Wheel motor for electric driven vehicle

A technology of wheel motors and electric vehicles, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., and can solve problems such as small torque, polluting the environment, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

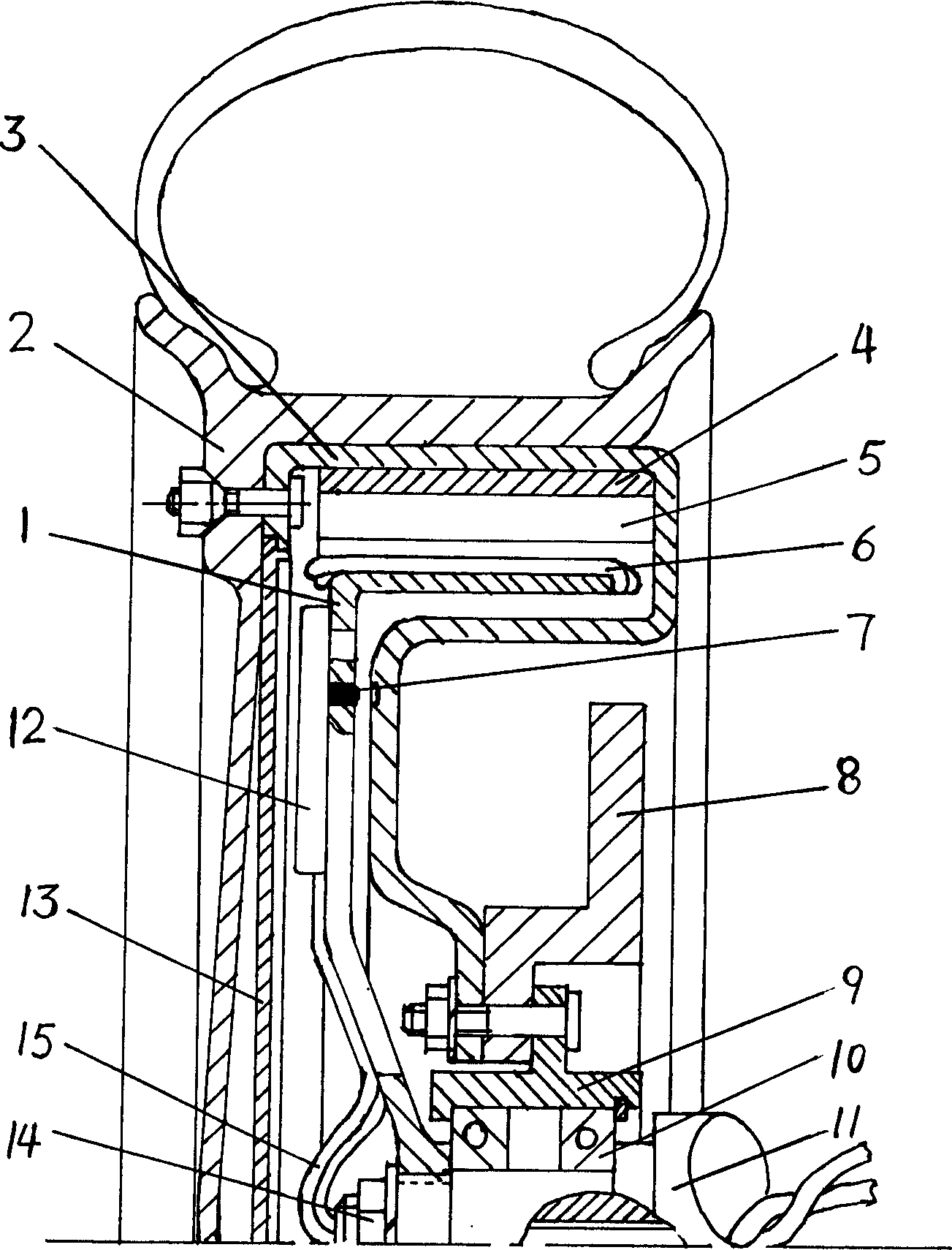

Embodiment Construction

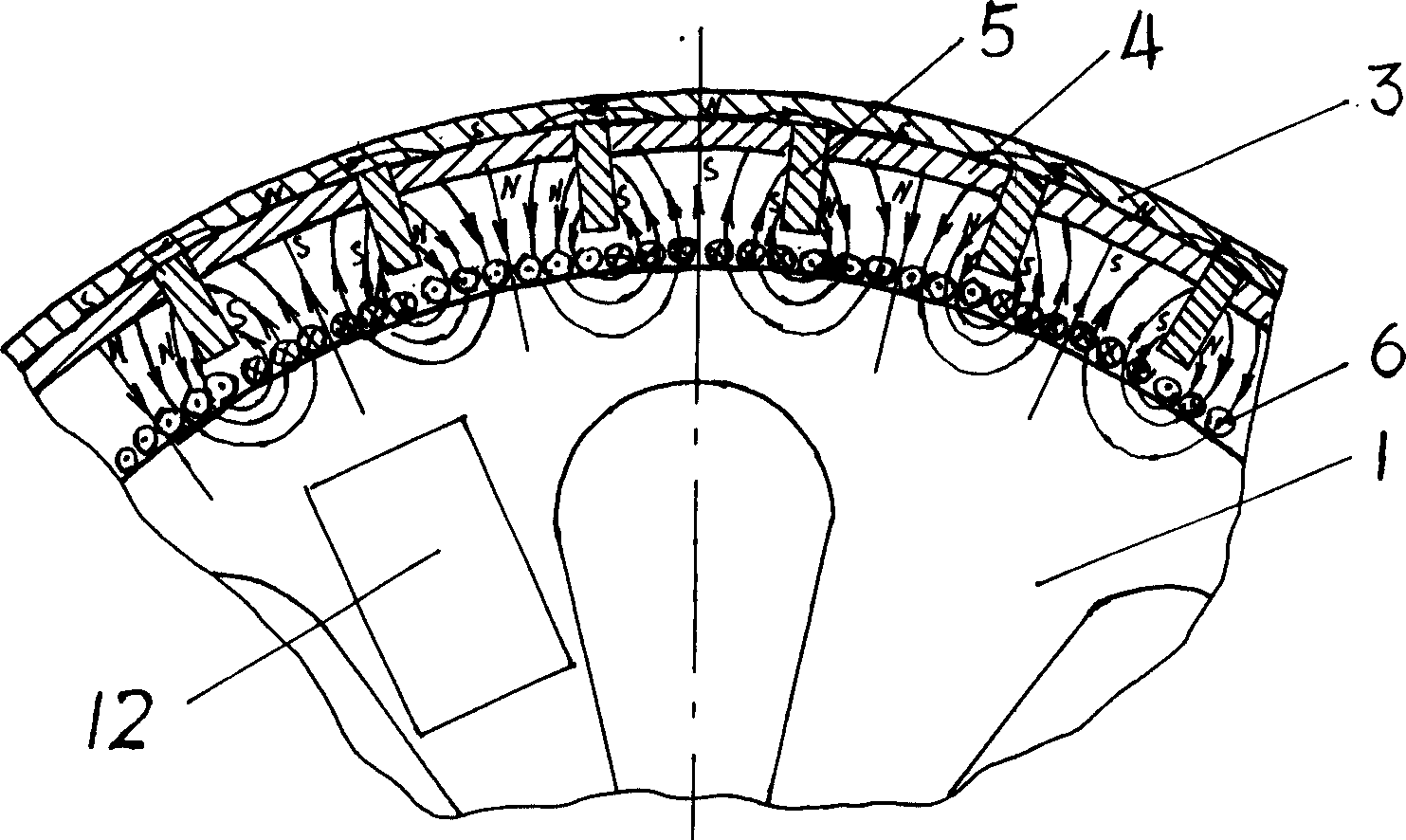

[0008] Such as figure 2 As shown, the inner wall of the outer circumference of the outer rotor (3) of the cylindrical DC motor is uniformly fixed with tangentially placed strip permanent magnets (4) and radially placed strip permanent magnets (5), which are arranged alternately to form an opening The inward tooth-shaped structure, the adjacent permanent magnets are placed in the same magnetic pole pair, so that a strong radial magnetic field is formed at the opening, and the permanent magnets (4, 5) use high-strength permanent magnets (such as neodymium iron boron rare earth permanent magnets). Magnet), help to improve the efficiency and maximum starting torque of the motor. The width of the opening is an integer multiple of the thickness of the permanent magnet (5) placed radially (generally 4-10 times is appropriate, and 5 times is taken as an example in this example). The outer rotor (3) shell is made of steel, which can reduce magnetic flux leakage. The rotor outer cover (13)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com