short-circuit ring 11 is provided with a boss 13, the projection 13 is provided with at least one wedge surface 12; a friction body 7 is arranged between the brake body 4 and a fixed front end cover 5 relative to the stator 2, and one is used to make the brake body 4 have a tendency The spring 8 leaning against the friction body 7 is arranged between the rotor 10 and the brake body 4, and a magnetically conductive ring 3 is also provided. The magnetically conductive ring 3 and the brake body 4 are of a separate struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com